| Tweet |

Custom Search

|

|

|

||

(s) Install all removed accessories (para 5-

2).

(t) Fill the lubricating system (LO 55-1925-

204-12-5).

(u) Fill the engine cooling system.

5-9. Cylinder Block (Crankcase)

a. General. The cylinder block is an integral casting

forming the primary structural part of the engine. Transverse

members provide rigidity and strength, and ensure alignment

of the block bores and bearings under load. The cylinder

block is of cast iron, with water jackets extending the full

length of the bores, but divided into upper and lower sections

which are connected by hollow struts. Water for cooling

enters at the bottom of each water jacket and leaves at the top

through holes aligned with openings in the cylinder head. The

top surface of the cylinder block is counterbored at each water

or oil passage to accommodate individual seal rings.

b. Cylinder Block Removal.

(1) Remove the accessories (para 5-2).

(2) Remove the cylinder head (para 5-3). Do not

disturb components.

(3) Remove pistons, connecting rods, and rings

(4) Remove the cylinder liners (para 5-5).

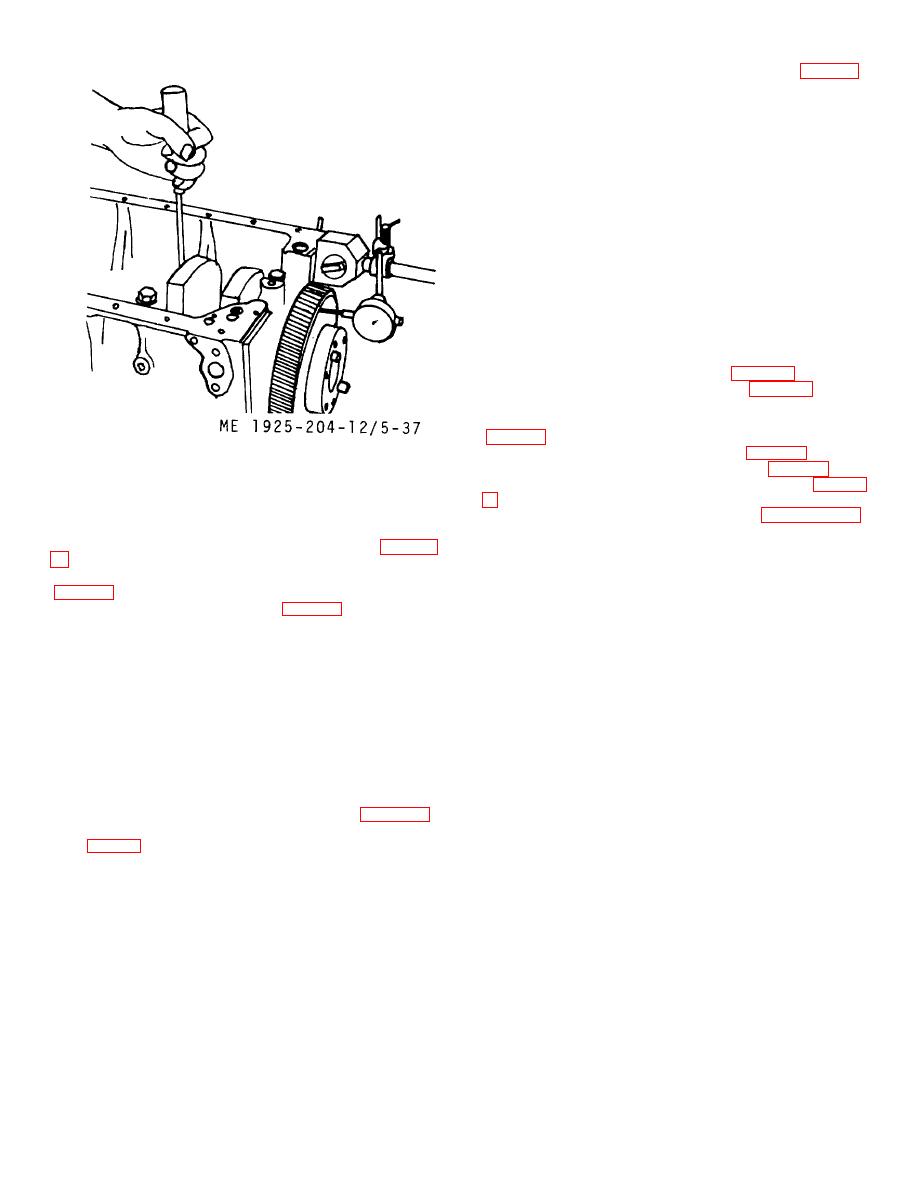

Figure 5-37. Checking cranking end play.

(5) Remove flywheel and housing (para 5-6).

(6) Remove camshaft and timing system (para 5-

(g) End play must be within 0.004 to 0.014

inch (with new parts), or a maximum of 0.018 inch with used

(7) Remove the crankshaft (para 5-8g.(1)),

parts.

removing and tagging all main bearing halves for identification

(h) Install connecting rod bearings (para 5-

so that all pieces are reinstalled in their original positions.

c. Cleaning, Inspection, and Repair of Cylinder Block.

(i) Install new gasket and flywheel housing

(1) If the cylinder block was removed because of

a known defect, proceed to NOTE below and clean up the new

(j) Install flywheel (para 5-6).

cylinder block. Then, proceed to d. below and install the new

(k) Install crankshaft front cover (f. above).

block.

(l) Install vibration damper (e. above).

(m) Install crankshaft pulley (d. above).

NOTE

(n) Install the lubricating oil pump (c. (3)

Replacement

cylinder

block

(d) above).

assemblies include the numbered

(o) Install a new gasket to oil pan bolting

main bearing caps and bolts, cylinder

flange, then secure oil pan to the cylinder block with

head studs and bolts, dowel pins,

lockwashers and capscrews.

cylinder liners, and all plugs installed

(p) Add strain to chain hoist and remove

in holes requiring them. But, it must

blocks, then lower engine to mounting bed, being careful to

be cleaned to remove corrosion and

allow for dowels on flywheel to line up with power generator

rust preventive compound before it

mounting flange.

can be installed.

(q) Reconnect power generator (para 5-29).

(r) Secure engine to bed with mounting

bolts (fig. 5-7).

5-44

|

||

|

||