| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

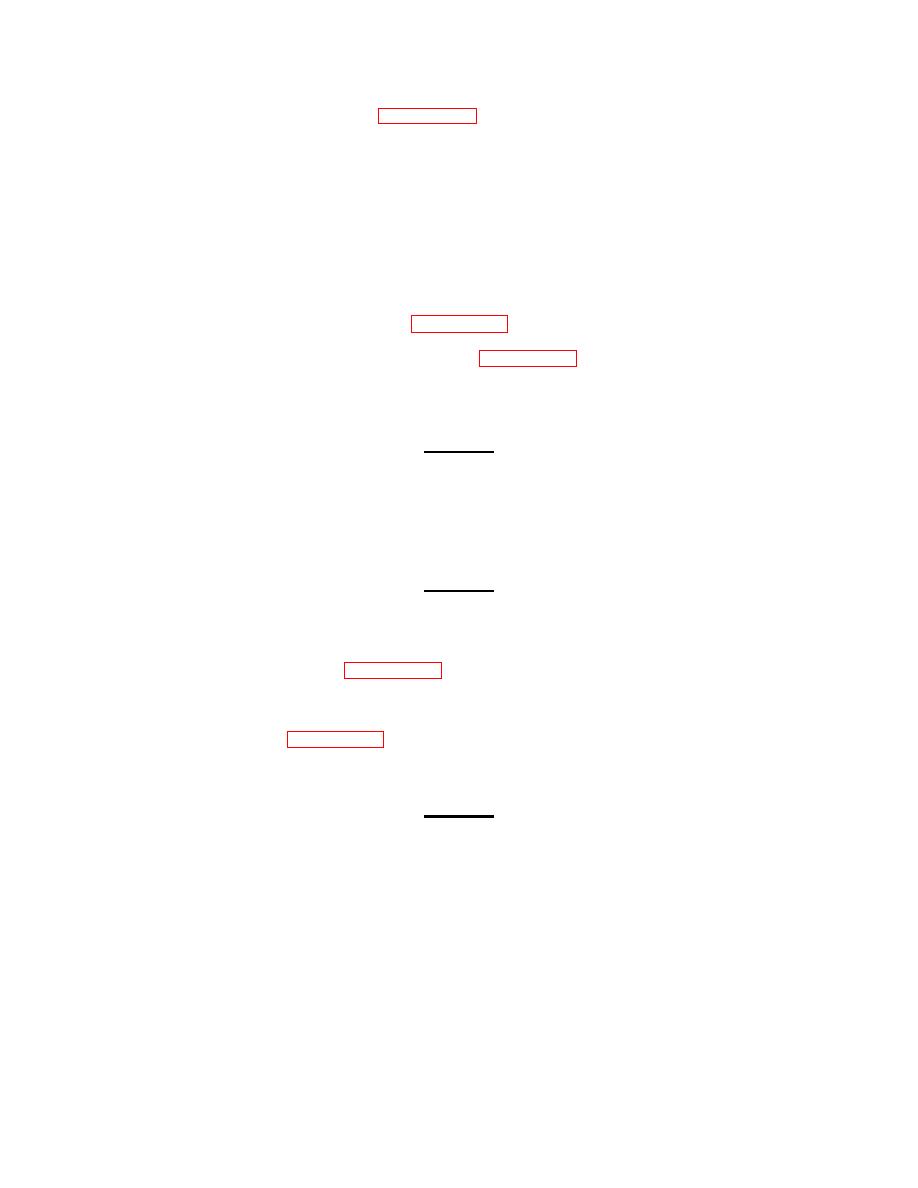

d. Position the ring gaps as shown in FIGURE 3-75.

(1) (Top) Ring (A)

(2) Second Ring (B)

(3) Third Ring (C)

(4) (Bottom) Oil Ring (D)

(5) Piston Pin (E)

e. Install the connecting rod guide pins (1, FIGURE 3-76) .

f. Use piston ring compressor to compress the rings (FIGURE 3-77) .

g. Using the accessory drive pulley, rotate the crankshaft to position the connecting rod journal at "BDC"

(bottom dead center).

CAUTION

To avoid piston damage, do not use a metal object to push the piston in the liner.

NOTE

The tang of the connecting rod must be toward the camshaft side of the cylinder block.

CAUTION

Do not use a hammer or equivalent to install the piston in the cylinder liner. The

piston rings can be damaged.

h. Using piston ring compressor (FIGURE 3-77), install the connecting rod in the cylinder liner, and push

the piston down. If the piston does not move freely, remove the piston. Inspect for broken or

damaged rings.

i. Use the guide pins (1, FIGURE 3-76) to pull the connecting rod (2) against the crankshaft.

j. Remove the guide pins (1).

CAUTION

The rod cap number must match the number on the connecting rod and must be

installed with the numbers aligned to prevent damage to the connecting rods and

the crankshaft. The slot in the cap and the rod must be toward the camshaft

side of the cylinder block.

NOTE

The tang of the bearing must be in the slot of the cap.

3-116

|

||

|

||