| Tweet |

Custom Search

|

|

|

||

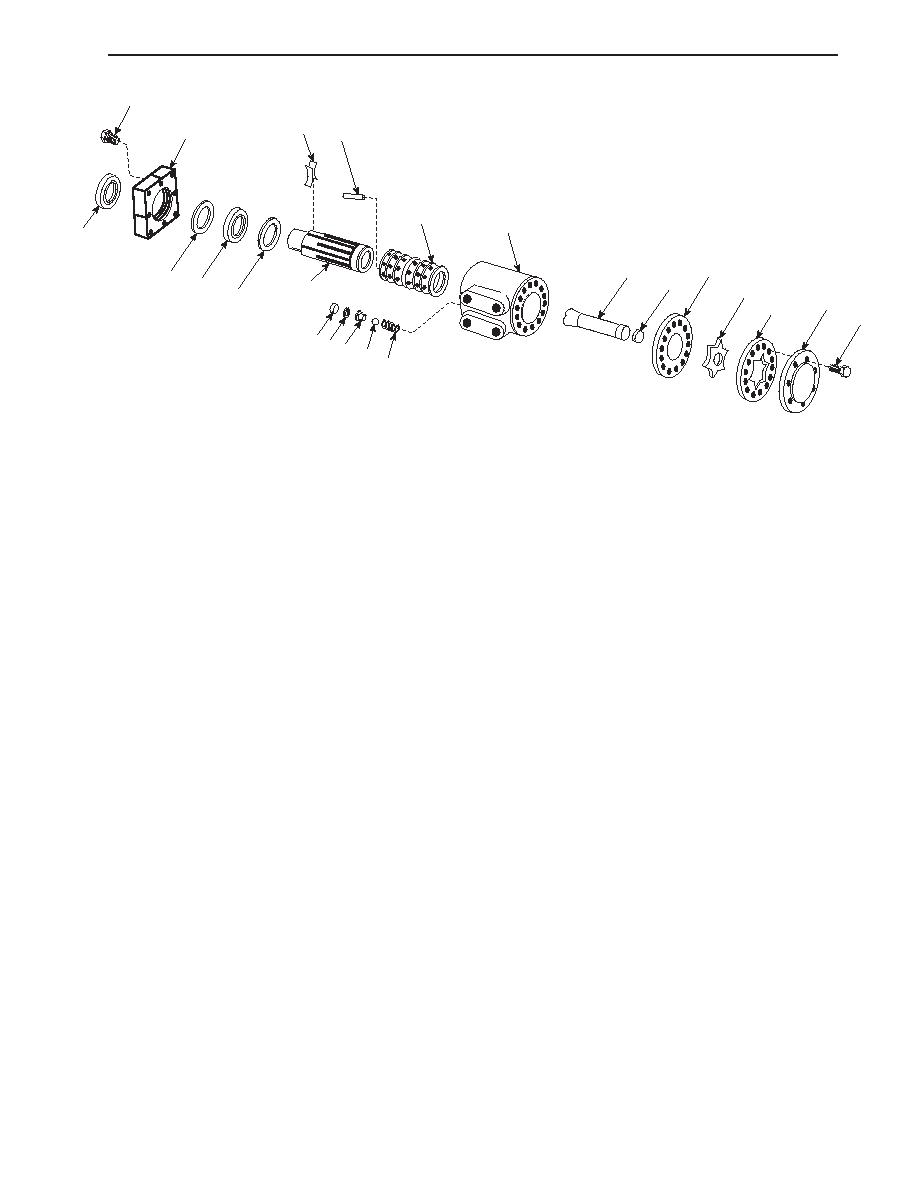

TM 55-1905-242-14

0208 00

8

17

9

18

16

14

10

29

30

11

13

26

15

28

12

25

27

24

19 20

21 22

23

CLEANING

1.

Don protective gloves and goggles.

2.

Clean all metal parts in cleaning solvent and dry with clean wiping rags.

INSPECTION

1.

Inspect the retaining rings and bearings for damage.

2.

Check springs for loss of tension.

3.

Inspect the splines on the control spool for nicks and burrs. Polish small defects. Replace the control spool if the defects

are more major.

4.

Inspect all threaded parts for thread damage.

5.

Inspect the end cap for cracks or other damage.

6.

Inspect the meter gear, star gear, and plate for cracks, burrs, wear, or other damage.

7.

Inspect the spacer and drive shaft for cracks, burrs, wear, or other damage.

8.

Discard all O-rings, packing, and seals and replace with new.

ASSEMBLY--CONTROL SECTION

1.

Position the housing (14) in a vise with the control end up.

2.

Install the check valve compression spring (23) in the housing (14) with the large end first.

3.

Drop the ball (22) into the check valve hole and ensure that it rests on top of the small end of the check valve compression

spring (23).

4.

Thread the check valve seat (21) into the housing (14).

5.

Install the packing (20) on the seal plug (19) and install the seal plug into the housing (14).

0208 00-3

|

||

|

||