| Tweet |

Custom Search

|

|

|

||

TM 55-1925-204-12

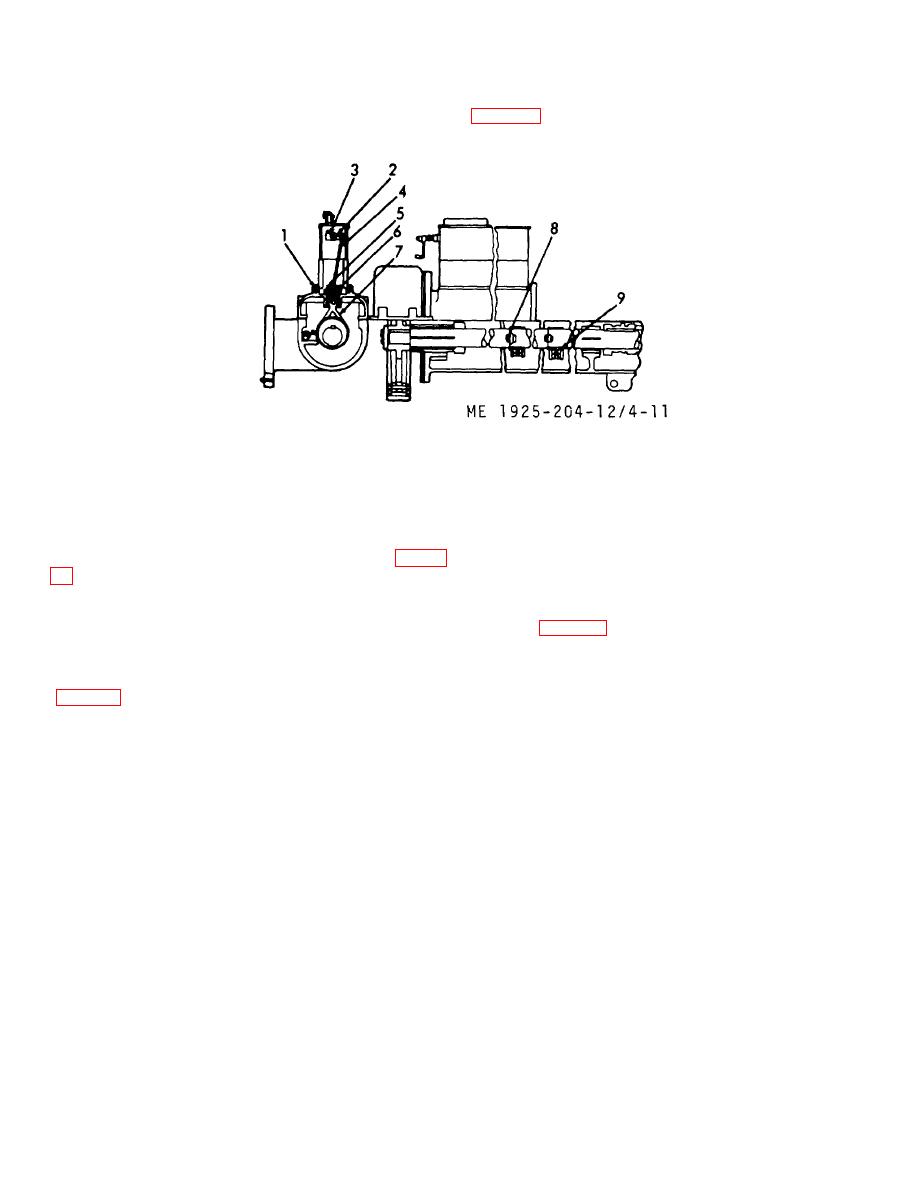

(b) Remove the cover mounting screws;

(c) Disconnect the lubricator drive link (4,

lift cover off the housing, then carefully remove the

gasket. Save for reuse at installation.

1.

Gasket

6.

Crosshead

2.

Arm

7.

Strap

3.

Pin

8.

Bolt

4.

Link, lubricator drive

9.

Key

5.

Sleeve

Figure 4-11. Lubricator drive.

(b) Use clean fuel oil and wash the

interior of the lubricator, then blow dry with ships service

air. Do not turn hand crank while washing the reservoir.

camshaft housing, and move it to a workbench.

(c) Drive the split end taper pin out of the

(2) Disassembly. Under normal conditions,

collar (8, fig. 4-12). Then loosen the shaft bearings at

disassembly for repair is infrequent, but when the

each end of reservoir by backing off the locknut at each

pumping unit (s) cannot be adjusted to the correct

bearing.

discharge rate, proceed as follows:

(a) Move container under the drain cock

the reservoir.

4-21

|

||

|

||