| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

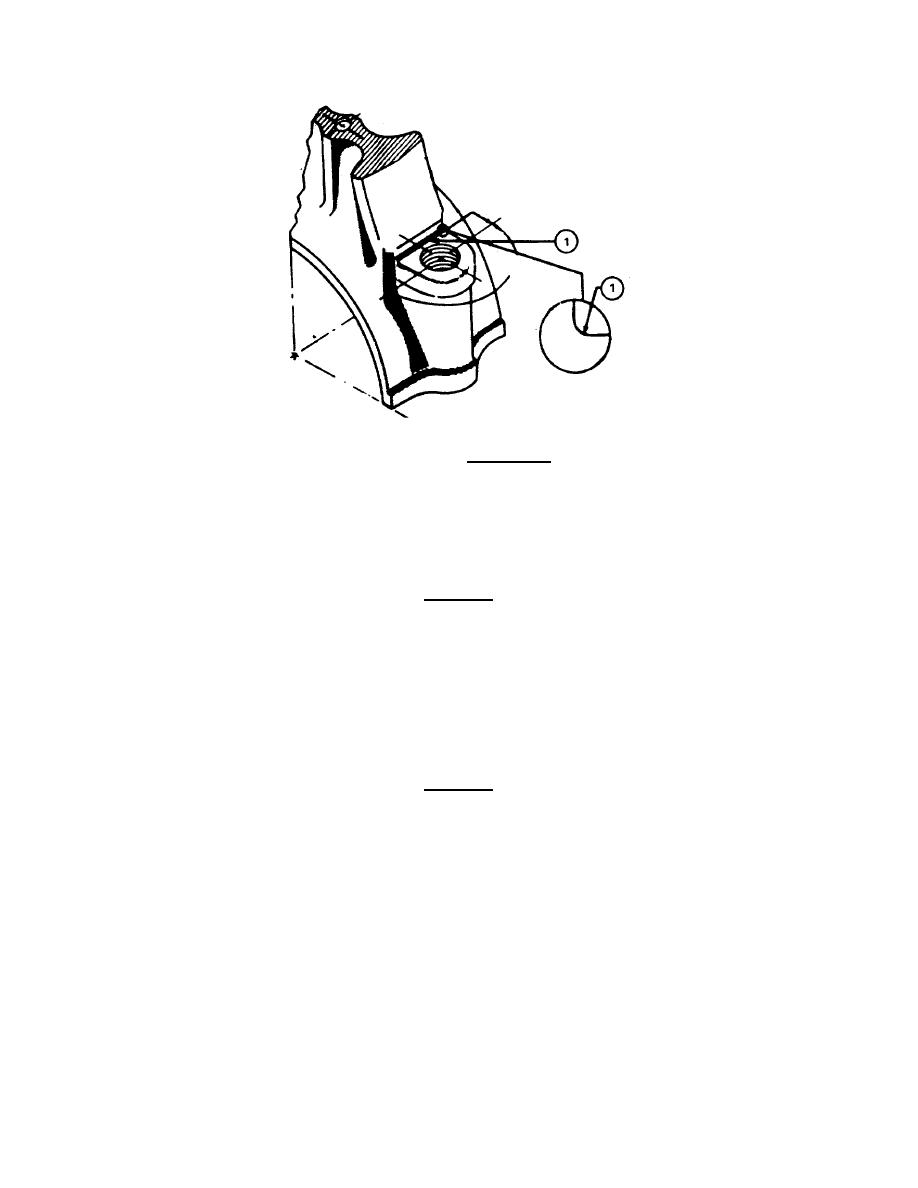

FIGURE 4-35. Fillet Radius.

(b)

A maximum of 0.0625 inch (1.587 mm) material can be cut from the pad to repair the radius.

(c)

Remove any sharp edges from the pad.

c.

Clean and inspect the pistons.

CAUTION

To avoid damage to the pistons, make sure the cleaning solvent

is approved for aluminum. Refer to Federal Specification PD-

680.

(1)

Allow the piston to soak for a minimum of 30 minutes in a tank containing an approved cleaning

solvent for aluminum.

(2)

Use a hot, soapy solution and a nonmetallic brush to remove carbon deposits.

CAUTION

Do not use a metal brush. A metal brush will damage the piston ring

grooves. Do not use glass beads to clean the grooves. Walnut shell

blasting may be used on grooves with a ni-resist insert and on the

dome of the piston.

Use the minimum effective pressure and do not concentrate

the spray in one area for an extended period of time.

Do not use walnut shell blasting on the pin bores or aluminum

grooves. This can damage pin bore surface finish or prevent the

rings from seating correctly in the grooves.

4-72

|

||

|

||