| Tweet |

Custom Search

|

|

|

||

TM 55-1925-273-10-2

0140 00

Table 1. Preventive Maintenance Checks and Services Chart (continued)

ITEM INTERVAL MAN-

ITEM TO BE

PROCEDURE

EQUIPMENT

NO.

HOUR

CHECKED OR

NOT READY/

SERVICED

AVAILABLE IF:

PUMP DRIVE

ENGINE

8

Before

0.2

Air Starter

Visually inspect bowl. Cup must be at

Oiler Bowl

least full. Add oil (OE/HDO-10) as

required.

9

Before

0.2

Engine Crankcase

With engine turned off, check oil

Oil

dipstick. Oil level should be between the

ADD and FULL marks on the dipstick.

Add oil (OE/HDO-30) as required.

WARNING

Engine coolant may be hot.

Contact with hot coolant

can cause serious injury or

death.

10

Before

0.2

Cooling System

Check coolant level at the coolant level

gauge. Gauge should read FULL. Add

coolant (50/50 mix of antifreeze and

water) as required.

11

Before

0.2

Mounting Fixtures

Inspect for damaged or missing parts.

12

Before

0.2

Heat Exchanger

Inspect for leaks, sponginess, or other

Damaged or missing

Connecting Lines

damage.

parts. Class III leaks

13

Before

0.2

Flexible Hoses

Inspect for leaks, sponginess, or other

damage.

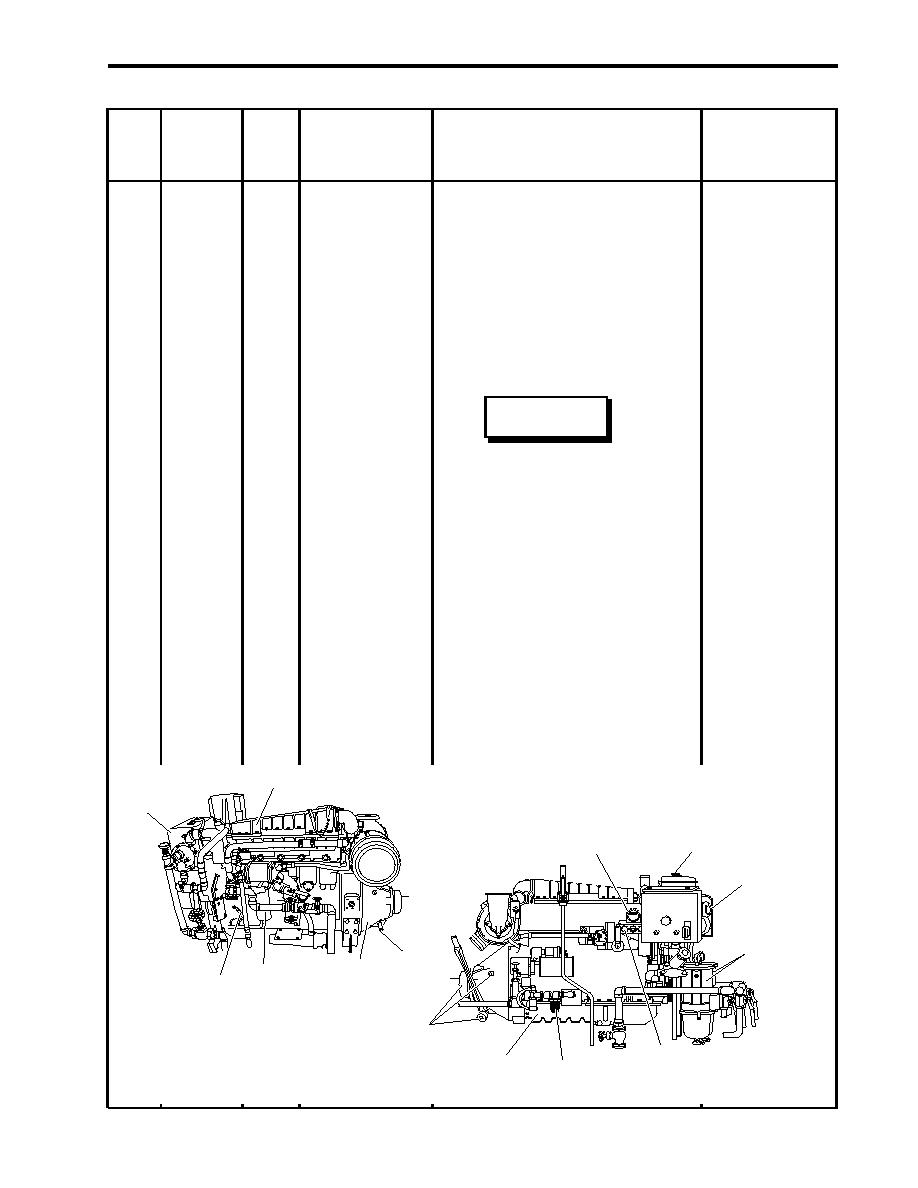

Pump Drive Engine

Expansion

Tank

Filler Cap

Coolant Level

Gauge

Fuel Filter

Water Separator

Grease

PTO

Oil Filter

Fitting

Dipstick

Grease

Fittings

Gauge

Pump Drive

Panel

Air Starter

Engine

Oiler Bowl

0140 00-3

|

||

|

||