| Tweet |

Custom Search

|

|

|

||

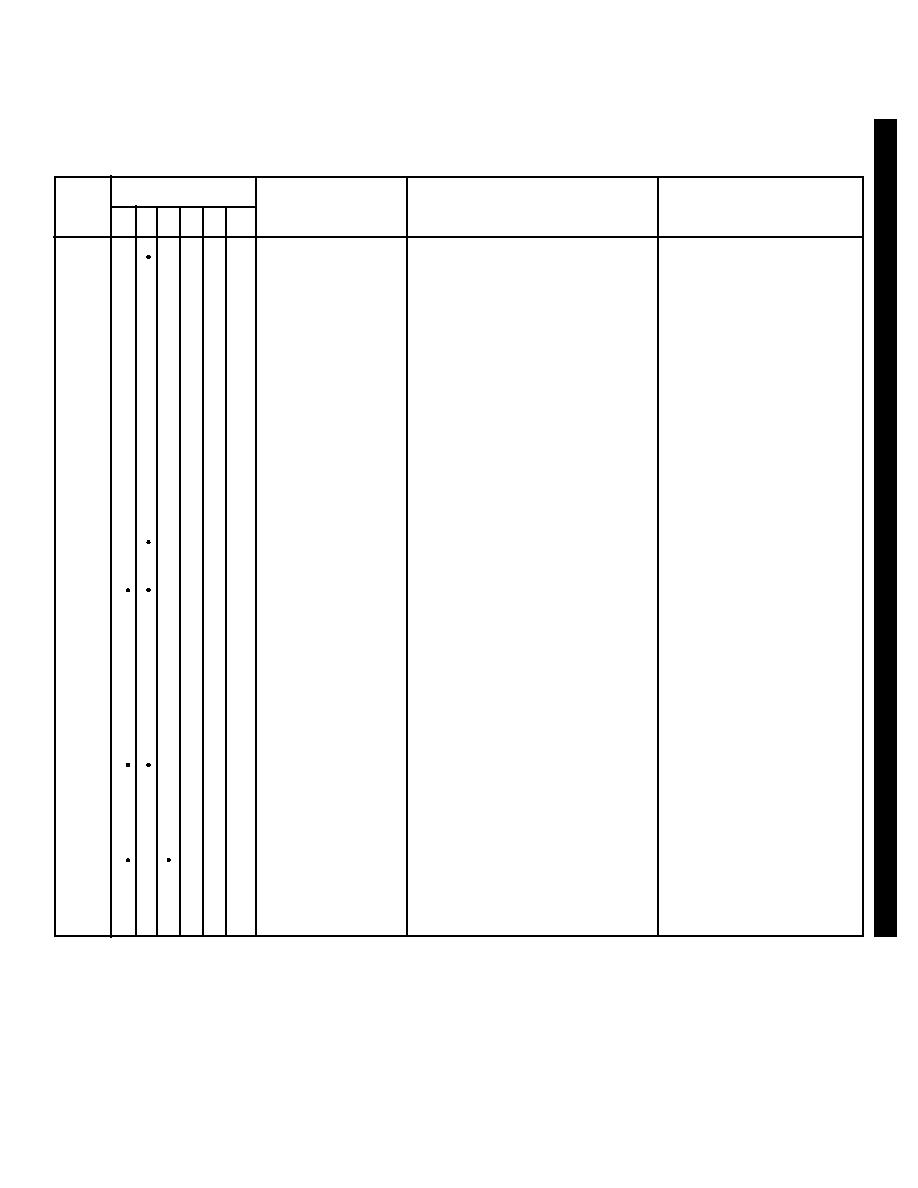

TM 55-1925-204-12

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

Tug Diesel Large Design 3006

B - Before

A - After

M - Monthly

D - During

B/A - Biannually

Q - Quarterly

Intervals

Item

Item To Be

Procedure

Equipment Will Be Reported

No.

BDA

M Q B/A

Inspected

Not ready/Available If:

57

Lazaretted freezers

Start freezer units and observe

No refrigeration available

and galley chill box

bullseye for short charge. Check

for onboard foods.

drive belts for wear, and replace

as one unit. If bubbles are present

in unit bullseye, test unit with halide

torch for leaks. Repair leaks, and

recharge unit. Check operating

pressures with charging manifold for

proper operation. Ensure TXV is

feeding properly. Check seal on

boxes for wear and deterioration.

Ensure box temperatures are lowering

with unit running-hourly check.

Ensure thermometers are in

freezers, and chill box to indicate

operating temperature. Chill box:

o

o

+36- + 42 F. Freezer: 0 to -10 F.

58

Drinking water

Check water temperature Freon-12

fountain

charge and compressor operation.

59

Galley range

Check galley fuel oil day tank for

adequate oil supply. Open stop

valve, and set oil throttle valve to

fire box. Check fire box for oil

presence. Start fire in fire box

with paper. Cut in blower motor

and monitor combustion.

Regulate fire at desired temperature.

Check range, occasionally for proper

operation and overfeeding of oil supply.

Sanitizing sink

Check for proper operatiori and

Sink heater, galley range

60

heater

correct temperature (180-190 ).

F

and the ships boiler are in-

Ensure sink is filled with water

operative.

prior to energizing the heating

element.

61

Battle lantern

Ensure battle lanterns are in good

repair and functional. Check

lantern by dropping electrical load,

and observe lantern for emergency light.

Change 1

3-8.13

|

||

|

||