| Tweet |

Custom Search

|

|

|

||

(8) Remove all capscrews securing the heat

KEY to fig. 5-55:

15.

Capscrew

exchanger to the engine, then lift heat exchanger to a suitable

1. Gasket

16.

Hose

work area.

2. Core

17.

Hose clamp

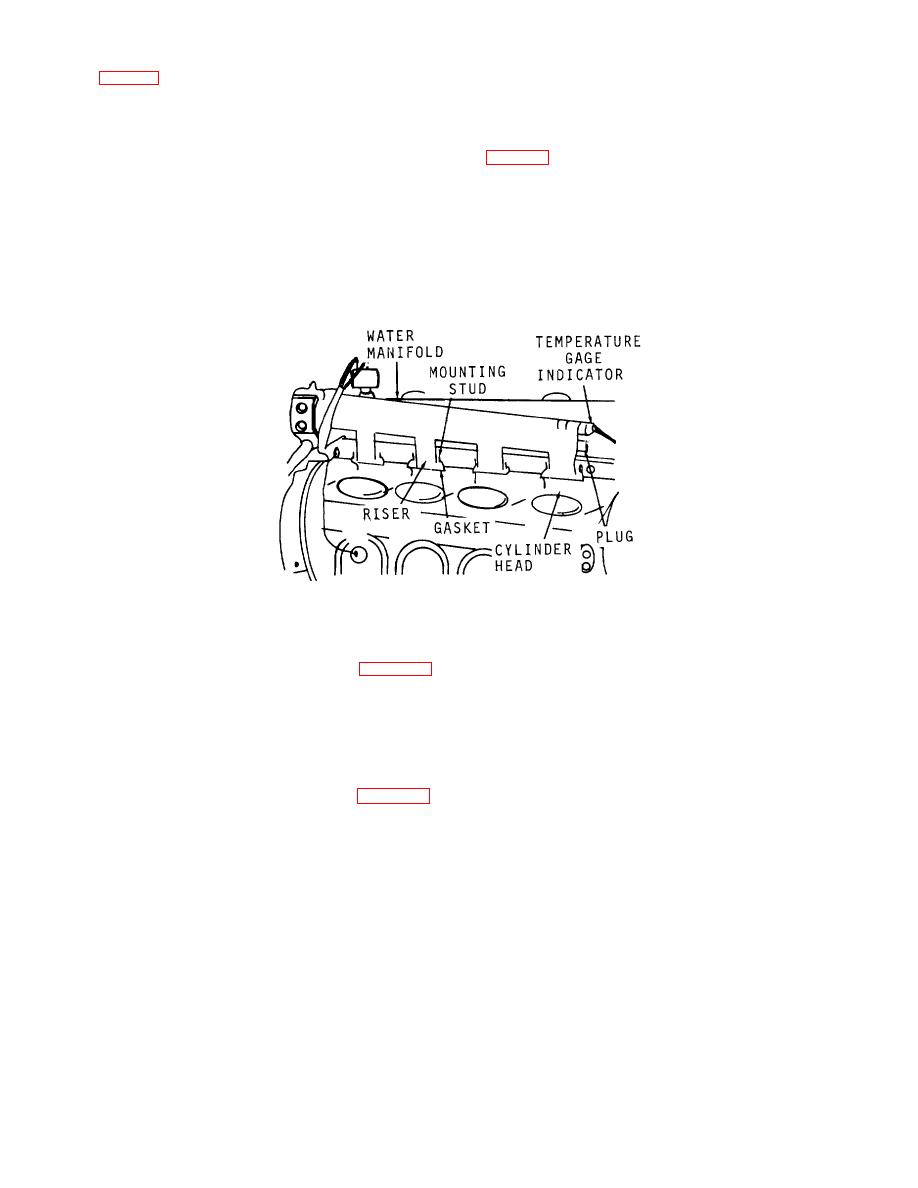

(9) Remove the water manifold as follows:

3. Gasket

18.

Elbow

(a) Disconnect temperature gage indicator

4. Cover

19.

Flange

5. Lockwasher

20.

Gasket

(b) Remove two nuts from studs at the four

6. Capscrews

21.

Housing

risers, then lift water manifold from the cylinder head.

7. Capscrews

22.

Gasket

Remove the four gaskets.

8. Plug

23.

Lockwasher

9. Gasket

24.

Gasket

10. Spring

25.

Lockwasher

11. Valve

26.

Bolt

12. Tube assembly

27.

Capscrew

13. Gasket

28.

Lockwasher

14. Lockwasher

Figure 5-56. Typical water manifold mounting.

c. Disassembly.

d. Cleaning, Inspection, and Repair.

(1) Remove raw water components as follows:

(1) Wash all hardware in clean fuel oil and blow

(a) Remove capscrews (20, fig. 5-54),

dry with compressed air.

cover (15), and gasket (14).

(2) Clean oil cooler core by directing a jet of

(b) Remove retainer (6), gasket (10), and

steam into the inlet side. Wash the interior with water after

rings (11), then pry on flange of core (13) and remove it from

steaming, warm the unit to remove all traces of water.

the heat exchanger. Remove the electrode assemblies (1)

(3) If the raw water core, or the water manifold

from covers (15 and 7).

are scaled, clean by soaking in a solvent (FED SPEC P-D-

(2) Remove oil cooler and fresh water

680), then blow dry with compressed air. If some scale is still

components as follows:

there, use a wire brush and remove all traces. Clean all

(a) Remove capscrews (27, fig. 5-55),

gasketing surfaces thoroughly.

lockwashers (28), then remove fresh water suction line flange

(19) and gasket (20).

NOTE

(b) Remove

two

capscrews

(7),

The manufacturer recommends an

lockwashers (23) and bypass valve housing (21). Then

alternate procedure, with a mixed scale

remove gasket (22) from housing.

solvent consisting of (1/3) muriatic acid

(c) Remove capscrews (6), lockwashers

and (2/3) water to which one-half (1/2)

(5), cover (4), and gasket (3).

pound of oxalic acid has been added for

(d) Pull core (2) from the heat exchanger

each 2 1/2 gallons of the solution.

housing, then remove gasket (13).

Remove the core or manifold when the

(e) Remove plug (8), gasket (9), spring

bubbling and foaming stops.

This

(10), and valve (11) from oil bypass valve housing (21).

usually takes from 30 to 60 seconds,

then flush thoroughly with clean hot

water under pressure.

5-71

|

||

|

||