| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

Table 2-2. Troubleshooting-CONT

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

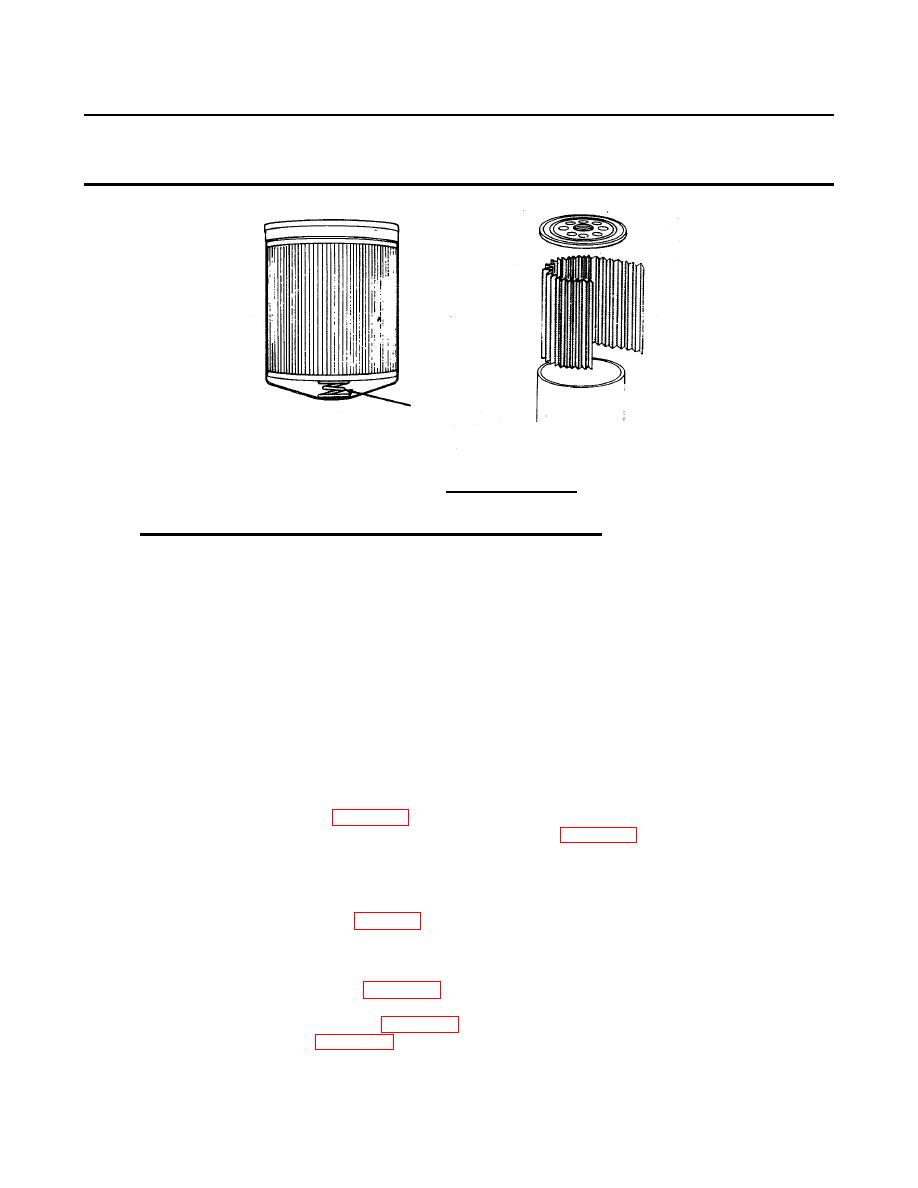

FIGURE 2-3. Oil Filter/Cooler.

Metal

Probable Source

Reference

Copper

Bearings and Bushings

Piston Rings

Iron

Cylinder Liners

Lead

Bearing Overlay Material

Aluminum

Piston Wear or Scuffing

NOTE

Sample engine oil and send to the Army Oil Analysis Program to

determine metal type.

b. Check for plugged oil cooler by visually inspecting the cooler core for plugged or damaged tubes.

Replace oil cooler core (para. 2-30).

c. Check for leaking oil cooler core. Replace oil cooler core (para. 3-14).

8. Lubricating oil temperature above normal.

STEP 1. Check for incorrect oil level.

Add or drain oil as necessary (Table 2-1, Item 4).

STEP 2.

Check for high engine coolant temperature.

a.

Check thermostat operation (para. 2-24).

b.

Check for damaged coolant hoses and tubings.

c.

Tighten loose water pump belt (para. 2-29).

d.

Replace water pump (para. 2-29).

2-32

|

||

|

||