| Tweet |

Custom Search

|

|

|

||

LUBRICATION ORDER

LO55-1930-203-12

31 DECEMBER 1987

(Supersedes LO55-1930-203-12

Dated 15 October 1986

LIGHTER, AMPHIBIOUS (LARC LX) SELF-PROPELLED, DIESEL 60 TON,

61 FT. DESIGN 2303, HULLS 5 THROUGH 60 W/ENGINES

DETROIT DIESEL MODELS 6080 AND 6081

References:TM55-1930-203-10,-20 andC9100-IL

Approved for public release. Distribution is unlimited.

Intervals (on-condition or hard time) and the related man-hour times are

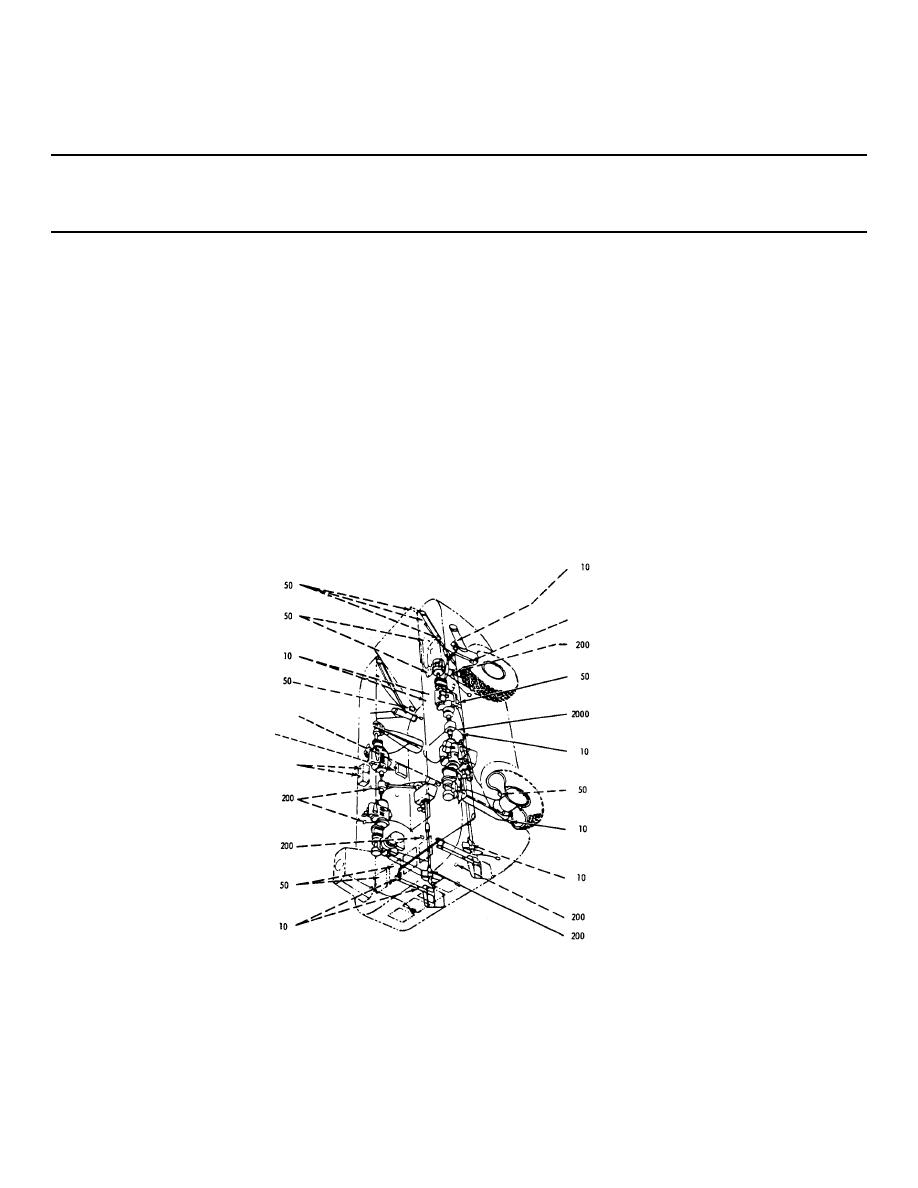

Lubricate points indicated by dotted arrow shafts on both sides of

based on normal operation. The man-hour time specified is the time you

equipment.

need to do all the services prescribed for a particular interval. On-

condition (OC) oil sample intervals shall be applied unless changed by the

Drain wet crankcases, gear boxes and hydraulic reservoirs while the

Army Oil Analysis Program (AOAP) laboratory. Change the hard time

lubricant is still warm from previous use.

interval if your lubricants are contaminated or if you are operating the

equipment under adverse operating conditions, including longer-than-

You can help improve this manual. If you find any mistake or if you know

usual operating hours. The hard time interval may be extended during

of a way to improve the procedures, please let us know. ARMY Mail DA

periods of low activity. If extended, adequate preservation precautions

Form 2028 (Recommended Changes to Publications and Blank Forms),

must be taken. Hard time intervals will be applied in the event AOAP

to: Commander, U.S. Army Troop Support Command, ATTN: AMSTR-

laboratory support is not available.

MCTS, 4300 Goodfellow Boulevard, St. Louis, MO 63120-1798. A reply

will be furnished directly to you.

Clean fittings before lubricating.

Level of maintenance. The lowest level of maintenance authorized to

Clean parts with SOLVENT, dry-cleaning, (SD), type II or equivalent.

lubricate a point is indicated by one of the following symbols as

appropriate: Operator/crew (C); and Organizational Maintenance (O).

Dry before lubricating.

LUBRICANT INTERVAL

INTERVAL LUBRICANT

FOLD

FOLD

1

Romp Hoist Sheave

GAA

OE

Lubricator Cargo *

10

Well Pump Shaft

2

Hatch Dog

GAA

(Adjust oil drip-

(See note 2.)

lubricator to meter

3-5 drops per minute)

3

Ramp Hinge

WTR

WTR

Wheel Spindle Grease

(See note 3.)

Retainer (See note 80)

58

Romp Seal

GAA

GAA

Bilge Drain Valve

6

Protector

Handwheel

Wheel Spindle Grease WTR

(2 fittings)

Retainer (See note 8a)

OE

Rudder Control e

11

4

Hydraulic Oil Tank

OE

Cable

Fill Cap

(See note 6.)

(See key)

Hydraulic Oil Tank-,

12

5

Hydraulic Oil Tank

OE

Drain Plug

Fill Cap

(Drain and refill)

(See key)

Hydraulic Oil Tank

6

Bilge Drain Valve

GAA

Sight Level Gage

Handwheel

(Check level)

(2 fittings)

WTR

Wheel Seal a

13

7

-Bilge Drain Valve

GAA

(1 each column)

Coupling

(See note 8.)

8

Radiator Fans

GAA

WTR

Wheel Column Sup- =

4

(See note 4.)

port Bearing

9-

Rudder Stock Bush-

WTR

(1 each column)

ing

(See note 8.)

(See note 5.)

WTR

Propeller Strut

15

Bushing

(See note 9.)

GAA

Bilge Pump

16

GAA

Bilge Pump Valve m

6

Handwheel

(2 fittings.)

TS 015525

Card 1 of 10

|

||

|

||