| Tweet |

Custom Search

|

|

|

||

TM 55-1925-273-10-2

0141 00

Table 1. Preventive Maintenance Checks and Services Chart (continued)

ITEM INTERVAL MAN-

ITEM TO BE

PROCEDURE

EQUIPMENT

NO.

HOUR

CHECKED OR

NOT READY/

SERVICED

AVAILABLE IF:

94

Monthly

0.5

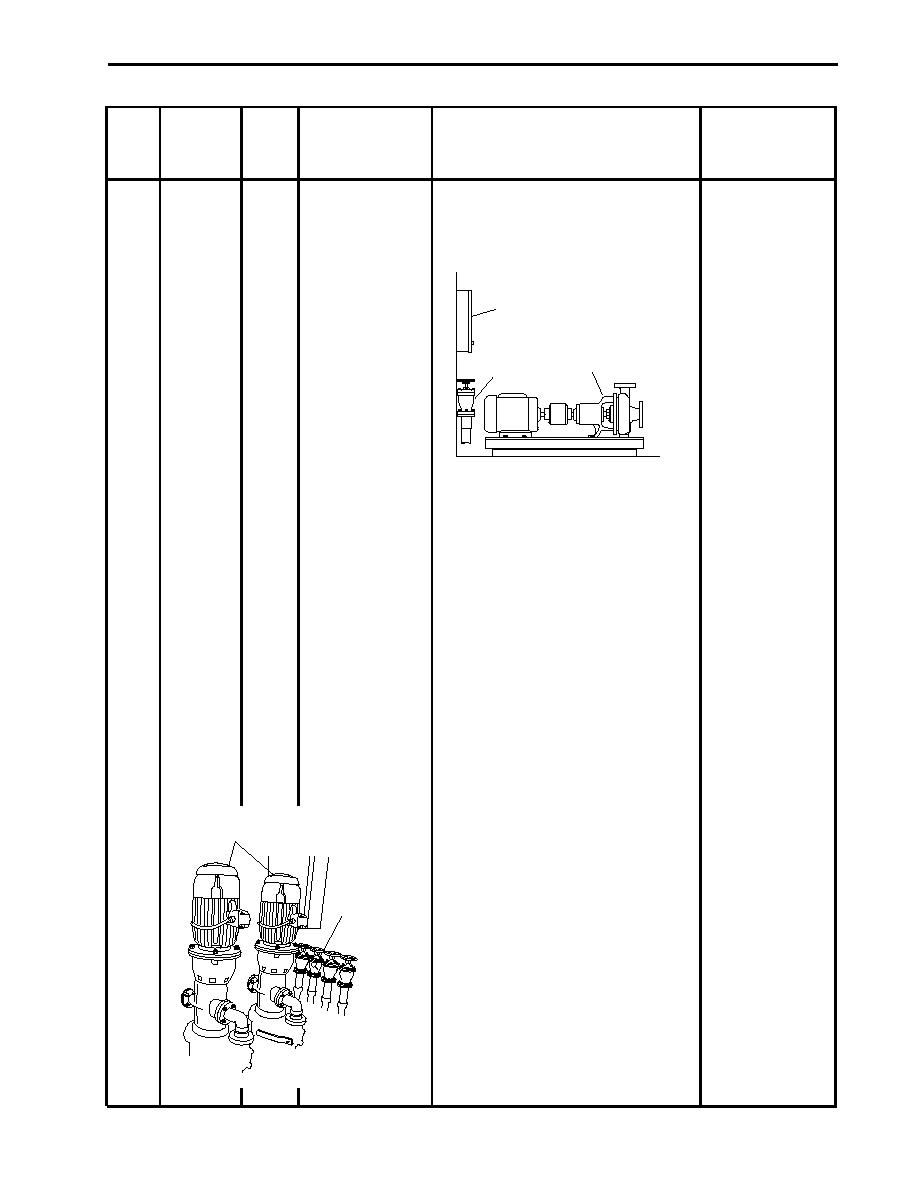

BILGE

Visually inspect manifold for cracks,

Class III leaks or

MANIFOLD

leaks, and secure mounting.

loose mounting.

Bilge/Ballast

Motor Controller

Bilge/Ballast Pump

Bilge Manifold

95

Monthly

0.5

FIRE AND

a. Check pumps, couplings, and sea chest

Sea chest cannot be

GENERAL

valves for proper operation. Sea chest

cleared, and suction

SERVICE PUMPS

is clogged when suction pressure is

pressure cannot be

greater than 10 in Hg (254 mm Hg)

lowered below

10 in Hg

(254 mm Hg).

b. Check gauges for normal readings.

Fire main discharge

Fire main discharge pressure should

pressure above

be 60 to 120 PSI (4.1 to 8.3 bar)

120 PSI (8.3 bar)

against dead head.

or below 60 PSI

(4.1 bar).

c. General service pressure should be

Unable to maintain

greater than 60 PSI (4.1 bar) under

general service

normal operating conditions.

at 50 lb/in (3.45

bar) under normal

operating conditions.

Fire and General

Service Pumps

d. Apply 1-2 pumps of general purpose

grease to the grease fittings located on

each end of the electric motor and on

the input shaft housing of the pump.

Bilge Manifold

0141 00-25

|

||

|

||