| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-2

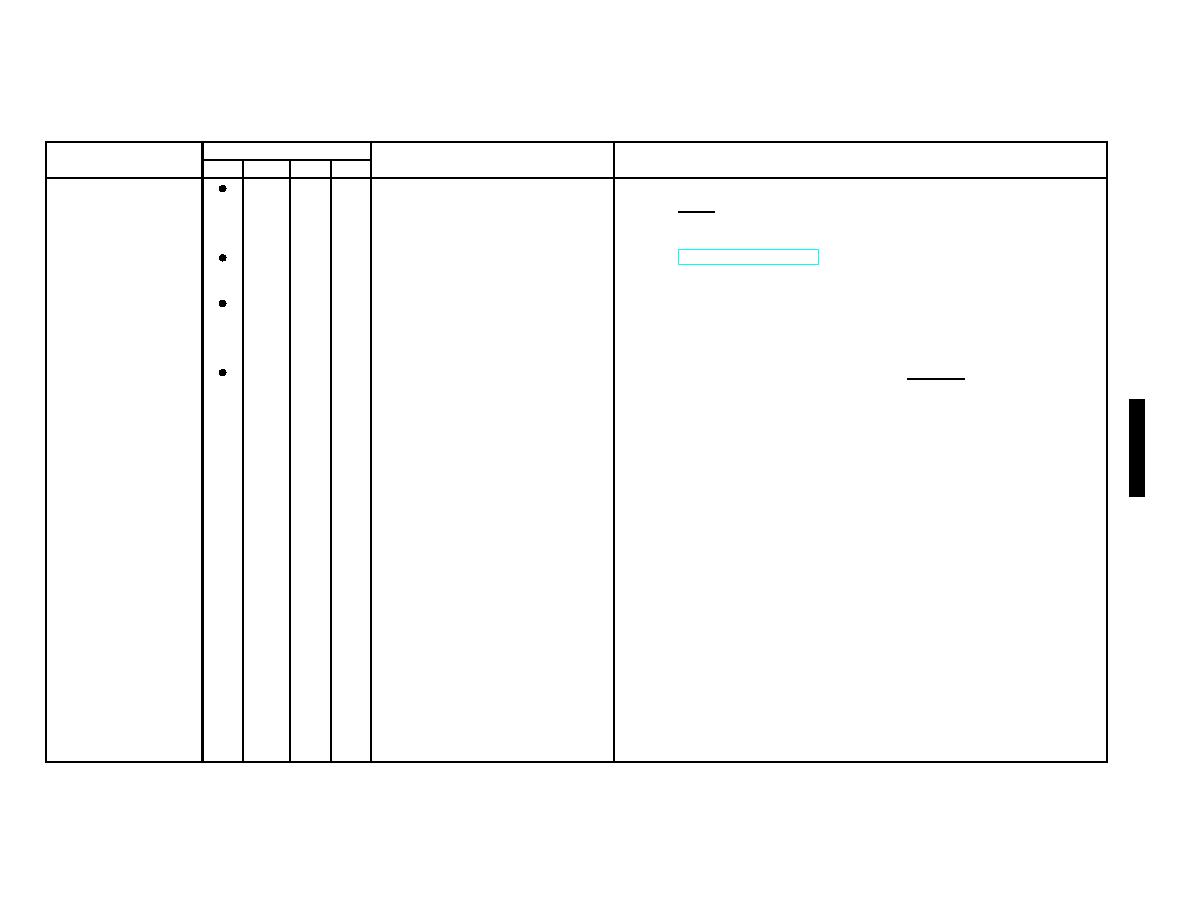

Table 2-1. Preventive Maintenance Checks and Services

Item

Interval

Items To Be

No

D

W

S

A

Inspected/Serviced

Procedures

1

Oil level

Before engine startup and engine shutdown, check oil level with the

dipstick after oil has settled into the sump. Keep oil level as near the

upper mark as possible.

2

Water pump operation

Refer to TM 55-1905-223-10

3

Oil pressure

With the engine running, check oil pressure at the oil pressure gauge

on top of the gear box. Pressure should read 260 to 280 psi in all

operational modes: neutral, ahead, and astern.

.

4

Inspect the gearbox carefully. Look for; anything that appears to be

damaged, leaking, broken, or out of the ordinary.

NOTE

An alarm sounding indicates the filter

cartridge is fouled and must be cleaned

(PMCS 6).

Change 2

2-4

|

||

|

||