| Tweet |

Custom Search

|

|

|

||

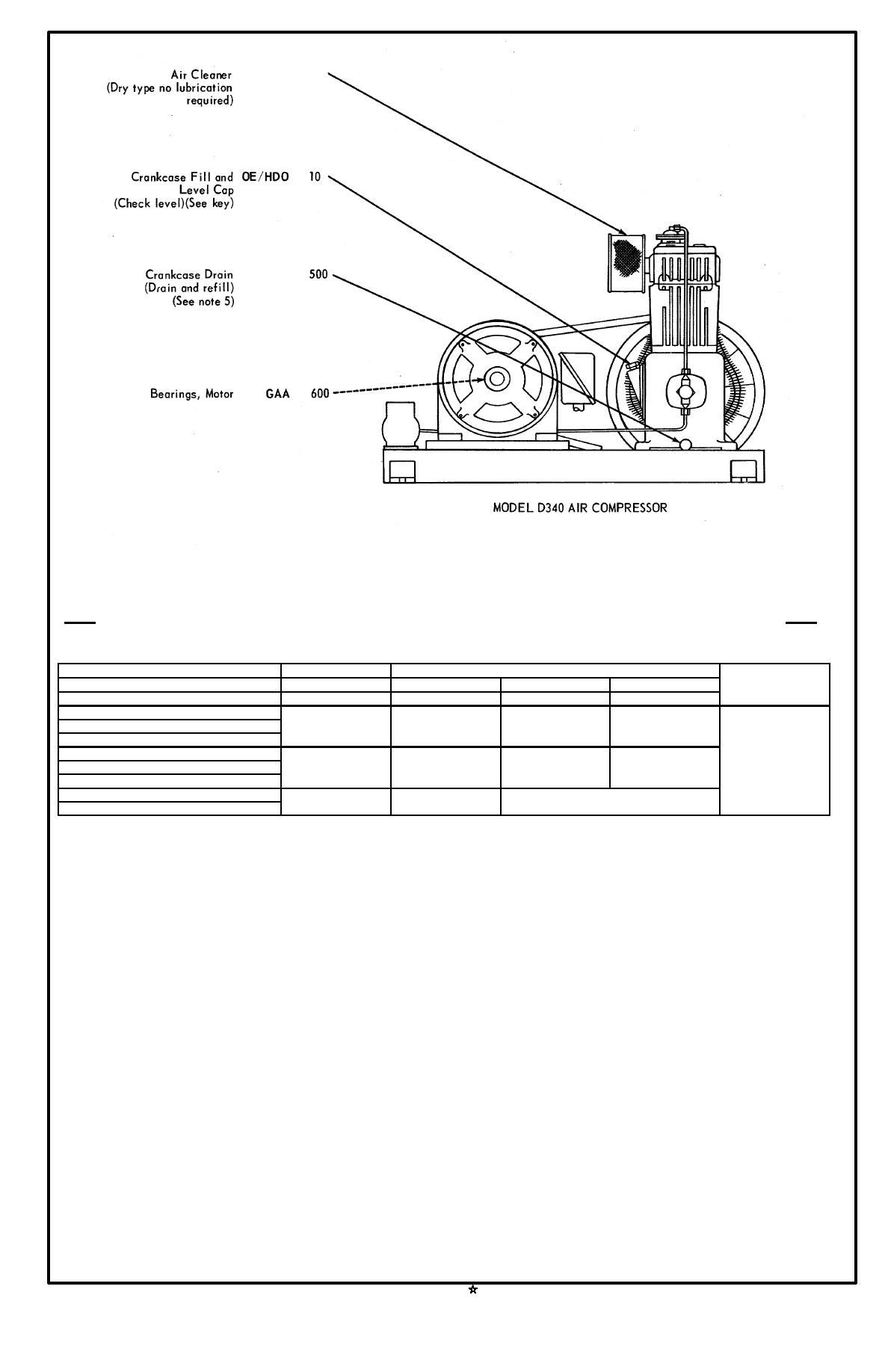

MODEL D340 AIR COMPRESSOR

FOLD

FOLD

-KEY-

EXPECTED TEMPERATURES

LUBRICANTS

CAPCAITY

INTERVALS

Above + 32F

+ 40F to - 10F

0F to - 65F

OE/HDO-LUBRICATING OIL, Engine

Compressor Crankcase

6 qts

OE/HDO 30

OE/HDO 10

OES

OES-LUBRICATING OlL, Sub-zero

Intervals

GO-LUBRICATING OIL, Gear of

given are

Capstan Worm Gear Case

10 gal

GO 90

GO 80

GOS

in hours of

GOS-LUBRICATING OIL, Gear Sub-zero

normal

CW-LUBRICATING OIL, Exposed gear

CW-II

operation

GAA-GREASE, Auto & Artillery

ALL TEMPERATURES

NOTES:

5. COMPRESSOR. Change oil every 500 hours or every 90 days

1. FOR OPERATION OF EQUIPMENT:IN PROTRACTED COLD

TEMPERATURES BELOW -10F. Remove lubricants prescribed in the

whichever occurs first.

key for temperatures above -10 . Relubricate with lubricant specified in

F

the key for temperatures below -10 .

F

Copy of this Lubrication Order will remain with the equipment at all times;

instructions contained herein are mandatory.

2. OIL CAN POINTS. Every 50 hours clean arid lightly coat control

BY ORDER OF THE SECRETARY OF THE ARMY

linkages, hinges, and all exposed adjusting threads with OE/HDO.

CREIGHTON W. ABRAMS

General, United States Army

3. LUBRICANTS: The following is a list of lubricants with the Military

Chief of Staff.

Symbols and the applicable specification numbers.

OFFICIAL:

OE MlL-L-2104C

OES MIL-L-10295

GO Ml L-L-2105

GAA MIL-G-10924

GOS Ml L-L-10324

CW VV-L-751

VERNE L. BOWERS

Major General, United States Army,

4. WORM GEAR. Change oil every 2400 hrs or every year whichever

The Adjutant General

occurs first.

DISTRIBUTION: To be distributed in accordance with DA Form 12-

25D (qty rqr block No. 813) Operator' Maintenance requirements

s

for Marine Equipment: All.

L055-1925-204-12-4

U.S. GOVERNMENT PRINTING OFFICE: 1973 O-518-888

|

||

|

||