| Tweet |

Custom Search

|

|

|

||

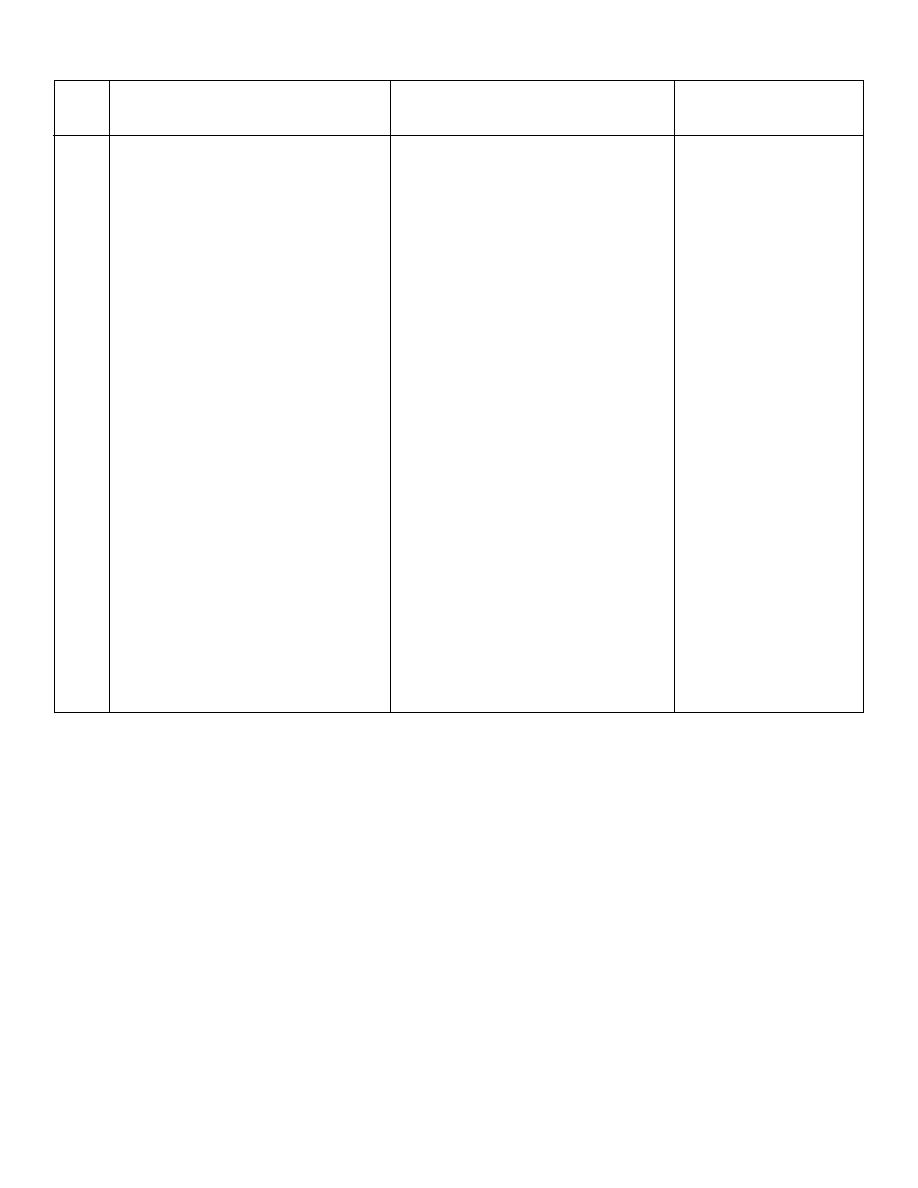

Table 2-2. Compressed Air System Control Valves.

Valve

Service

Location

Label

No.

inscription

1

No. 1 compressor relief valve, set at 265 psi.

Stbd. side, above engineroom floor, frame 20.

2

No. 1 compressor discharge valve.

Stbd. side, above engineroom floor, frame 21.

