| Tweet |

Custom Search

|

|

|

||

threads of nipple with white lead, then install new relief valve

(3) Boiler repairs. Inspect, and repair by replacing

by turning it clockwise until tight.

the following items when defective:

(b) Inspect the observation doors for

(a) Inspect the safety relief valve operation

breaks, tears, or other defect. Remove and replace a

by moving the lever out away from valve body while the boiler

defective door.

is at work. If steam does not escape, shutdown the boiler,

b. Burner and ignition.

vent all steam and replace the defective safety relief valve by

turning it counterclockwise until it is free of the nipple. Fill

(1) Removal.

(a) Remove cover (19, fig. 5-111).

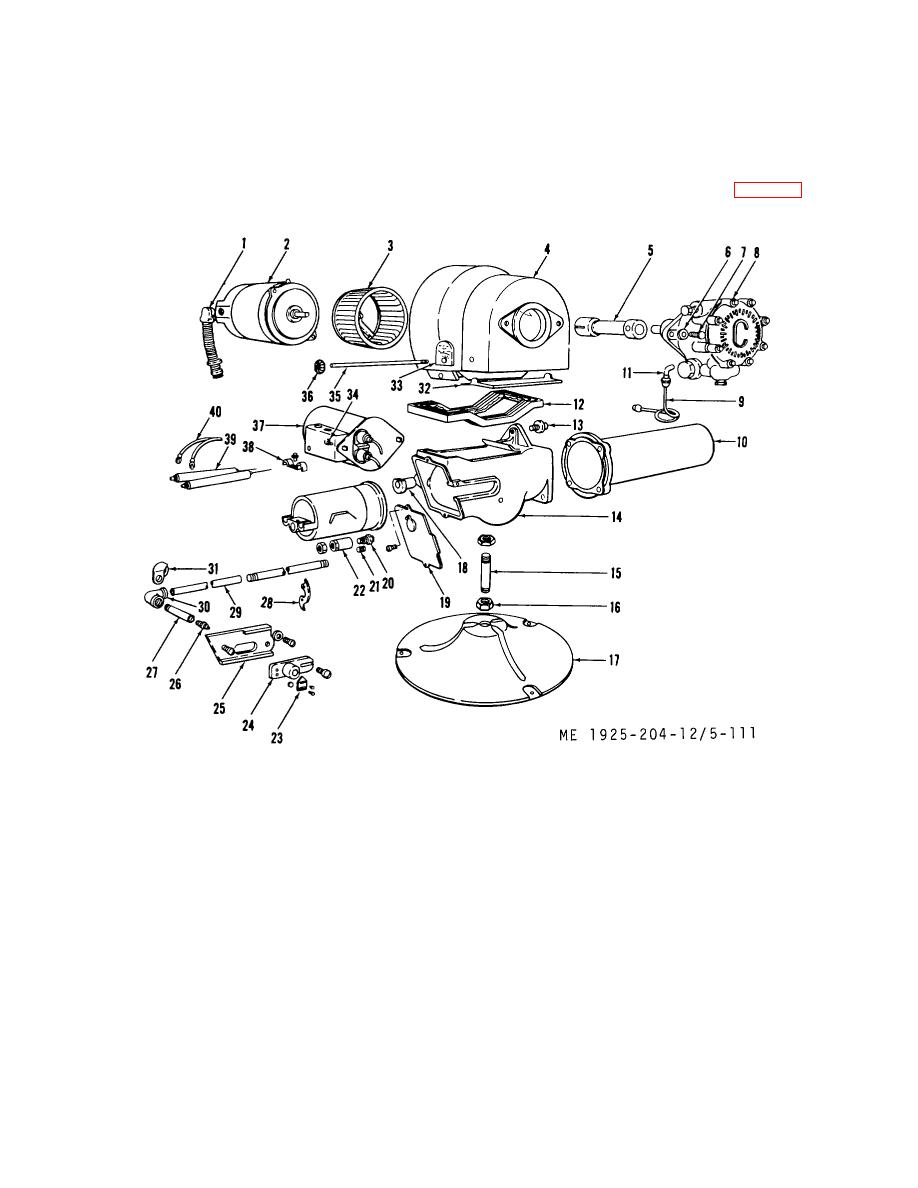

Figure 5-111. Oil burner assembly

1.

Conduit

11.

Elbow

22.

Adaptor

33.

Dial

2.

Motor

12.

Gasket

23.

Indicator

34.

Screw

3.

Fan

13.

Front bushing

24.

Bracket

35.

Rod

4.

Upper housing

14.

Lower housing

25.

Plate

36.

Knob

5.

Coupling

15.

Base nipple

26.

Connector

37.

6.

Lockwasher

16.

Locknut

27.

Nipple

ignition

7.

Capscrew

17.

Base

28.

Support

38. Clamp

8.

Fuel pump

18.

Rear bushing

29.

Tube

39. Electrode

9.

Tube

19.

Cover

30.

Elbow

40. Cable

10.

20.

Oil burner nozzle

31.

Insulating elbow

manifold

21.

Strainer

32.

Shutter

(b) Disconnect electrical connections in cable (40)

(d) Loosen setscrews remove thumbscrew and

from electrodes (39).

slip adjusting bracket from fuel connection.

(c) Disconnect fuel line connector (26) at slide

(e) Remove screws, and lift off cover plate (25).

adjustment bracket (24).

5-153

|

||

|

||