| Tweet |

Custom Search

|

|

|

||

TM 55-1905-242-14

OPERATOR MAINTENANCE

FOR LANDING CRAFT, MECHANIZED (LCM-8) (ALL VESSELS WITH MOD 2 APPLICATION)

OPERATOR TROUBLESHOOTING PROCEDURES

24 VDC ELECTRICAL SYSTEM

INITIAL SETUP:

Personnel Required:

References:

One Watercraft Engineer, 88L

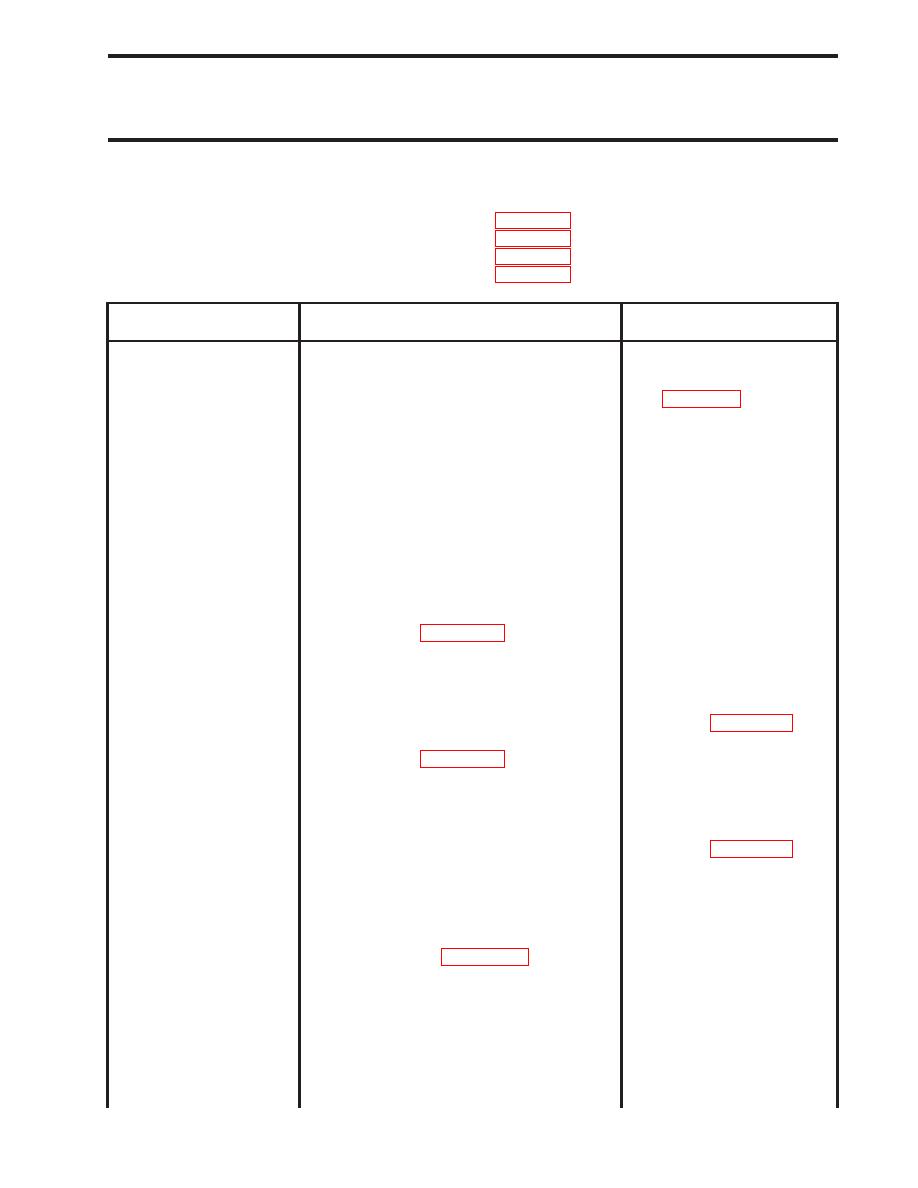

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Alternator not charging.

1.

Check to see if the drive belts are loose or

1.

If drive belts are loose,

broken.

tighten as necessary

2.

If drive belts are broken, no

tify unit maintenance for

replacement.

2.

Check alternator wiring for security and

1.

If alternator wiring is loose,

obvious damage.

tighten wiring.

2.

If alternator wiring is damaged,

notify unit maintenance

for repair.

3.

Test alternator (WP 0060 00).

If alternator is defective,

notify unit maintenance for

replacement.

2. Alternator output low or

1.

Check to see if drive belts are loose.

If drive belts are loose, tighten

unsteady.

as necessary (WP 0060 00).

2.

Test alternator (WP 0060 00).

If alternator is defective,

notify unit maintenance for

replacement.

3. Alternator noisy.

1.

Check to see if drive belts are loose.

If drive belts are loose, tighten

as necessary (WP 0060 00).

2.

Check for misaligned belts/pulleys.

If belts/pulleys are mis-

aligned, notify unit mainten-

ance for repair.

3.

Loosen drive belts (WP 0060 00) and spin

If bearings are noisy or rough,

alternator drive pulley by hand, listening for

notify unit maintenance for

noise and feeling for roughness in bearings.

alternator replacement.

0033 00-1

|

||

|

||