| Tweet |

Custom Search

|

|

|

||

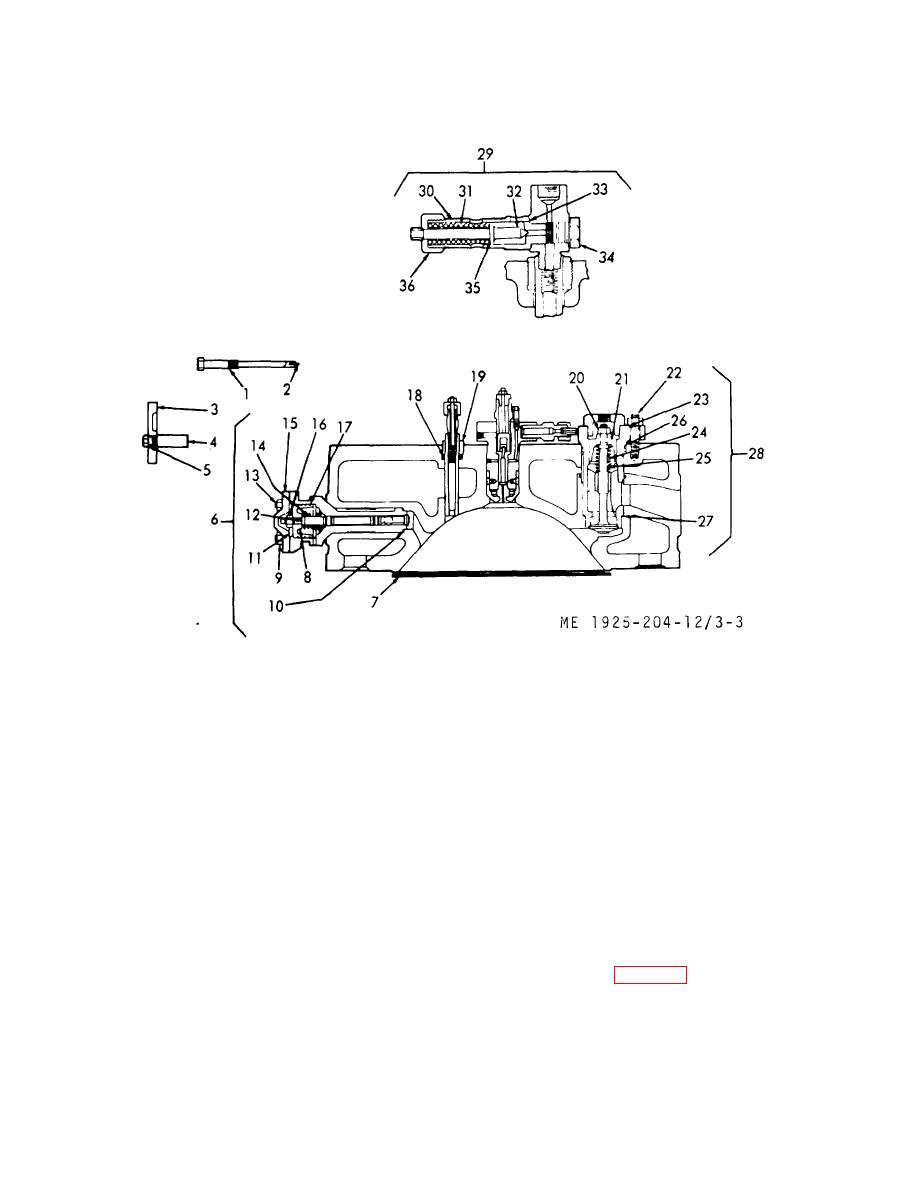

(1) Disassemble by backing off nut (36, fig.

(4) Clean all valve ports, and be sure that all

gasket surfaces are free of particles, ready for

33) and plug (34). Life valve (32), shim (35), and spring

(31) out of cage (30). Remove gasket (33).

installation.

d. Safety Relief Valve.

1.

Holder

13. Stud

25.

Valve

2.

Cartridge

14. Spring

26.

Gasket

3.

Gasket

15. Cover

27.

Gasket

4.

Post

16. Nut

28.

Valve

5.

Gasket

17. Ring

29.

Valve Relief

6.

Valve assembly

18. Packing

30.

Cage

7.

Gasket

19. Packing nut

31.

Spring

8.

Piston

20. Nut, w/cotter pin

32.

Valve

9.

Nut

21. Piston

33.

Gasket

10.

Gasket

22. Stud

34.

Plug

11.

Gasket

23. Gasket

35.

Shim

12.

Valve

24. Spring

36.

Nut

Figure 3-3. Cylinder head valves.

through (3) above. Place in a rack for safe keeping until the

(2) Inspect the spring (31). Replace a broken

cylinder head from which it was removed, is ready for

or weak spring.

installation.

(3) Clean valve (32) in clean fuel oil and wipe

e. Air Starting Check Valve.

dry with a clean cloth. Inspect face of valve for burn, or

(1) Disassemble by removing bushing cotter

bend. Replace a defective valve.

pin and nut (20, fig. 3-3) and lift out piston (21).

NOTE

Remove spring (24), then pull check valve (25) from the

The spring loaded safety relief valve may

cage.

have one or more shims.

When

(2) Clean the air starting check valve in fuel

assembling the valve be sure you can

oil. Wipe dry with a clean lint free cloth. Inspect

use the correct number of shims.

Assemble the spring loaded safety relief

(4)

valve in reverse order of disassembly given in steps (1)

3-23

|

||

|

||