| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-SDC

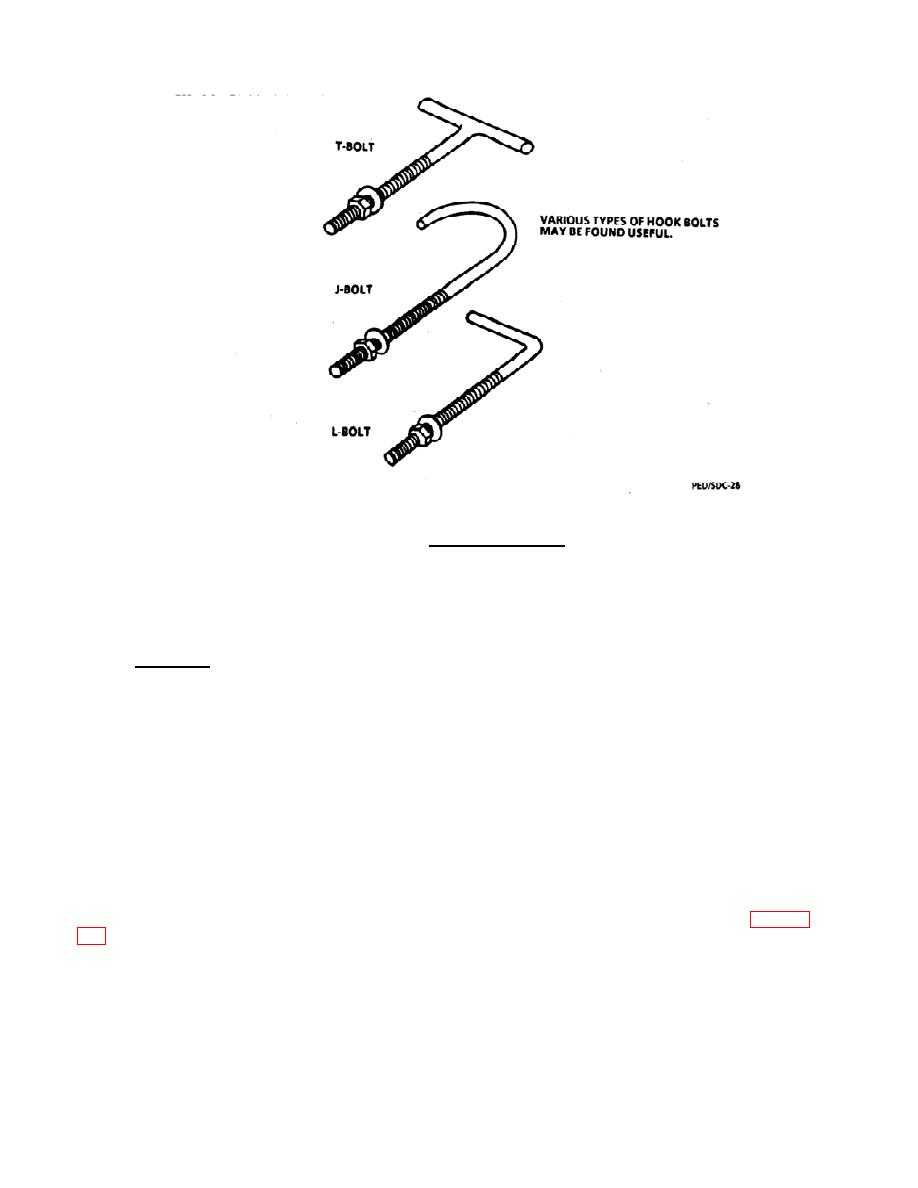

Types of Hook Bolts

ship, which will give an inside patch. Nuts and washers are provided for holding and tightening the patch. It

might be well to put large wings on the nuts.

Section IV. QUICK-SEALING LEAKS AND CRACKS

8-10. METHODS. Quick action in sealing leaks and cracks can prevent further flooding or even advance

the flooding boundary back to the area of damage. The following paragraphs describe a number of methods

for sealing leaks and cracks.

a.

Crack in steel plate. A fairly common type of leak is caused by a crack in a steel plate. When the

leak is in a flat surface away from frames and other interferences, generally it can be stopped by scraping the

surface smooth and applying a patch of sheet packing backed by a shole which can be held in place with

shoring.

b.

Crack adjacent to frame. When the crack is adjacent to a frame, it may be necessary to use

oakum held in place by the corner of a timber. Advantage should be taken of adjacent framing to use clamps

for holding the stopper in place.

c.

Torn plating. Upon reinspecting a crack, it may be found that it has increased in length. The

plating is being torn like paper. To prevent further cracking, drill quarter-inch holes at the extreme ends of the

crack, and plug the holes. If there is time, weld a plate over the crack. This technique is illustrated in FIGURE

d.

Caulking thin plating. Generally, it is not advisable to drive wedges into cracks in thin plating,

especially hardwood wedges, as the wedges tend to open the cracks. Marline, oakum, and rags often can be

used as effective caulking materials.

|

||

|

||