| Tweet |

Custom Search

|

|

|

||

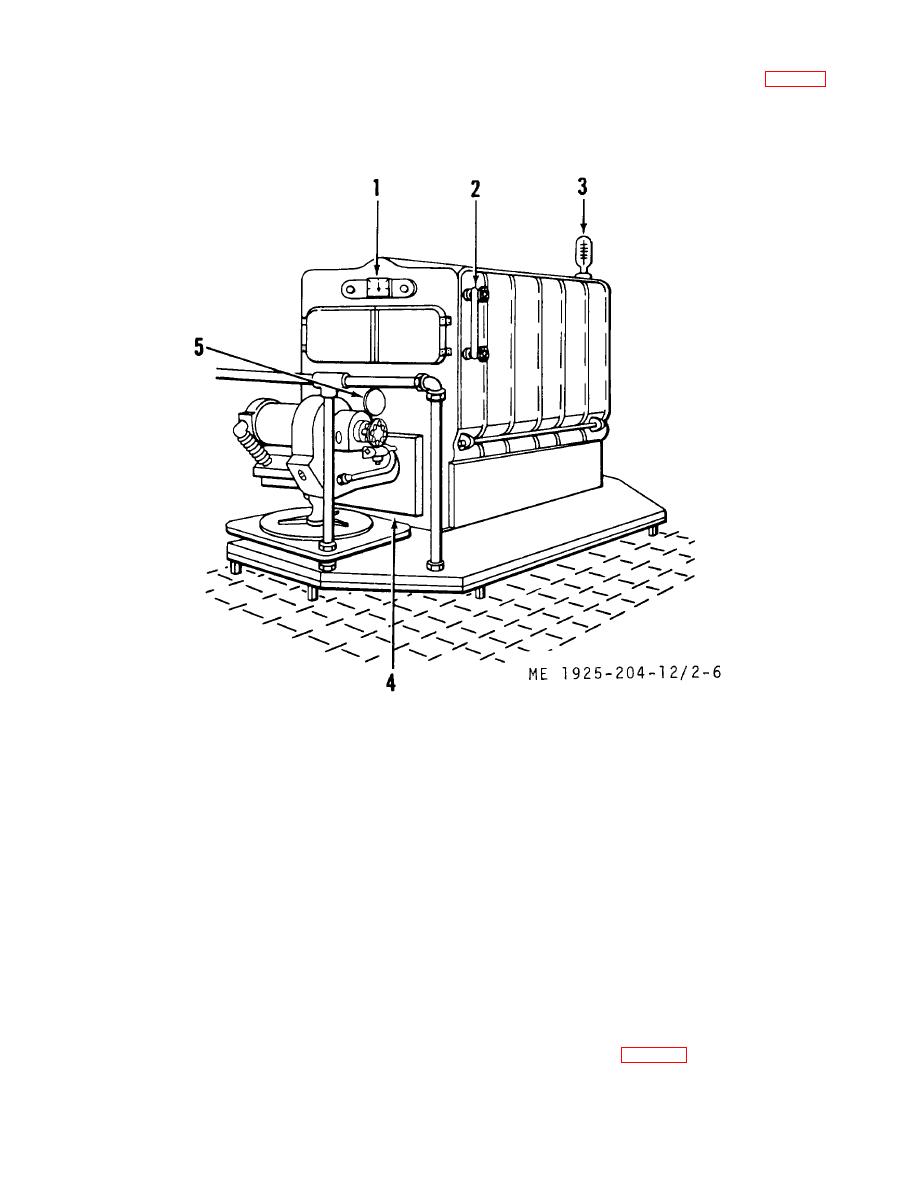

(4) Pressure and vacuum gage (1, fig. 2-6). The

during operation the stack temperature and helix will

cool, thereby closing the cold or starting contacts, and

pressure and vacuum gage is located on front of the

the burner will lock out after the preset time of 90

boiler. The normal pressure reading on this gage should

seconds.

be 5 psi, and should never exceed 10 psi.

1 Pressure and gage

4 Burner unit

2 skater gage

5 Sight glass

3. Pressuretrol

Figure 2-6 Heating boiler controls

(5) Water gage (2). The water gage is located on

(8) Air inlet shutter. The air inlet shutter is located

side of heating unit at top right front. The gage indicates

on side of the burner blower housing. Its purpose is to

actual level of water in the boiler. Unit should be

adjust the amount of air being admitted to unit burner.

secured immediately if water level disappears from the

(9) Oil burner cutout switch. The oil burner cutout

gage. The normal water level is at midpoint in the

switch is located adjacent to the oil burner. This switch

glass.

gives independent control of electric power to the burner

(6) Pressuretrol (3). The pressuretrol is located

unit.

at the top outboard end of the boiler. The function of

(10) Low water cutoff. The low water cutoff is

this control is to secure the boiler heating unit should

located on forward side of boiler. Its purpose is to

pressure exceed 10 psi.

secure the boiler heating unit if water level drops below

(7) Safety valve. The safety valve is located at

the safe operating level.

top of the boiler. Its function is to release the boiler

(11) Heating system control valves. The

pressure when pressure exceeds 10 psi.

location and identification of heating system control

valves are shown in table 2-1 below:

2-11

|

||

|

||