| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

NOTE

On PTO units which have been disassembled, steps (a)

through (i) of the Assembly Procedures must be

accomplished in order to reach a starting point for

bearing adjustment on the SP 111 HP2 (steps (a) through

(g) on the SP 214 P1, paragraph 4-15).

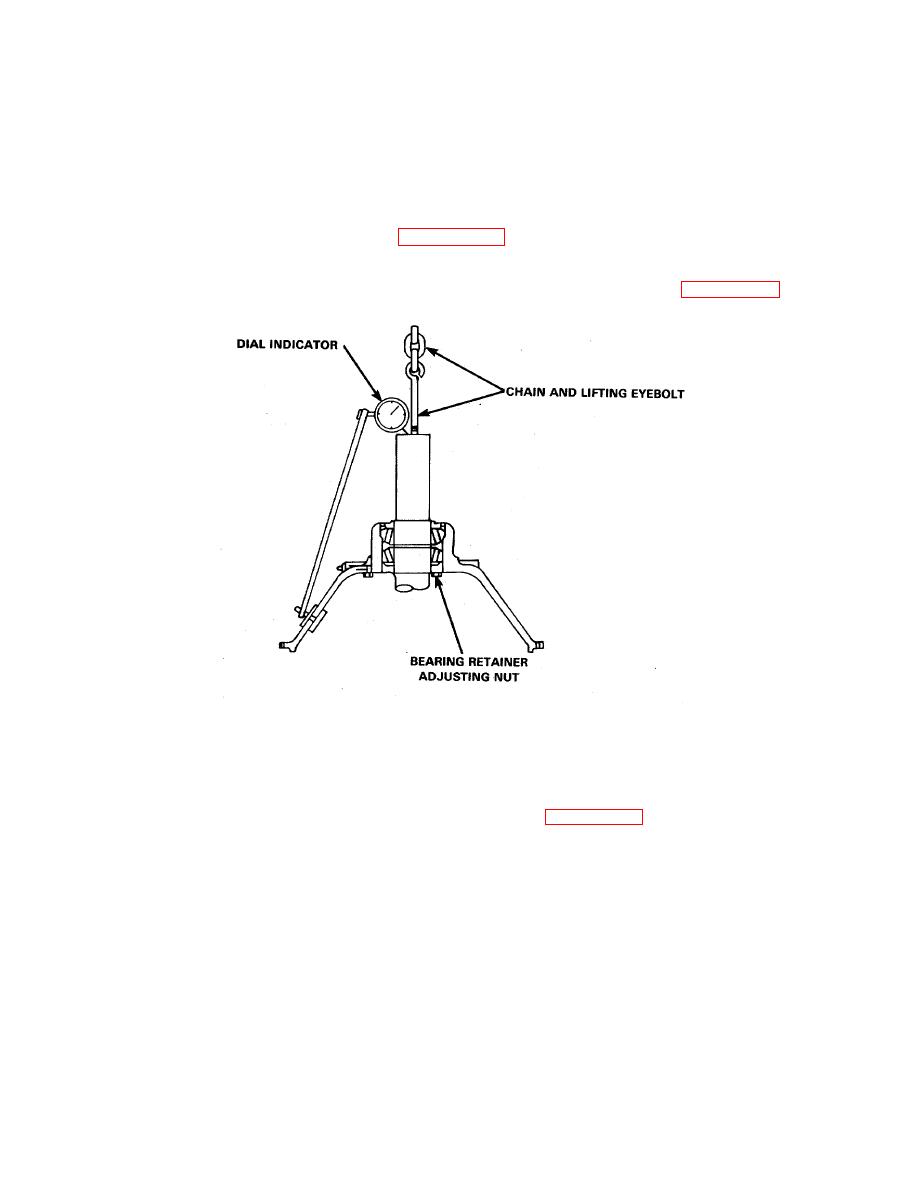

(1) Use the bearing retainer nut for adjusting the tapered roller bearings. Refer to FIGURE 4-22.

FIGURE 4-22. Adjusting Roller Bearings.

(a) Tighten the retainer nut until the shaft requires 60 in-lb. of force to turn.

(b) Back off the retainer nut 3-1/4-4-1/4 notches. See FIGURE 4-23.

(2) Dial indicate the end play as follows:

(a) Set PTO on supporting blocks with the clutch shaft in a vertical position with the input end

down.

(b) Attach an eyebolt in the 1/4 PTF thread at the output end of the shaft. (Models which do not

have this hole will have to be inverted with the input end up, and clearance-at the output end

below, for dial indicator mounting. An extra hub nut with a loop shaped strap welded to it car

be used to apply the pushing and pulling forces required-during end play check.) See

FIGURE 4-18.

4-46

|

||

|

||