| Tweet |

Custom Search

|

|

|

||

deposit. Remove any ridge with fine

NOTE

emery cloth to prevent ring damage

Use new gaskets at all positions on

when piston is lifted from cylinder

assembly, and remove tags from

bore.

nuts as they are installed on same

studs from which removed.

(1)

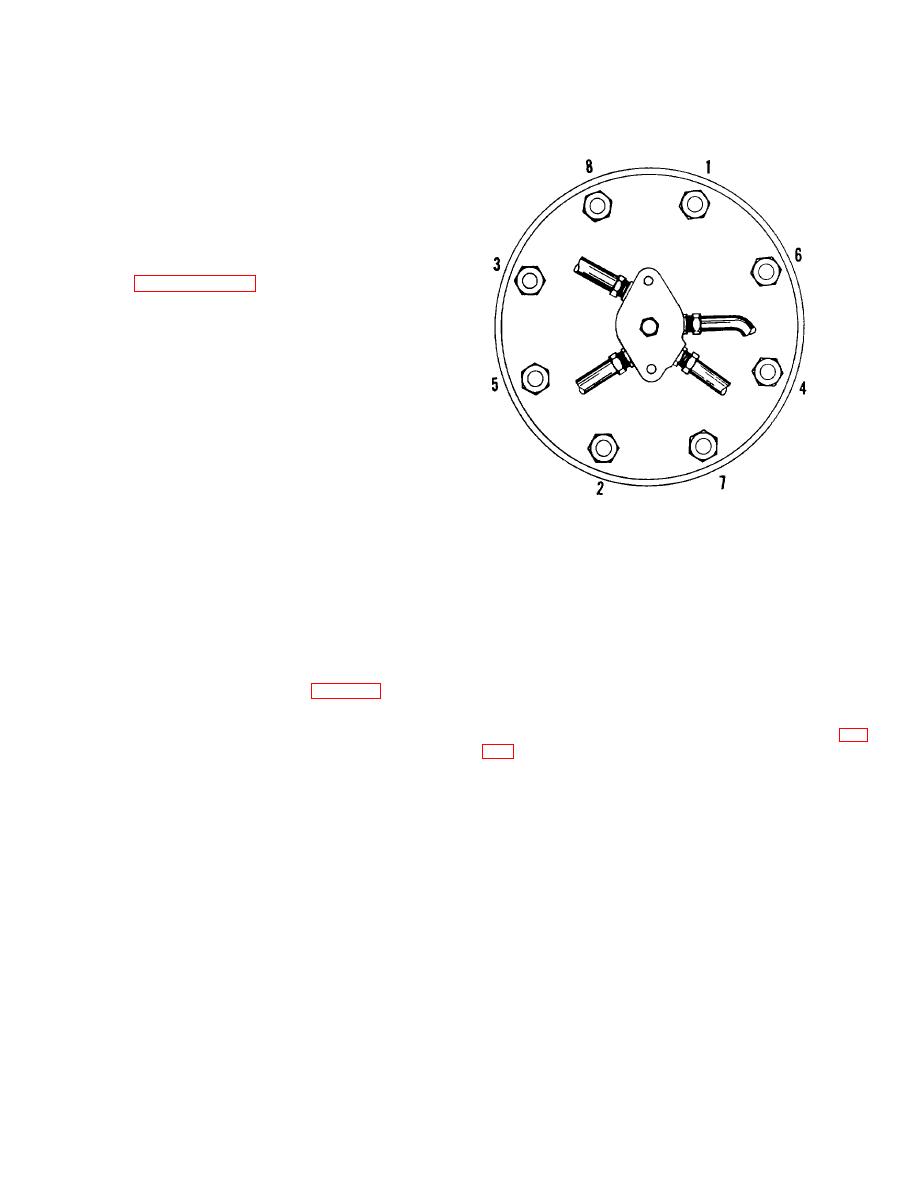

Install head stud nuts hand tight, then torque

to 100 ft. lbs. Inspect nuts for an even drawdown. If

drawdown has been satisfactory, retorque (in same sequence)

to 800-940 ft. lbs.

(2)

Retighten stud nuts at end of 100 hours of

operation.

NOTE

See paragraph 3-12 for fuel injector

repair, removal, and installation

instructions.

3-7. Piston, Connecting Rod, Bearings, Rings, and

Cylinder Sleeve

a. General. The piston is of the trunk type, oil

cooled, and fitted with five piston rings. The connecting

rod is of forged steel and is fitted to the piston by a pin

and sleeve bearing. It is fitted to the crankshaft by a

box type bearing assembly. The bearings are babbitt

type inserts. The cap and box (bearing shells) are not

interchangeable.

When one requires replacement,

Figure 3-5. Sequence of applying torque to

replace both.

holddone nuts..

b. Piston, Connecting Rod, and Rings.

(3)

Use the flywheel ratcheting device to turn

NOTE

engine over until the desired piston is at top dead center.

When a cylinder head is being

(4)

Disconnect the cylinder oil baffle by

removed for access to the piston

unscrewing the capscrew securing the cooling oil stationary

group, do not remove fuel injector or

pipe flange to the outlet pocket, and the nuts at the opposite

valves from the cylinder head.

side of the baffle. The foot of the rod will now go through the

Disconnect and cover line ends and

baffle opening. Remove the baffle by spreading it at the split

section until it will clear the rod.

ports only, to prevent contamination.

(5)

Install the two 3/4 in. eyebolts in tapped holes

(1)

Remove the cylinder head (para. 3-6).

provided in piston. Connect sling to eyebolts and a hoisting

(2)

Remove the crankcase inspection plates from

device, then take up slack.

both sides of the upper base, for the appropriate cylinder.

(6)

Remove two cotterpins and two nuts (9, fig.

NOTE

After the cylinder head is removed,

inspect the counterbore at top of

cylinder for a ridge of carbon

3-25

|

||

|

||