| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

(e) Record the indicator reading at three different points: 3 o'clock, 6 o'clock, and 9 o'clock.

(f) Continue rotating the crankshaft until the dial indicator is at the 12 o'clock position.

(g) Check the dial indicator to make sure the needle still points to "O" (zero).

NOTE

If the dial indicator is not pointing to "O" (zero), check the tightness of the

indicator arm and repeat steps (a) through (g) above.

(h) Determine the total indicator run out (TIR) as follows:

mm

in

Example:

12 o'clock

( 0.00)

0.00

3 o'clock

(+ 0.08)

+ 0.003

6 o'clock

(- 0.05)

- 0.002

9 o'clock

(+ 0.08)

+ 0.003

Equals TIR

( 0.13)

0.005

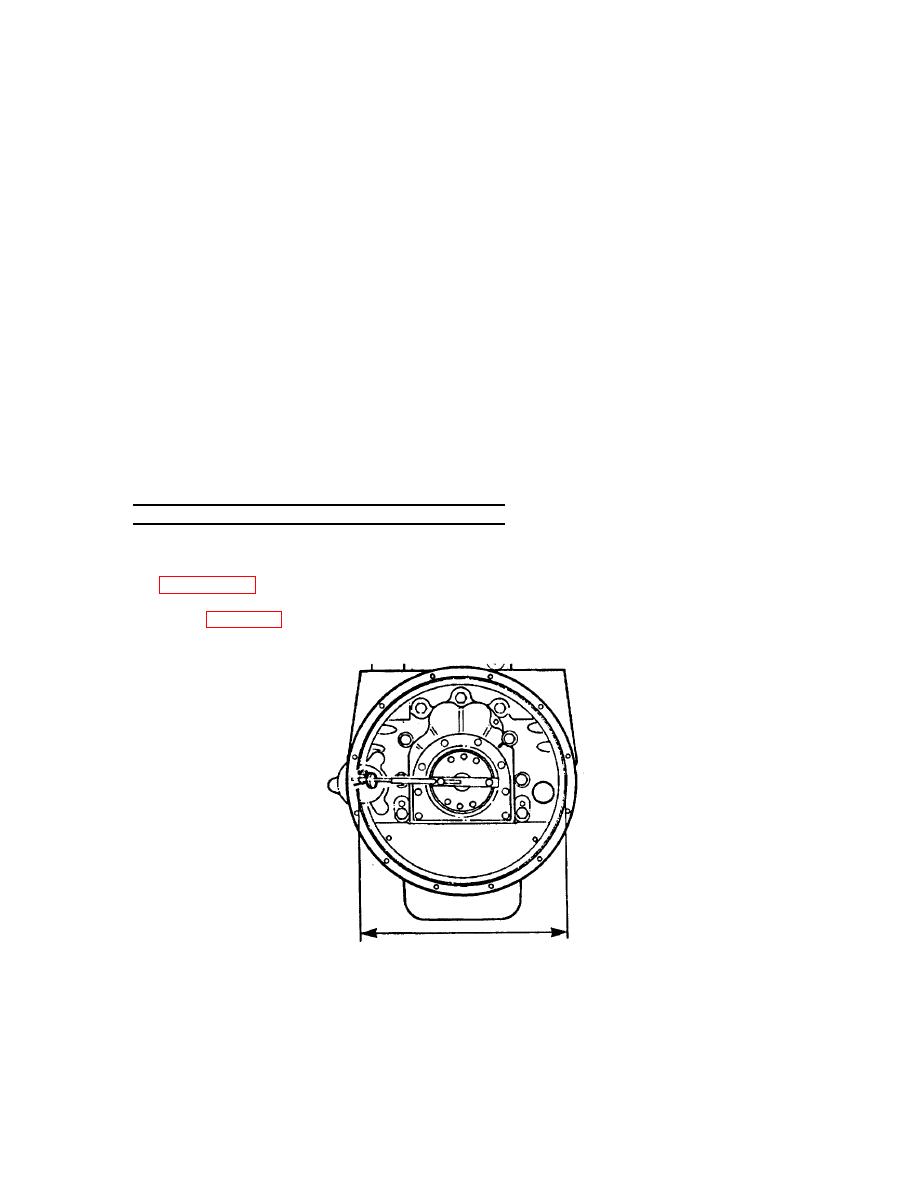

(i) The maximum allowable total indicator reading (TIR) depends on the diameter of the housing bore

(j) Refer to Table 3-10 for allowable total indicator reading (TIR).

FIGURE 3-91. Housing Bore Diameter.

3-130

|

||

|

||