| Tweet |

Custom Search

|

|

|

||

TB 55-1900-201-45/1

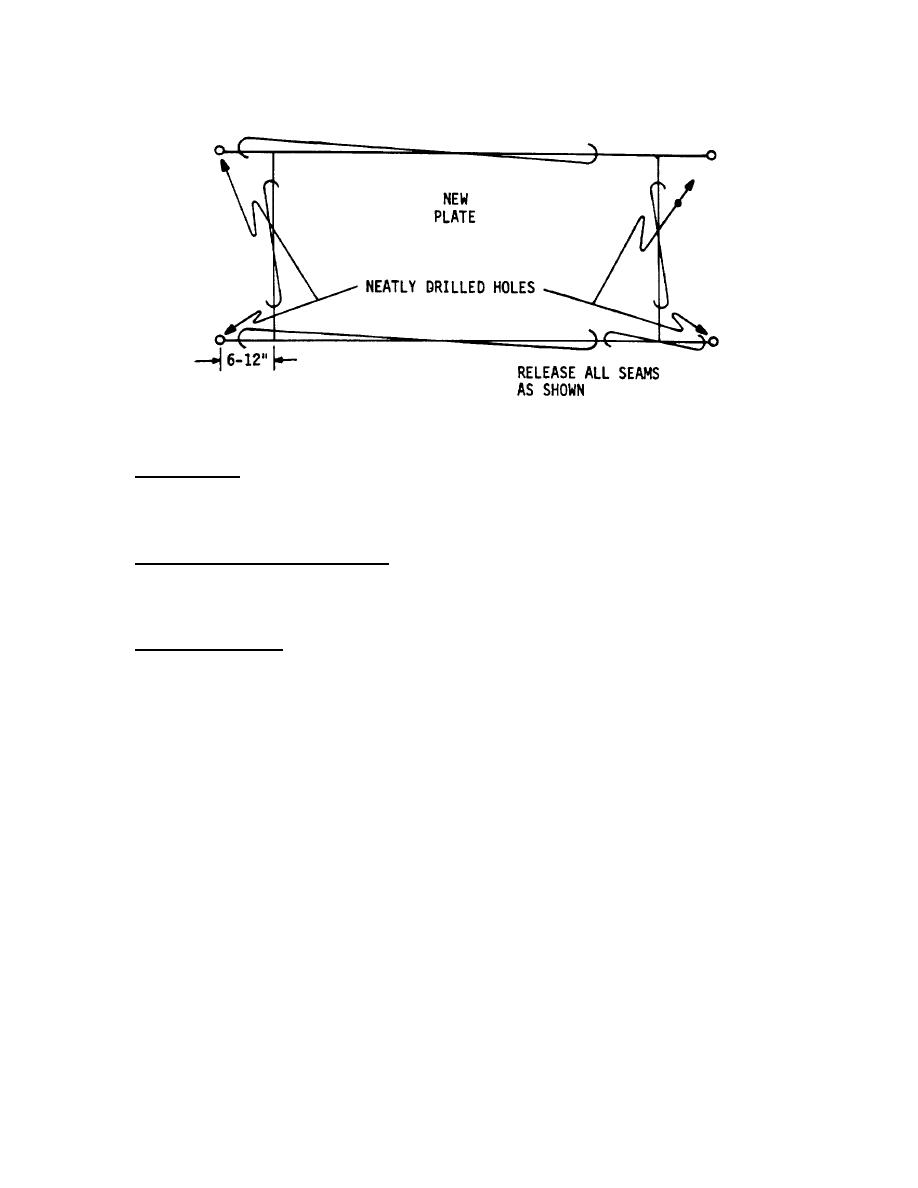

Proper Welding of Plate Section

(5) Undercut welds. Undercut butt and seam welds of shell, inner bottom and strength deck, or undercut fillet

welds attaching structural members thereto, should be avoided. This is particularly important for fillet welds near or at

the end of discontinuous longitudinal members, such as bilge keels, tanker longitudinals, deck clips, or foundation mem-

bers. Undercutting in these locations has contributed to complete hull girder fractures.

(6) Arc-strikes and light beads of welding. Arc-strikes and light beads of welding should be avoided on the sur-

face of strength deck, shell or tank-top plating, due to quench effect with possible subsequent crack stimulation. Arc-

strikes produce hard, brittle metal locally, containing microscopic cracks. It is recommended that such areas be chipped

out and re-welded using a pre- heat of at least 1500F.

(7) Projections or cavities. very often pads or lugs are welded to plates for the purpose of jacking the plates into

alignment and afterwards are knocked loose with a sledge. Any projections resulting from knocking off the lugs should

be chipped off and ground fair if necessary. If there are any cavities these should be welded flush.

b. Slugging, included slag, or submerged cracks cannot be determined by the surface appearance of welds. These

defects, however, can seriously reduce the strength of a welded joint and can provide the starting point for serious frac-

tures. Section 26 of the American Bureau of Shipping Rules for Building and Classing Steel Vessels

E-26

|

||

|

||