| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-3

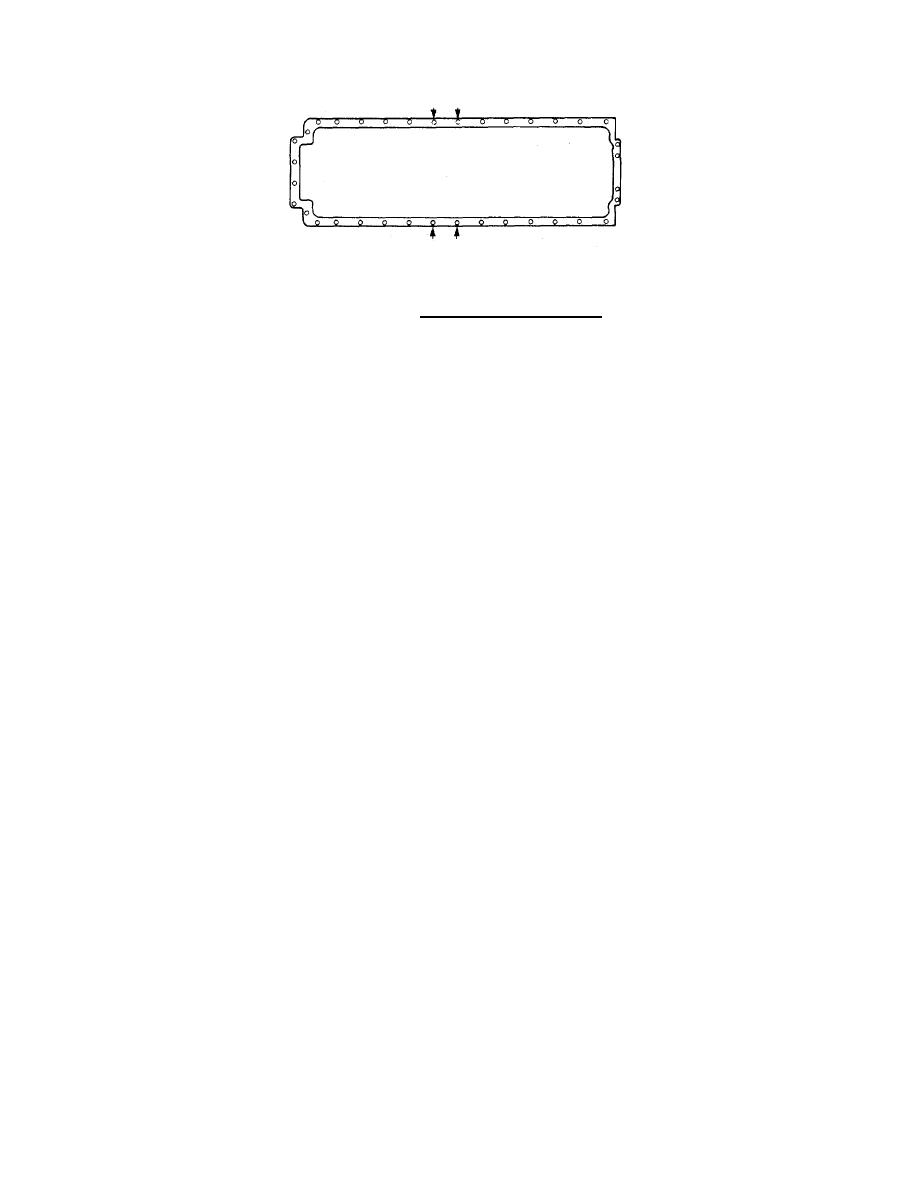

FIGURE 3-46. Middle Oil Pan Capscrews.

(7)

Tighten the capscrews that hold the oil pan buttress to the flywheel housing buttress to 70 to 80 ft-lb

(95 to 108 N ) torque.

M

(8)

Tighten the capscrews that hold the oil pan to the rear cover plate to 15 to 20 ft-lb (20 to 27 N )

M

torque.

e. Install the nonmetallic hose assembly (8) and flange to tube elbow (6) as follows:

(1)

Apply clean lubricating oil to the hose nuts and sleeves. Install the oil pan flange (6) onto the hose

nut but do not tighten.

(2)

Install the oil pan flange (6) and a new gasket (5) with capscrews (7) onto the oil pan. Do not

tighten the capscrews.

(3)

Push the hose connector into the oil pump adapter until it is against the bottom of the adapter.

Hand tighten the nut. Then tighten the nut an additional 1 to 1-1/4 turn.

(4)

Hand tighten the hose nut on the oil pan flange (6). Tighten the capscrews (16) that hold the flange

to the oil pan to 30 to 35 ft-lb (41 to 47 N ) torque. Tighten the hose nut until it is against the stop

M

on the suction flange.

f.

Install thread machine plug (10), pipe plug (11), and valve (12) into the oil pan and connect the sump

pump line.

3-89

|

||

|

||