| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-

3-13. Storage Batteries, Cables, and Terminals (fig.

a. Inspection. Inspect batteries for leaks, corrosion,

proper electrolyte level, and breaks or cracks. Inspect

cables and terminals for corrosion and for broken cables

or terminals.

b Servicing and Testing.

(1) Clean batteries and terminals with a solution

of water and baking soda and wipe dry.

Keep batteries filled to proper level with electrolyte.

(2) Test the specific gravity of each cell with a

hydrometer. If the specific gravity reading is below 1.225

on the hydrometer, charge the battery. Specific gravity

readings of 1.260-to1.270 on the hydrometer indicate a

fully charged battery.

c. Removal.

(1) Disconnect and remove the negative lead,

then disconnect and remove the positive lead at the

battery.

(2) Remove battery.

d. Installation. Reverse procedure in c above, using

a fully-charged battery.

3-14. Hydraulic Steering System Filter

Observe the filter condition indicator (fig. 230) daily. The

filter element must be changed when the needle moves

into the red danger zone. If filter requires changing,

report to higher authority.

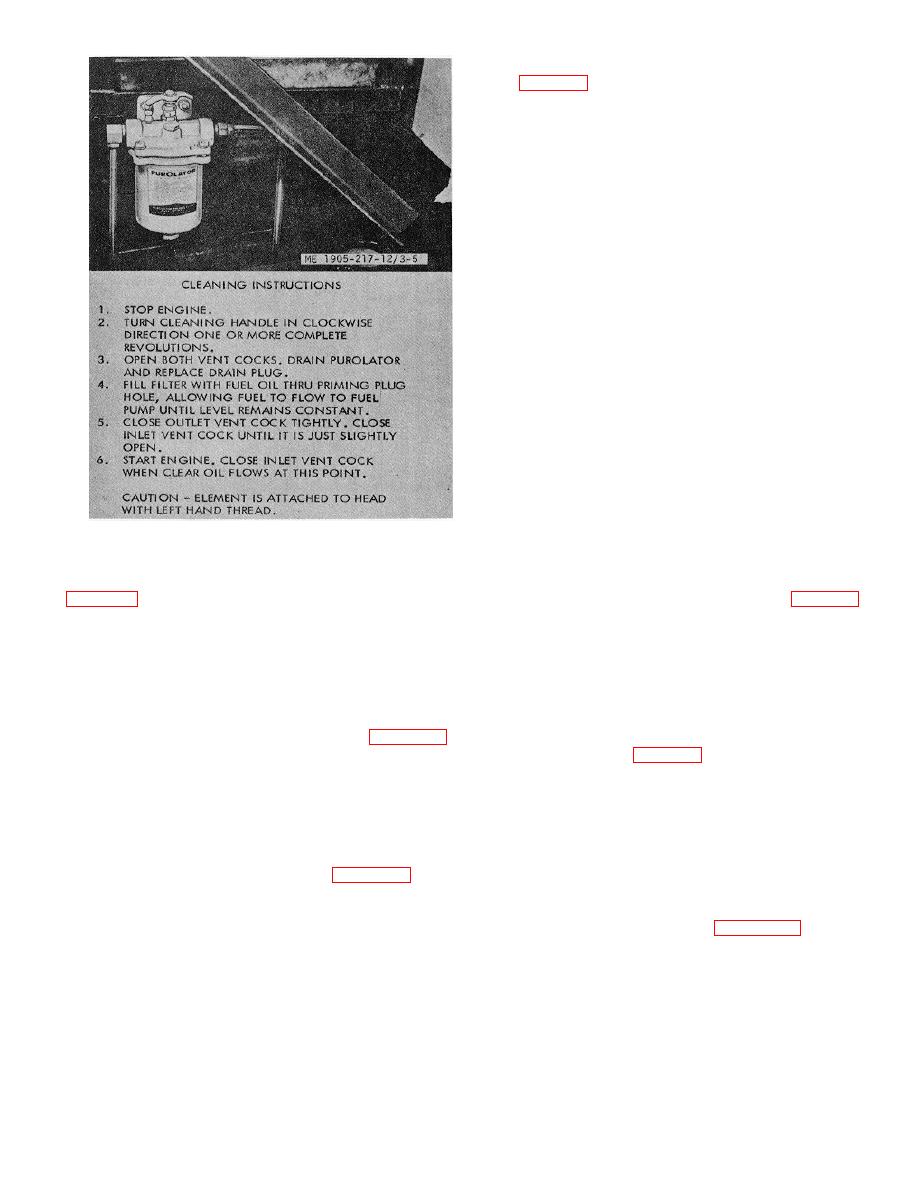

Figure 3-5. Primary fuel line strainers, hull numbers 8500

3-15. Ramp Hoist Hydraulic System Filter

thru 8519

Observe the filter condition indicator (fig. 2-29) daily

Crankcase breather screens are mounted between the

when system is in operation. The filter elements must be

engine blocks, and should be serviced every 8 hours.

changed when the needle moves into the red damage

zone. If servicing of filter ,is indicated, report to

organizational maintenance.

3-11. Alternators and Belt Adjustments

3-16. Ramp Hoist Hydraulic 'System Strainer (Hull

There are two alternators, one mounted on the inboard

Numbers 8500 thru 8519)

engine of each propulsion unit. The alternators are belt

driven from the crankshaft pulley. Refer to figure 3-8 for

alternator belt adjustment.

Check indicator (fig. 2-8.1) when ramp hoist ,system is in

operation. If servicing of strainer is indicated, report to

3-12. Fuses

organizational maintenance.

3-17. Bilge Pumps

Fuses are located in the distribution paned. The fuses are

15-amp, type AGU. Refer to figure 39 for fuse replacement.

In hull numbers 8540 thru 8560 and 8580 thru 8618 the

The landing craft is equipped with three bilge pump. Two

fuses are 10amp, type AGU. Refer to figure 2-5 for fuse

pumps ate mounted on the inboard engine of the port

location.

propulsion unit and one pump is mounted on the inboard

engine of the starboard propulsion unit. Adjust the bilge

pump belts as instructed in figure 3-11. Hull numbers

3-11

|

||

|

||