| Tweet |

Custom Search

|

|

|

||

TM 55-1905-242-14

OPERATOR, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE

FOR LANDING CRAFT, MECHANIZED (LCM-8) (ALL VESSELS WITH MOD 2 APPLICATION)

THEORY OF OPERATION

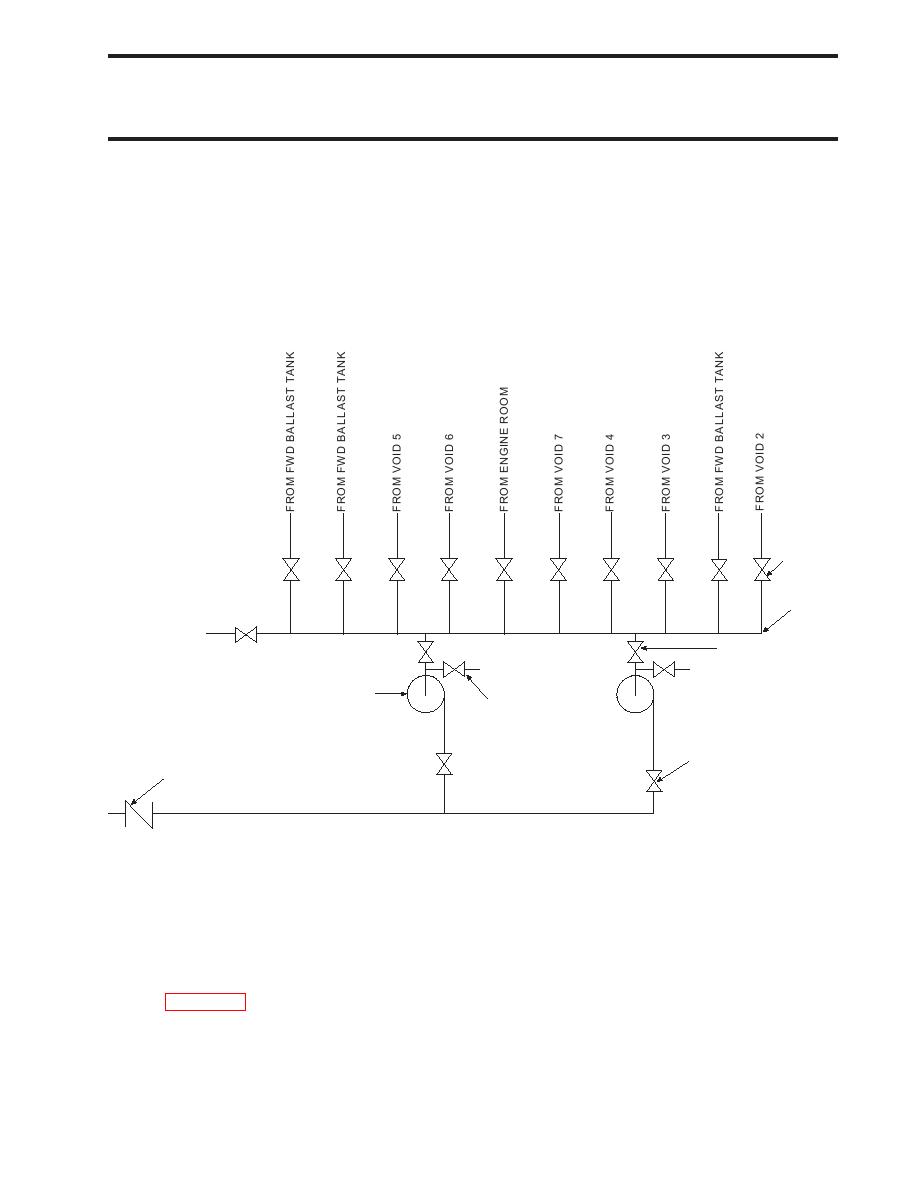

BILGE, OILY WATER, AND FIRE PUMP SYSTEMS

BILGE PUMPING SYSTEM

General

The bilge system provides the primary means for removing water from the watertight voids and spaces when flooding is

imminent aboard the LCM-8 Mod 2. Each watertight compartment aboard the LCM-8 Mod 2 has at least one bilge pump

suction point. The system consists of two hydraulically-driven bilge pumps, a bilge manifold, discharge valves, compart-

ment suction valves, pump suction valves, swing check valve, bilge strainers, and priming connectors. Discharge for this

system is directly overboard through the port side hull, aft of bulkhead 31.

COMPART-

MENT

SUCTION

VALVE

(TYP)

BILGE

MANIFOLD

TO OILY

WATER

PUMP

DISCHARGE

SUCTION

PUMP

VALVE (P/S)

BILGE PUMP (P/S)

PRIMING

CONNECTOR

(P/S)

PUMP DISCHARGE

VALVE (P/S)

SWING CHECK

VALVE

BILGE PUMPING SCHEMATIC

Bilge Pump

Two hydraulically-driven centrifugal bilge pumps, one port and one starboard, provide emergency bilge pumping capability

for the LCM-8 Mod 2. Both pumps are located in the engine room at frame 32 port and starboard of centerline. The pumps

are powered by hydraulic pumps contained in the bilge/ramp/crane hydraulic system. Operation of this hydraulic system is

detailed in WP 0006 00.

Bilge Manifold

A single bilge manifold, located aft of bulkhead 31 centerline, is used to connect the bilge pumps with the various bilge

strainers. By properly aligning the valves at the bilge manifold, the operator can pump bilge from any of the watertight

compartments.

0007 00-1

|

||

|

||