| Tweet |

Custom Search

|

|

|

||

TM 55-1925-204-12

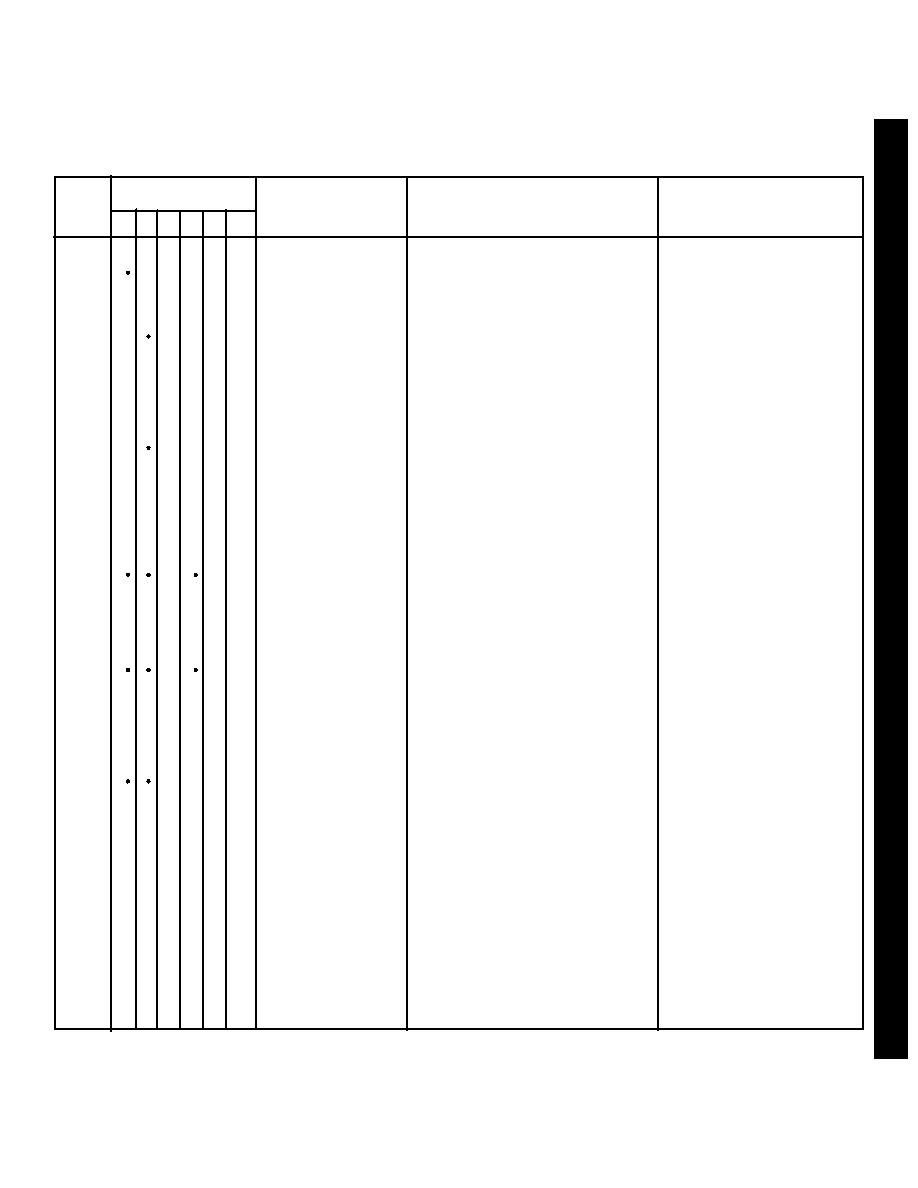

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services

Tug Diesel Large Design 3006

B - Before

A - After

M - Monthly

D - During

B/A - Biannually

Q - Quarterly

Intervals

Item

Item To Be

Procedure

Equipment Will Be Reported

No.

BDA

M Q B/A

Inspected

Not ready/Available If:

1

External hull above

Crew inspect for structural

Watertight integrity or

waterline

damage above waterline

operational capability is

impaired.

2

External hull(below

Crew inspect accessible hull for

Underwater hull is

the waterline). Rud-

flooding. *If crew inspection

damaged/deteriorated to

der, zinc anodes,

reveals hull leakage/flooding,

extent that watertight in-

digital depth

divers inspect underwater hull

tegrity is impaired.

sounder transporter,

for damage.

sea chest strainers

3

Propeller and pro-

Check for misaligned/bent pro-

Propeller/propeller shaft

peller shafts

peller shaft and worn shaft bear-

and/or shaft (cutlass)

ing. Stand on stern of vessel while

bearing are damaged/ex-

running free. Should the vibra-

cessively worn.

tion be above normal, propeller

shaft shall be inspected by

divers.

4

Anchor windlass

Inspect for proper operation in

Vessel has to use anchors.

speeds ahead and astern. Check

oil reservoir to level plug.

Lubricate IAW LO55-3950-205-

12 and 55-3950-209-12.

5

Stern capstan

Inspect for proper operation in all

speeds ahead and astern. Check

oil level monthly. Maintain level

to filler plug (10 gal capacity).

Lubricate IAW LO55-3950-204-

12.

6

Steering system and

Inspect steering rams through in-

Rudder does not res-

rams

spection cover for excessive leak

pond to wheel house

off from ram packing glands.

control. No fluid in

Check packing glands for proper

sight glass. Mechani-

torque and adequate seal. Check

cal stops improperly

steering motor for arcing and

set. Steering motor

overheating by visual and touch

draws excessive amps

inspection. Check reservoir for

and overheats. Emer-

proper level of steering fluid

gency steering fails to

OE10/HDO (1/2 full sight glass).

function during

Check directional check valves

routine test.

for leakage and torque on pipe

unions. Ensure mechanical stops

are set properly 35o port and stbd.

Change 1

3-3

|

||

|

||