| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

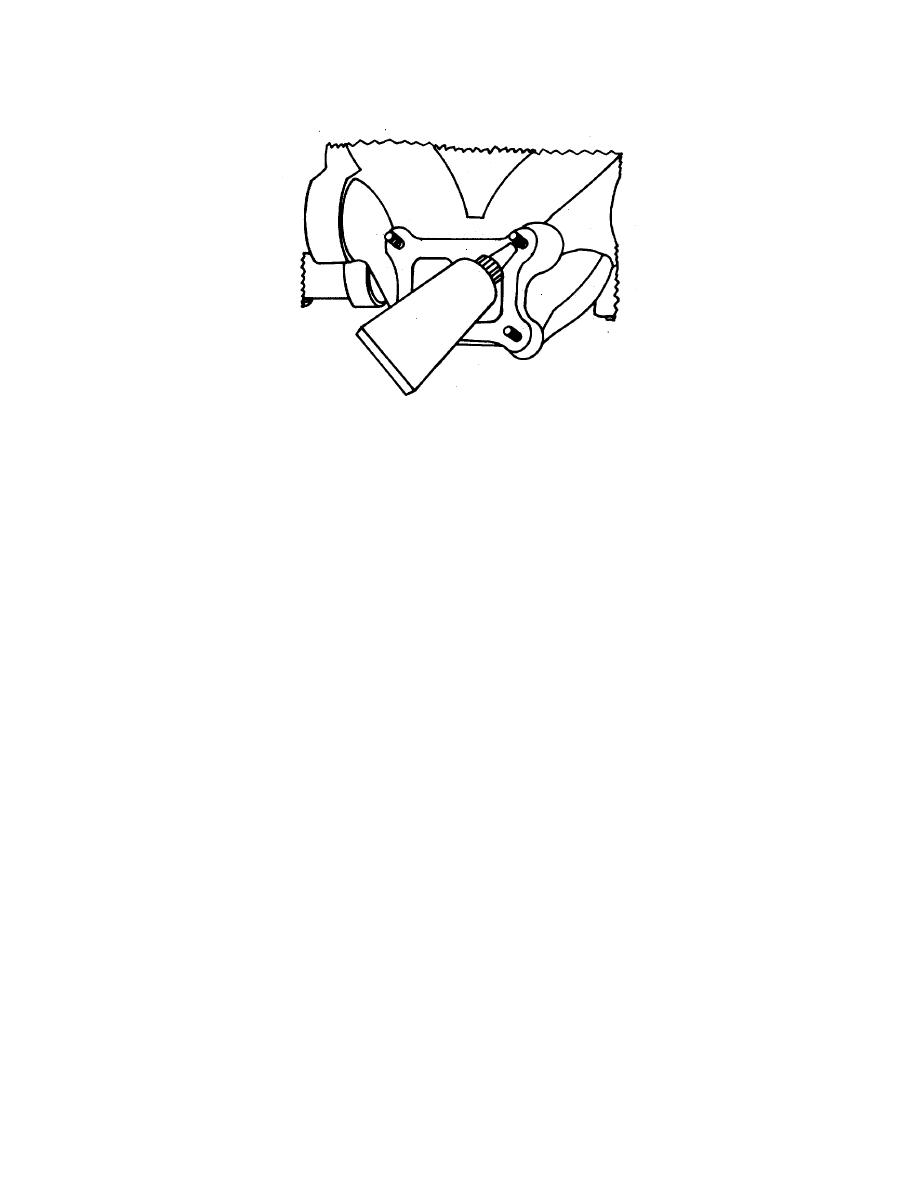

FIGURE 2-18. Anti-Seize Application.

NOTE

The centerline of the oil drain hole must be within 30 degrees of vertical when

the turbocharger is installed onto the engine.

d. Install turbocharger (3) on mounting studs (15) and replace sleeve nuts (13), but do not tighten at this

time.

e. Install air crossover hose (6) with clamps (4), bolts (5) and nuts (7). Tighten bolts (7) to 70 in-lb (8

N ) torque.

m

f. Install exhaust piping (11) with V-clamp (12) and secure.

g. Install thermocouple (10) in exhaust pipe connection (11).

h. Install engine air intake pipe (1) with clamp (2). Tighten clamp (2) to 32 ft-lb (44 N ) torque.

m

i. Tighten sleeve nuts (13) securing turbocharger (3) mounting flange to exhaust manifold to 32 ft-lb (44

N ) torque.

m

j. Install gasket (30), oil drain bent metallic tube (29) and secure with two assembled washer screws to

32 ft-lb (44 N ) torque.

m

k. Install nonmetallic hose (21), hose clamps (20 and 22) and pipe elbow (19). Tighten hose clamps to

32 in-lb (4 N ) torque.

m

l. Install oil drain loop clamps (23 and 24) and secure with hex nut (18), lockwasher (25), flat washer (26)

and hexhead capscrew (27).

m. Install pipe to hose elbow (16) and pipe to tube elbow (8).

n. Connect oil supply nonmetallic hose (9) to pipe to hose elbow (16).

o. Pour 2 to 3 ounces of clean engine oil into oil supply nonmetallic hose assembly (9) and connect hose

assembly to pipe to tube elbow (8).

2-77

|

||

|

||