| Tweet |

Custom Search

|

|

|

||

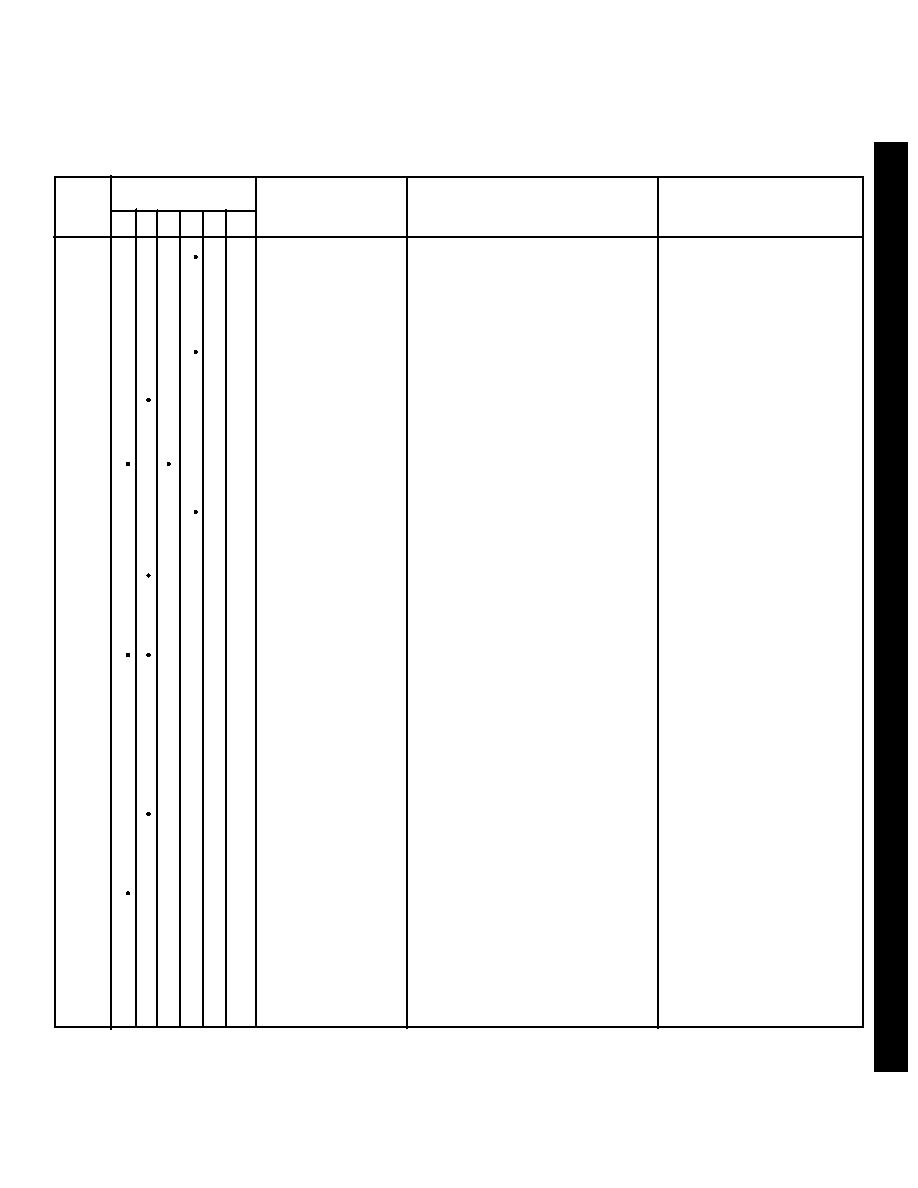

TM 55-1925-204-12

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

Tug Diesel Large Design 3006

B - Before

A - After

M - Monthly

D - During

B/A - Biannually

Q - Quarterly

Intervals

Item

Item To Be

Procedure

Equipment Will Be Reported

No.

BDA

M Q B/A

Inspected

Not ready/Available If:

c. Change intervals

Oil should be changed as a

An oil change directed by

minimum every 200 hrs.

the AOAP is not com-

However, TB43-0210 may justify

pleted, or a change is re-

additional hrs by oil test results.

quired due to dilution or

emulsion.

d. Lubricating oil

Lub-oil filters are changed when

filters

lubricating oil is renewed.

e. Temperature and

Oil pressure gauge installed.

Pressure below 25 PSI.

pressure

Operating pressure at 1450 RPM

30-40 PSI.

f. F.W. expansion

Fill with coolant to within one

Coolant below heat ex-

tank

inch of radiator cap.

changer core.

g. Zinc anode

Inspect and service monthly

renew if deteriorated 50% or

more.

h. F.W. circulating

Check pump for leakage, check

Engine reflects high

pump

temperature for normal opera-

coolant temperature (ex-

tion. Check expansion tank for

ceeds 185 ).

F

loss of coolant and proper circulation.

At 1450 RPM: 160-180oF. Check

i. Coolant

Temperature exceeds

185oF.

temperature

cooling water level and quality of

antifreeze. Refill or replace as

necessary. In winter months

when antifreeze is used make

hydrometer test, and add an-

tifreeze as required. Use ethylene

glycol base antifreeze. Protect to

-32 or as local conditions dictate.

F

j. S.W. circulating

Check for excessive leak off

Engine reflects excessive

pump

temperature of engine. Check im-

high operating tempera-

peller by observing overboard

tures (exceeds 185 ).

F

discharge.

k. S.W. suction and

Remove strainer top with suction

Sea chest is clogged im-

discharge valves.

and discharge valves closed. If

pairing proper engine

SW line strainer

leakage is apparent suction/

cooling.

discharge valve leaks. Check

strainer for foreign objects and

deterioration of strainer basket.

Clean SW strainer and

replace if defective.

Change 1 3-8.1

|

||

|

||