| Tweet |

Custom Search

|

|

|

||

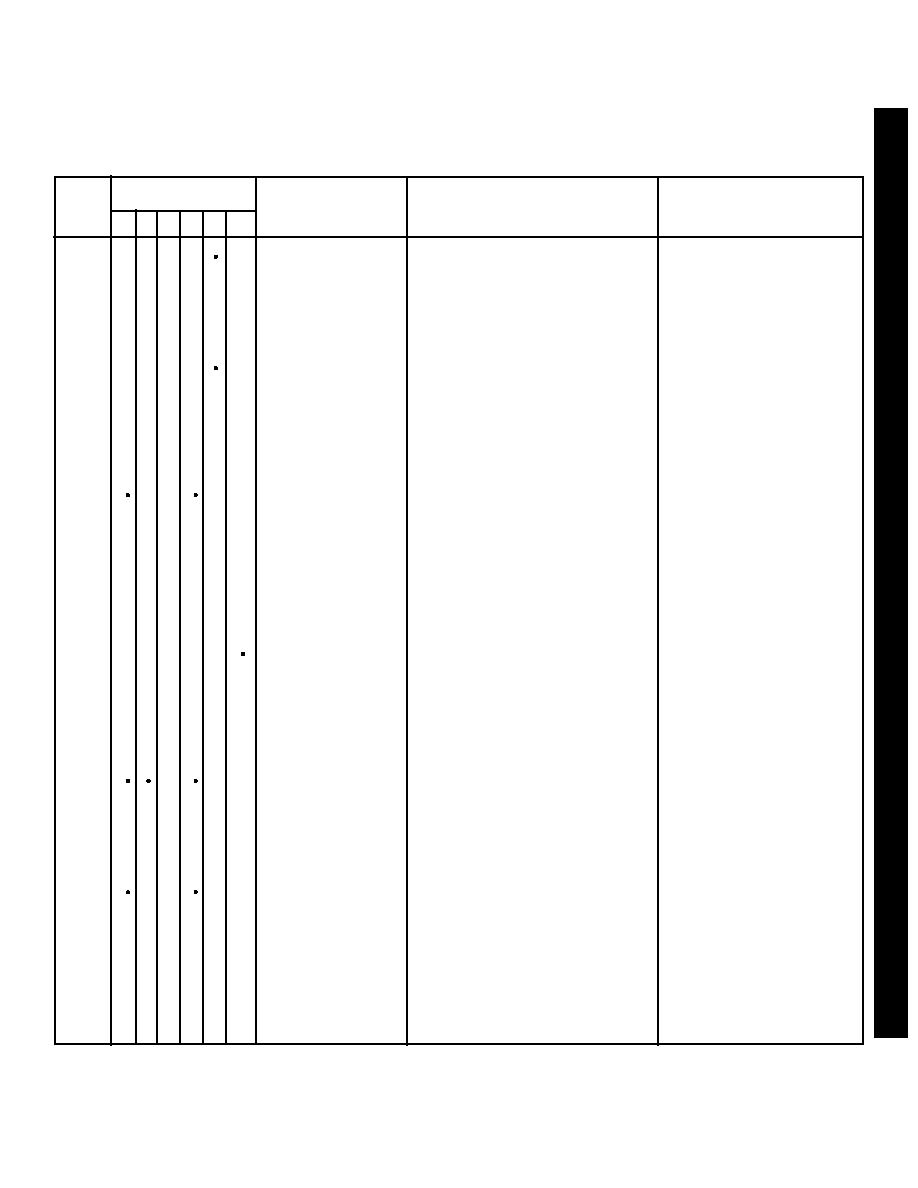

TM 55-1925-204-12

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

Tug Diesel Large Design 3006

B - Before

A - After

M - Monthly

D - During

B/A - Biannually

Q - Quarterly

Intervals

Item

Item To Be

Procedure

Equipment Will Be Reported

No.

BDA

M Q B/A

Inspected

Not ready/Available If:

14

Tank vents

Ensure vents pipes are free from

Vent tube is rup-

corrosion/deterioration. Check

tured/sheared allowing

flame arrestor screen for rust and

S.W. into fuel tank en-

paint. Ensure ball check valves

dangering vessel and

operate correctly - ball free.

crew. Rubber ball is miss-

ing from check valve.

15

Vertical ladders,

Inspect preventer bars for frac-

scupper drains,

tures, check drain pipes for inter-

bulwark, freeing

nal corrosion. Check ladder

ports.

securements and hand rail for

deterioration/corrosion. Ensure

non-skid is applied to ladder

steps.

16

Life raft, life rings,

Inspect for damage to life raft and

Life raft is damaged/

light marker, rail

hydrostatic release. Ensure life

nonoperational.

and mounting

ring marker lights are operative.

brackets.

Ensure hull number/name of

vessel is marked on life ring.

Check brackets for damage,

deterioration and ease of

removal. Check life ring buoy for

sufficient life line.

Life jackets and life

Inspect life jackets for hull

Life jackets are missing,

17

jacket stowage

number, bears missing straps, oil

damaged/deteriorated.

locker.

paint soaks and deterioration.

Life jacket lock will not

Check life jacket locker for mark-

float free/cannot be

ing and deterioration. Ensure

removed upon submerg-

l

locker cover floats free upon

ing.

submerging locker.

18

Cargo lights

Ensure cargo lights are opera-

Cargo lights are in-

tional, check for damaged plug

operative.

and frayed wiring. Ensure lenses

are intact and lights can be

elevated for work on fan tail/lazy

boy area.

19

Stack house

Check the exhaust uptakes for

Uptakes are leaking ex-

condition and mounting. Check

haust fumes creating a

for carbon streaks and other in-

carbon monoxide safety

dications of exhaust leaks.

hazard to crew, and

Tighten the mounting bolts and

operating personnel..

connections. Ensure manifolds

and gaskets are in good condition,

secure and not leaking. Check in-

sulation (main engine and both

Change 1

3-5

|

||

|

||