| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

If quick warm-up is attempted by burning the propeller,

the ship must be securely tied to the clock with no loose

lines or floating obstructions to foul the propeller.

(5) Set governor no-load top speed. Usually the

top no-load speed is set the same on both governors of

twin units before the engines leave the factory. If check

as outlined below shows top no-load speeds to be

different on the two governors, correct as follows:

(a) With both engines warmed up, stop engines and

disconnect throttle control rod (11, fig. 4-27) for "B"

engine by removing pin at clevis (14).

(b) Start "D" engine, declutch and move master

throttle to "FULL" open position.

(c) Note and record maximum no-load speed as

indicated by tachometer.

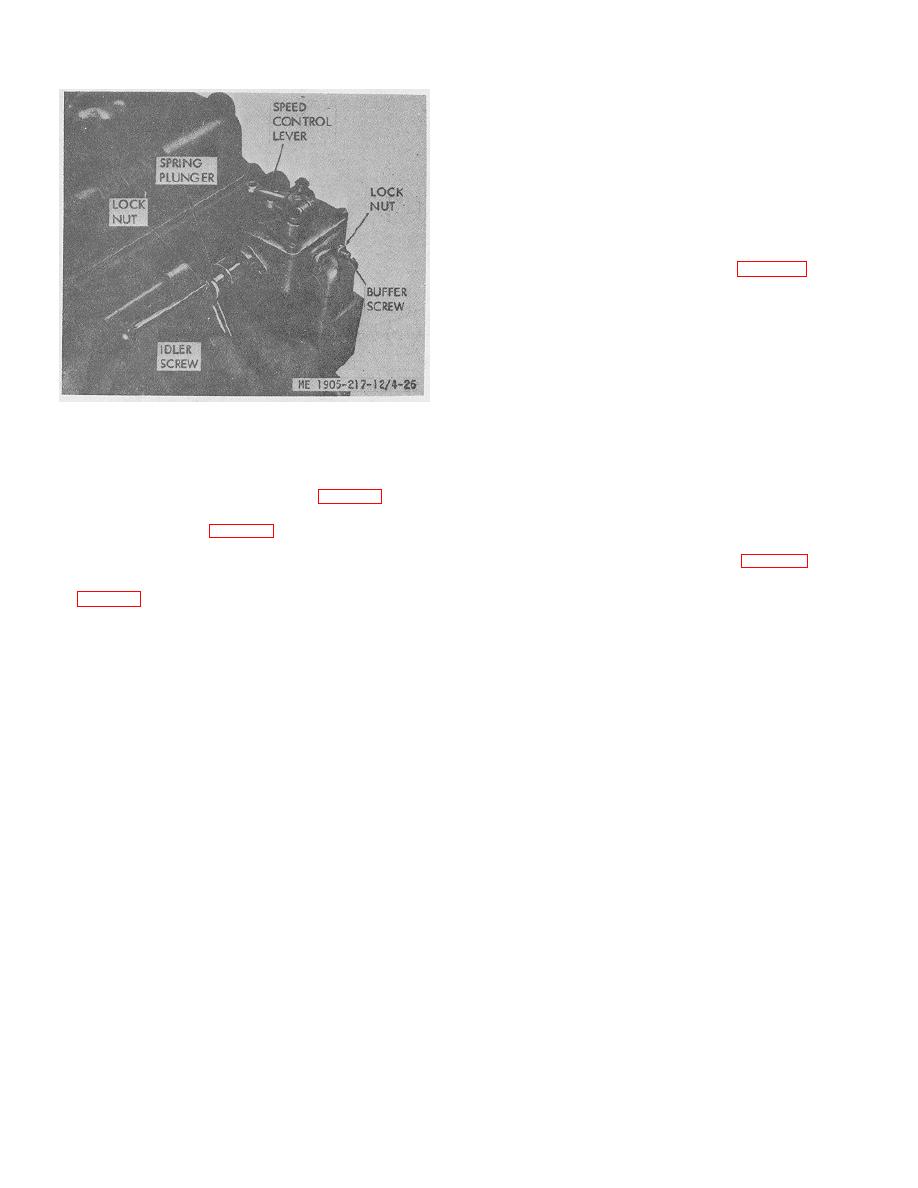

Figure 4-26. Adjusting engine idle speed.

(d) Stop engine and connect throttle control tube for

"B" engine and disconnect "D" engine.

b The throttle linkage may be adjusted after

(1) With engines stopped, set the throttle setting the

(e) Start "B" engine, declutch, and with master

valves, timing the injectors, adjusting the governor and

throttle in "FULL" open position, note and record speed.

the injector operating linkage as follows (fig. 4-27).

(f) If no-load speeds of the two engines are not the

control cross shaft (15, fig. 4-27) so that throttle control

same, increase the speed of low engine by adding shims

levers (17) are in a vertical position as shown at "A-A".

(5) between the high speed spring (4, fig. 4-27) and the

spring plunger (3). To add shims, remove low-speed

(2) With engines stopped, adjust turnbuckles

adjusting screw cover (1), back out nut (2), and place

(13 fig. 4-27) on the two throttle control rods so that pins

shims -between inner end of spring and shoulder on

in the throttle control levers at governor cover rest

plunger. Add one shim at a time and check speed after

against the shoulders of the control cams (8) in the

each shim is added.

"IDLE" position at the two governors.

(6) Synchronize engine speeds at no-load.

(3) Now move master throttle (16) to "FULL"

Speeds of the two engines must be synchonized to

open position, at which setting the pin in throttle lever

obtain, as nearly as possible, the same no-load speeds in

(24) at both governors should just strike the extreme end

the range just below the rated load speed by 'adjusting

of the slot in the cam (8) at the "RUN" position. If either

the linkage to each governor. Thus, a unit rated at 1,850

or both pins do not reach end of slot in cams, adjust

rpm should have the engines synchronized at 1,700-

turnbuckles (13) to bring about this condition. The linkage

1,800 rpm. Synchronize as follows:

must be so adjusted that the pins in the throttle ,levers at

governor covers reach "RUN" position in the control cam

(a) with engines warmed up, declutch both engines

at exactly the same time. Do not put any strain in the

and move master throttle to such ,position that speed of

throttle linkage when making this adjustment.

"B" engine is 1,750 rpm as -recorded by the tachometer.

Lock the master throttle in this position.

(4) Start and warm up both engines to

operating temperature. Move master throttle to "IDLE"

(b) Note speed of the "D" engine. If the speeds of

position. Declutch both engines and set idling speed of

the two engines are not the same, loosen the two

each engine to 500 rpm.

locknuts at turnbuckle on the '"D" engine, and by

adjusting turnbuckle, shorten throttle rod to increase or

NOTE

lengthen to decrease engine speed.

Engine may be brought up to operating

temperature by declutching engines and setting throttle to

(c) Unlock and move master throttle to "FULL" open

approximately 1,200 engine Wpm.

position. In the "FULL" open position, without strain on

the throttle linkage, the

4-29

|

||

|

||