| Tweet |

Custom Search

|

|

|

||

TM 55-1925-273-10-2

0138 00

Table 1. Preventive Maintenance Checks and Services Chart (continued)

ITEM INTERVAL MAN-

ITEM TO BE

PROCEDURE

EQUIPMENT

NO.

HOUR

CHECKED OR

NOT READY/

SERVICED

AVAILABLE IF:

66

During

1.0

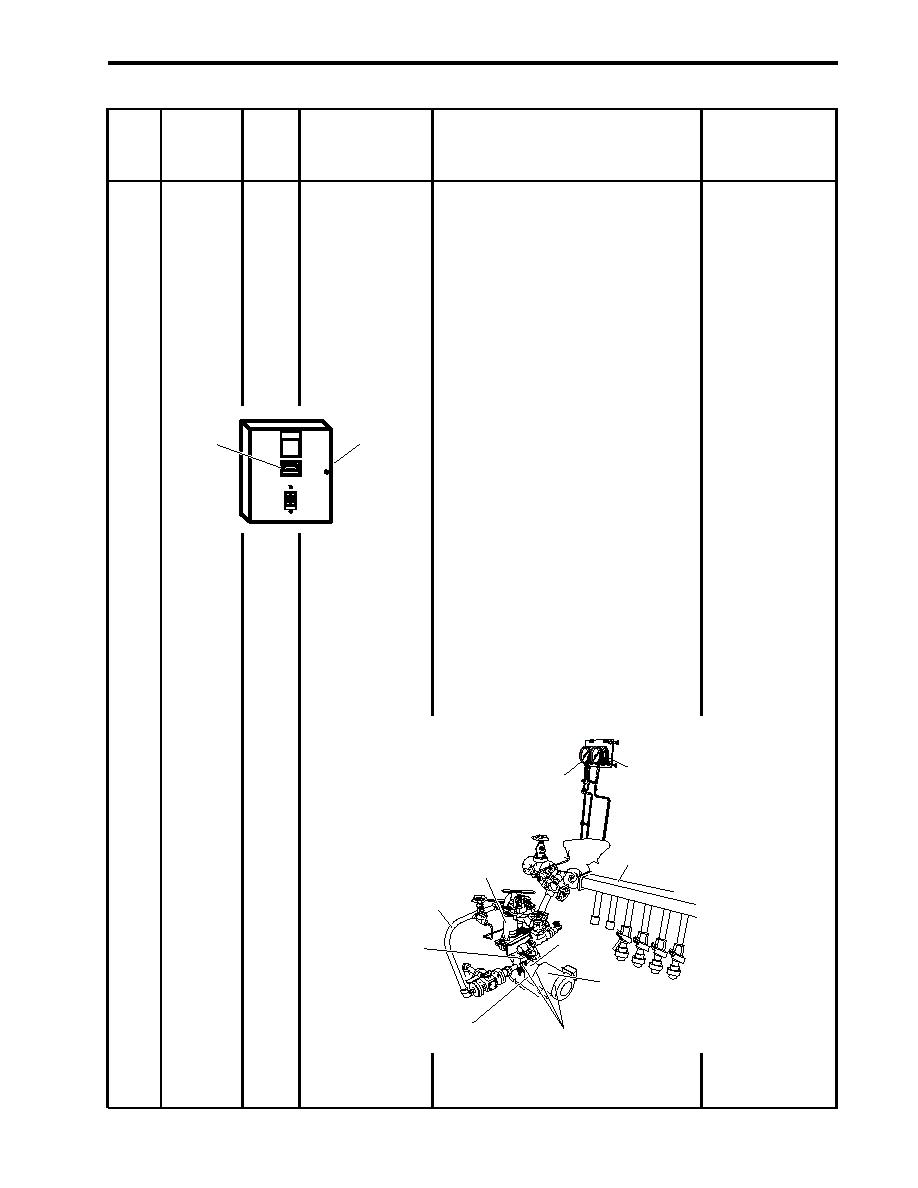

BATTERY

a. At 120V emergency distribution panel

CHARGERS

No. 1, checj that the SSDG No. 1

(SSDG 1,

BATTERY CHARGER. and

MACHINERY DC

MACHINERY DC CONTROL

CONTROL,

BATTERY CHARGER. circuit

ROWPU)

breakers are set to ON.

b. At 120V distribution panel No. 4,

check that the ROWPU BATTERY

CHARGER. circuit breaker is set to

ON.

c. Check battery chargers for proper

Battery

connections to battery.

Charger

NOTE

A high reading indicates that the batteries

are weak and are being recharged or that

one or more batteries are unserviceable.

d. Check the ammeter reading. The

Unit fails to operate

ammeter should read near 0 for a

and recharge the

trickle charge. If the reading is above

batteries

3 AMPS, refer to unit maintenance.

67

After

0.3

LUBE OIL

Visually inspect pumps for leaks, loose

Pumps are

TRANSFER PUMP

connections, and damage.

defective.

Lube Oil Transfer

Lube Oil Transfer

Pump Discharge

Pump Differential

Pressure Gauge

Pressure

Lube Oil Manifold

And Piping

Strainer

Piping

Coupling

Pump

Electric

Motor

Lube Oil

Grease Fitting

Transfer Pump

0138 00-27

|

||

|

||