| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-34

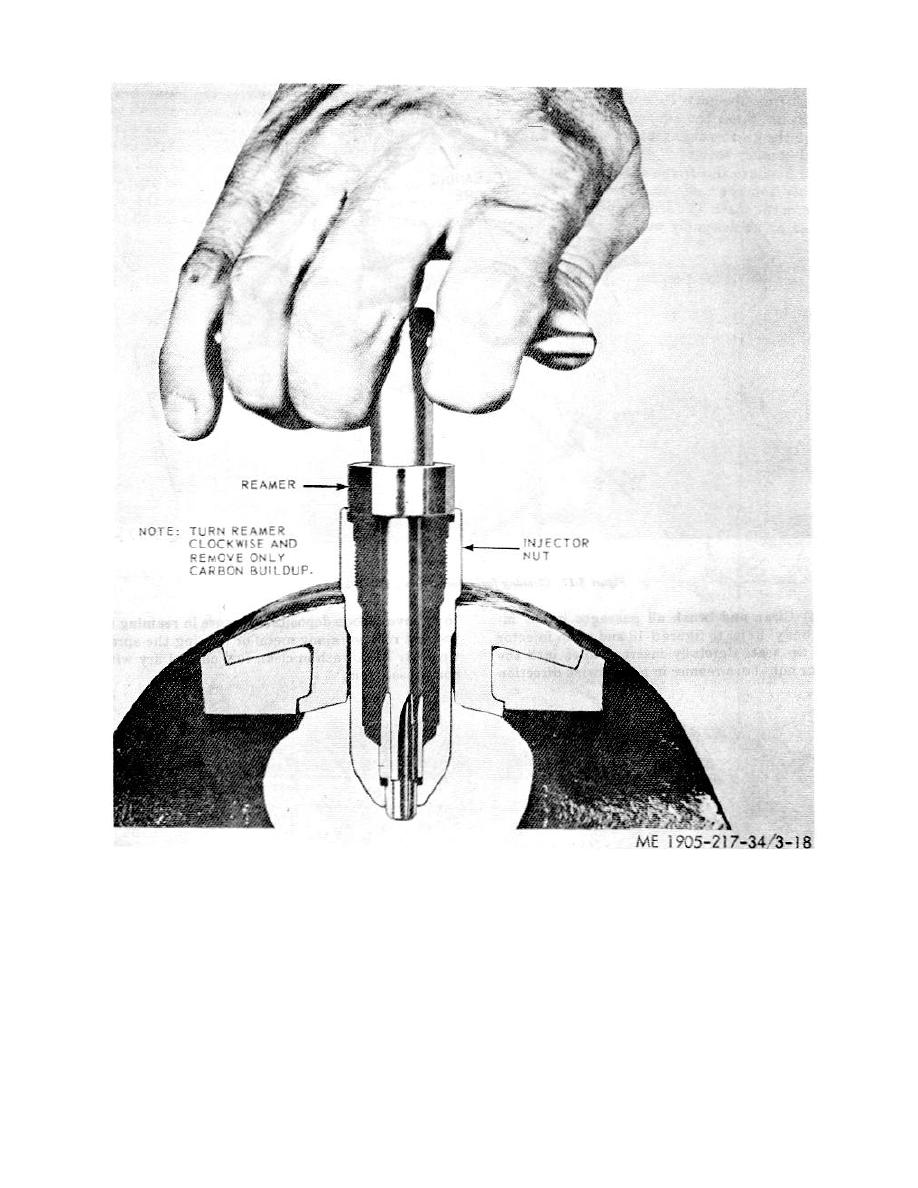

Figure 3-18. Cleaning fuel injector nut spray tip seat.

(5) When handling the injector plunger, do not touch finished plunger surfaces with the fingers. Wash

plunger and bushing with clean fuel oil and dry with filtered compressed air. Final clean with soft tissue paper.

Keep plunger and bushing together as they are mated parts. After cleaning, keep parts of each injector in

separate clean containers.

(6) Inspect the teeth on the control rack and control rack gear for excessive wear or damage. Inspect

both ends of spill deflector for sharp edges or burs which could create burs on the injector body nut. Remove

burs with a medium stone.

(7) Inspect follower spring for defects and proper tension. The spring has a free length of approximately

1.668 inches. Replace spring when a load of less than 48 lbs will compress it to 1.028 in length.

(8) Check the seal ring area in the injector body and the surface with contacts the injector bushing for

damage, if necessary, lap the surface (para (g) below). A faulty sealing surface at this point will result in a high

fuel consumption and contamination of the lubricating oil.

3-20

|

||

|

||