| Tweet |

Custom Search

|

|

|

||

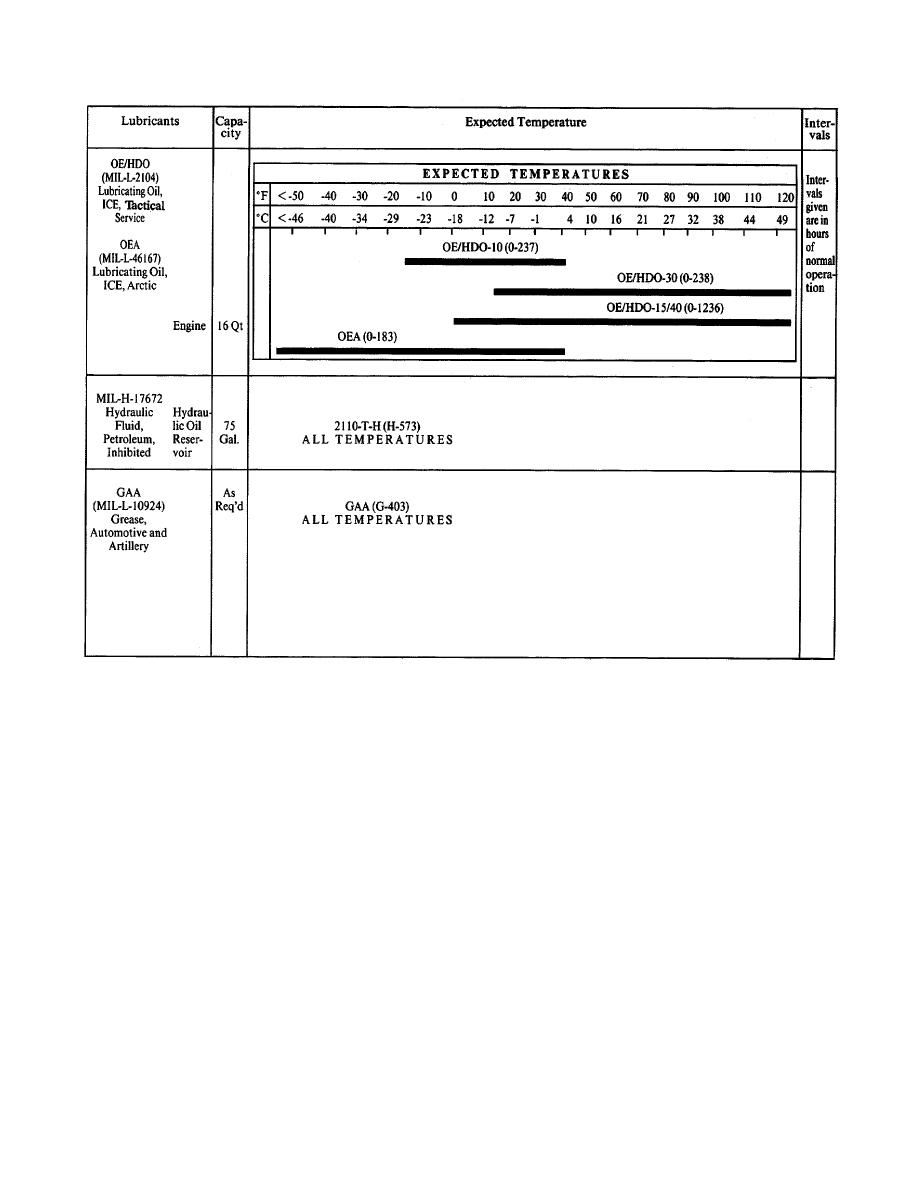

LO 5-2010-205-12

Notes:

1. FOR OPERATION OF EQUIPMENT IN PROTRACTED COLD TEMPERATURE BELOW-10 deg F (-23 deg C).

Remove lubricants prescribed in the key for temperatures above -10 deg F (-23 deg C). Clean parts with SOLVENT, dry-

cleaning (SD-II). Relubricate with lubricants specified in the key for temperatures below -10 deg F (-23 deg C).

2. HYDRAULIC RESERVOIR. Remove oil reservoir filler cap and check strainer. Clean if necessary and install strainer.

Remove drain plug and drain. Clean and install drain plug. Refill reservoir with HRO. Proper level of oil is at high mark.

3. When AOAP Laboratory support is not available, drain and refill crankcase at 500 hours or 6 months.

4. Install filters, fill crankcase. Operate at idle and inspect for leaks. Shut off engine, and allow 5 minutes for oil to drain

to crankcase. Check oil level with dipstick.

5. Check crankcase level with engine shutdown.

6. A sample of oil shall be sent to an AOAP Laboratory for analysis at an interval of 50 hours or 30 days. Refer to TB 43-

0210 for sampling requirements.

7. Oil filters will be changed at the same time as the oil is changed.

8. Fuel filters will be changed at 250 hours or quarterly.

9. Expansion tank coolant will be changed at every 2000 hours or two years.

10. Hydraulic system filters will be changed every 1000 hours or annually.

Card 2 of 3

|

||

|

||