COMP. OUTLET

3

No. 2 compressor relief valve, set at 265 psi.

Near centerline, above engineroom floor, frame 20.

4

No. 2 compressor discharge valve.

Near centerline, above engineroom floor, frame 21.

COMP. OUTLET

5

No. 2 air tank inlet valve.

Stbd. side, below main deck, frame 21.

AIR TO TANK

6

No. 1 air tank inlet valve.

Stbd. side, below main deck, frame 22.

AIR TO TANK

7

No. 2 air tank drains (2).

Port and stbd. sides below air tank, frame 21.

BLOW OUT

8

No. 2 air tank outlet.

Portside, below main deck, frame 21.

AIR FROM TANK

9

No. 2 air tank to pressure gage.

Portside, below main deck. frame 21.

GAGE BD.

10

No. 1 air tank drains (2).

Port and stbd. sides below air tank, frame 23.

BLOW OUT

11

No.1 air tank outlet.

Portside, below main deck, frame 22.

AIR FROM TANK

12

No. 1 air tank to pressure gage.

Portside, below main deck, frame 23.

GAGE BD.

13

Moisture separator drain valve.

Portside, below main deck, frame 26.

MOIST. DRAIN

14

Air line to gage board.

Near centerline, below main deck. frame 26.

GAGE BD.

15

Air to engine.

Near centerline, below air tank. frame 26.

AIR TO ENG

16

Sea chest blowout branch.

Portside, below engineroom floor, frame 22.

S. C. BLOW

17

Sea chest blowout branch.

Stbd. side. below engineroom floor, frame 27.

S. C. BLOW

18

Sea chest blowout branch.

Portside, below engineroom floor, frame 31

S. C. BLOW

19

Sea chest blowout branch.

Portside, below engineroom floor, frame 25

AIR TO SEA CHESTS

20

Ship's service air hose.

Stbd. side, above engineroom floor, frame 41.

AIR HOSE

21

Ship's service 50 psi air supply.

Portside, at bulkhead, at engineroom floor, frame 26.

50# AIR SUPPLY

22

Outlet from 250-50 psi reducing station.

Portside, above engineroom floor, frame 26.

50 # AIR SHUTOFF

23

Reducing valve for 250-50 psi reducingt station.

Portside, above engineroom floor, frame 26.

24

Strainer drain in 250-50 psi reducing station.

Portside, above engineroom floor, frame 26.

25

Inlet to 250-50 psi reducing station.

Portside. Above engineroom floor, frame 26.

250# TO 50# AIR

26

Bypass for 250-50 psi reducing station.

Portside, above engineroom floor, frame 26.

250#-50# BY-PASS

27

Inlet to 250-100 psi reducing station.

Near centerline. below whistle air tank, frame 30.

250# TO 100# AIR

28

Strainer drain in 250-100 psi reducing station.

Near centerline. below whistle air tank, frame 31.

29

Reducing valve for 250-100 psi reducing station.

Near centerline. below whistle air tank, frame 31.

30

Outlet from 250-100 psi reducing station.

Near centerline, below whistle air tank, frame 31.

100# AIR SHUTOFF

31

Bypass for 250-100 psi reducing station.

Near centerline, below whistle air tank, frame 30.

BY-PASS 250#-100#

32

Inlet to whistle air tank.

Near centerline, at whistle air tank, frame 32.

AIR TO WHISTLE TANK

33

Whistle air tank drain.

Near centerline, below whistle air tank, frame 31.

DRAIN

34

Engineroom air tools.

Portside. At bulkhead, above engineroom floor,

AIRTOOLS

frame 32.

35

Main deck air tools.

Portside. above main deck. frame 32.

AIR TOOLS

36

Whistle tank relief valve set at 110 lb.

Near centerline. at whistle tank. frame 30.

37

Air to whistle.

Near centerline, below main deck, frame 29.

AIR TO WHlISTLE

38

Sea chest blowout branch

Portside, near bulkhead. At engineroom floor,

S C. BLOW

frame 32

2-15

|

||

|

||