| Tweet |

Custom Search

|

|

|

||

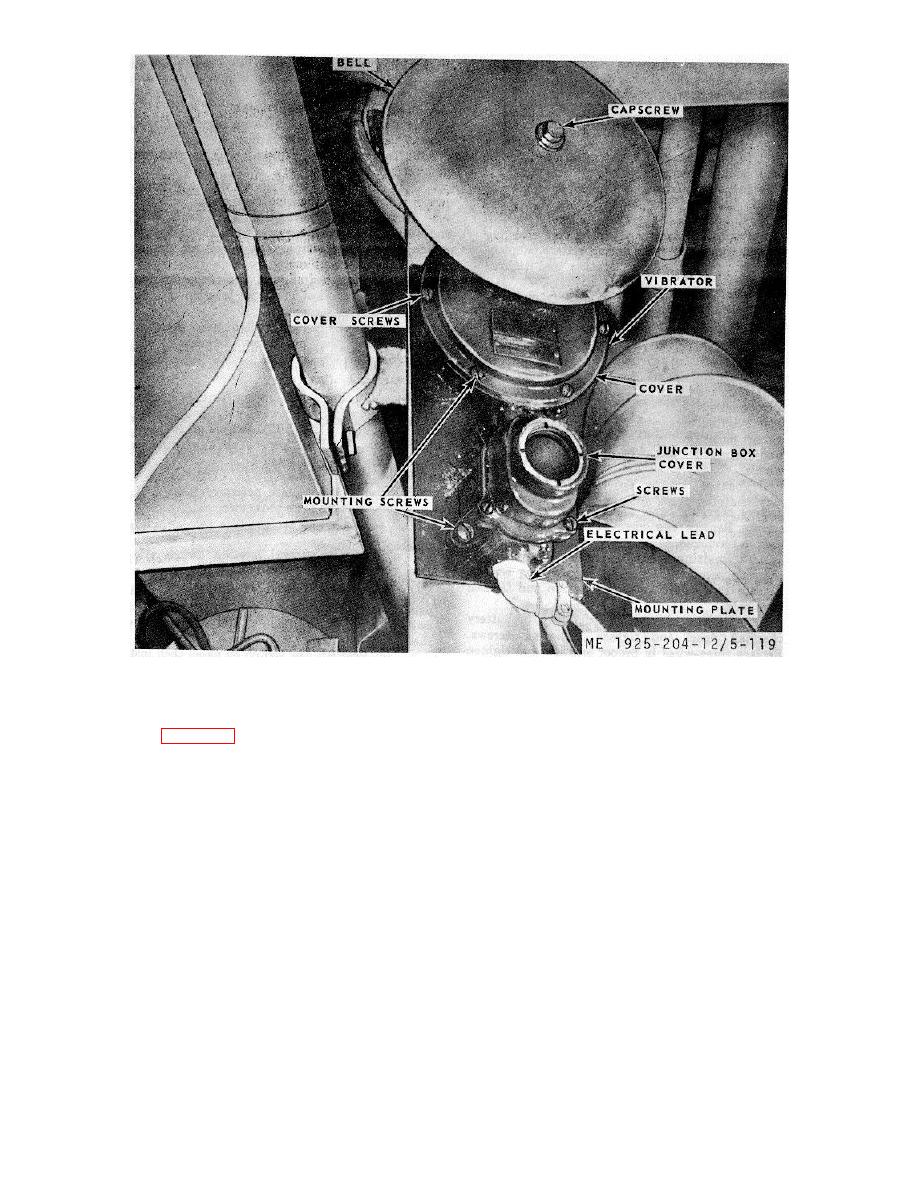

Figure 5-119. Engineroom general alarm bell

b. Removal. (1) Tag and disconnect the

(1) Use low pressure compressed air (10

electrical leads (fig. 5-119).

psi) and blow dust and dirt from the bell assembly

(2) Remove mounting screws, then lift bell

components within housing.

assembly off the mounting plate.

(2) Inspect vibrating clapper for bends or

c. Disassembly.

other defect.

Inspect all electrical terminals for

(1) Remove capscrew, then lift bell off the

corrosion.

assembly.

(3) Test continuity of all electrical circuits

(2) Remove cover screws, then lift cover

(4) Repair by replacing a defective bell

off the vibrator.

assembly.

(3) Remove screws from junction box

e. Reassembly. Assemble by reversing the

cover, then lift cover from the junction box.

procedure in c. above.

d. Cleaning, Inspection, and Repair.

f. Installation. Install by reversing the procedure

in b. above.

5-172

|

||

|

||