| Tweet |

Custom Search

|

|

|

||

TM 55-1915-200-SDC

NOTE

Center the next ply over the preceding one and use the spatula to work out air bubbles and

wrinkles.

e. Position the PVC covering over the plastic patch and press firmly.

f. Position the backup plate over the plastic patch and press firmly.

g. Position the necessary strongbacks and shoring to hold the backup plate in place.

CAUTION

When the temperature around the patch is below 50 F., the careful application of heat from

infrared lamps will speed up the curing of the patch. Excessive heat may make the patch porous

and impair its effectiveness.

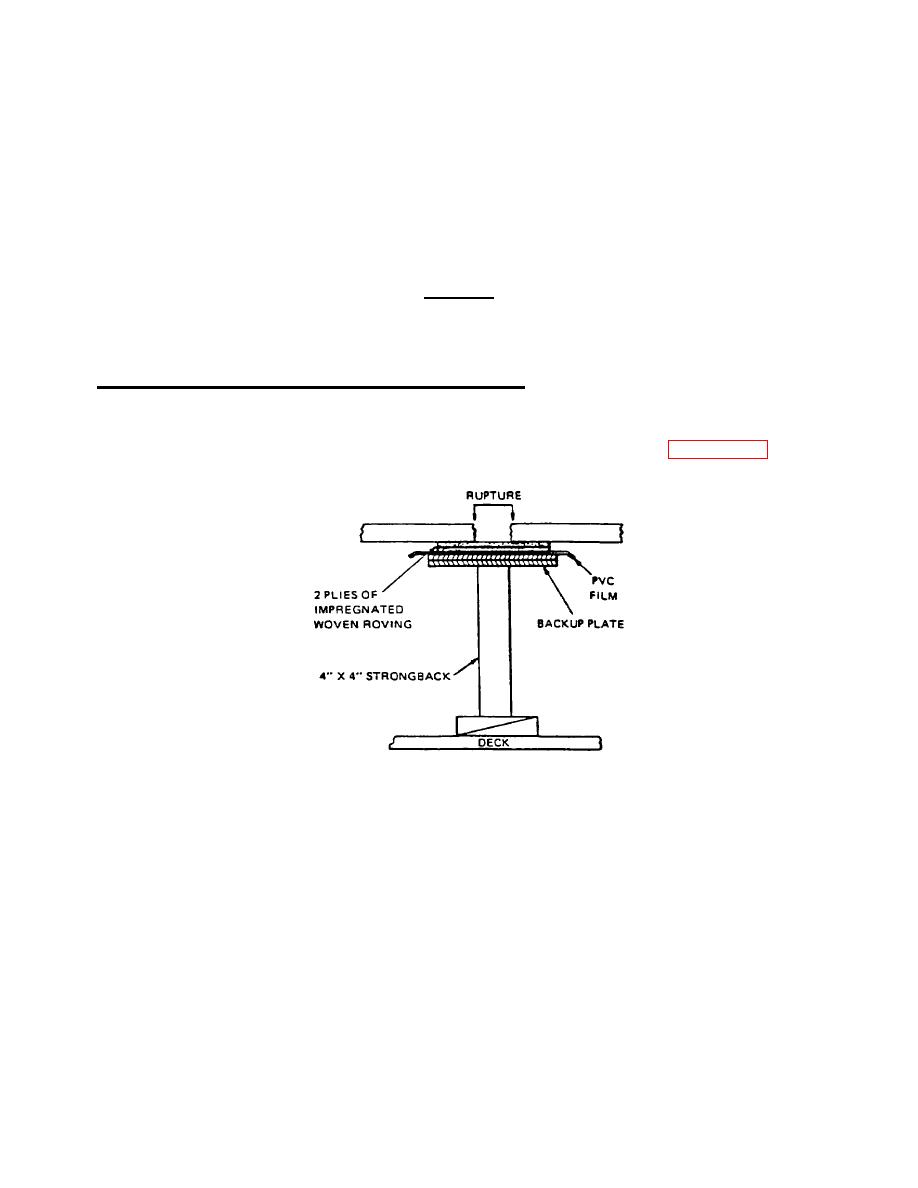

8-22. APPLICATION TO OVERHEAD OR HORIZONTAL SURFACE. In the application of a flat patch to the overhead

or the underside of horizontal flat surfaces, vertical flat surfaces must be prepared with additional precaution taken to

support the weight of the patching materials as they are being applied. Because of weight, the successive layers of

impregnated (liquid resin hardener) woven roving cloth will have a tendency to pull away from the area to be patched.

For this reason, a minimum of two men should be employed during these operations. FIGURE 8-11 illustrates the

overhead or horizontal flat surface patch.

FIGURE 8-11. Overhead or Horizontal Flat Surface Patch.

8-26

|

||

|

||