| Tweet |

Custom Search

|

|

|

||

TM 55-1905-222-14

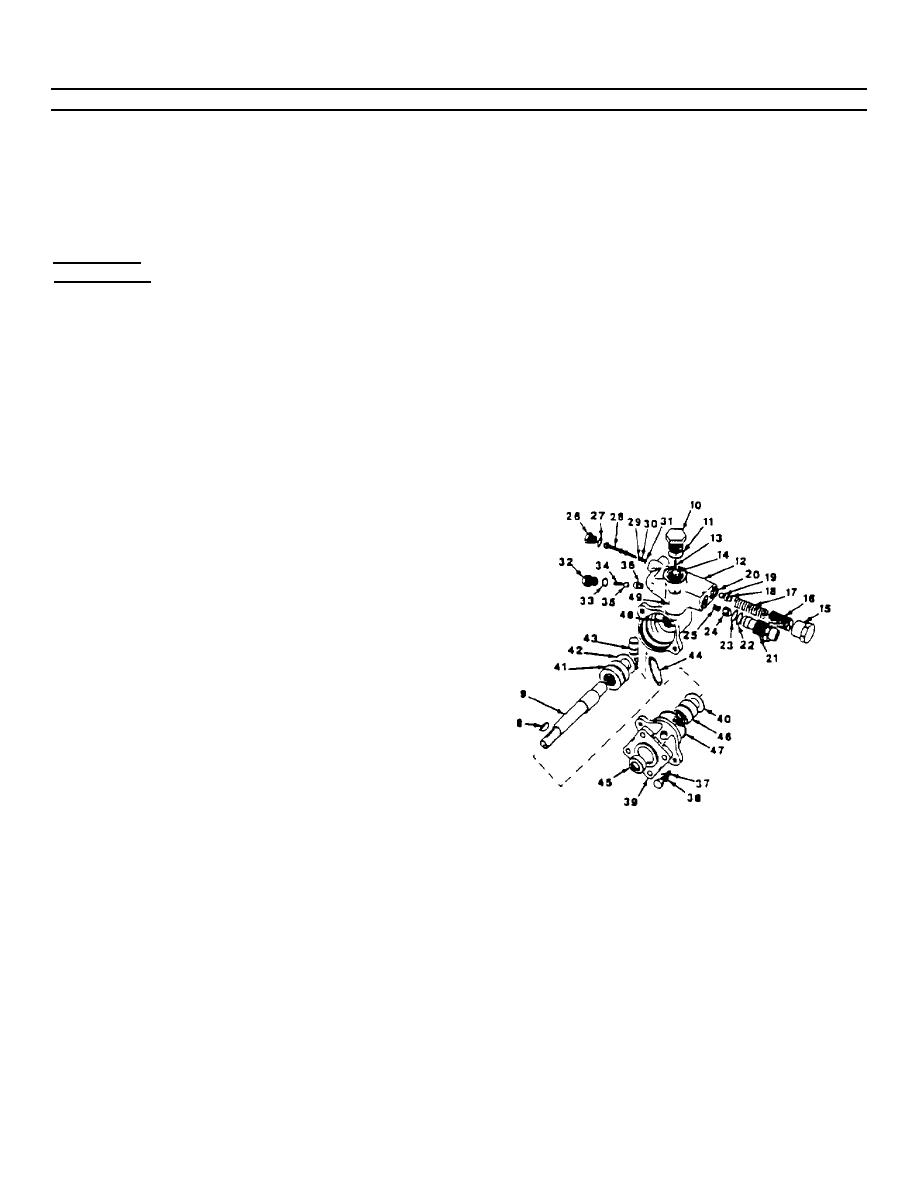

6-17 REPAIR RECHARGING PUMIP (Continued).

b. Blow dry all parts, except needle

bearings, with compressed air Allow

needle bearings to air dry.

c. Remove foreign material from bleed

hole of piston.

INSPECTION

1. INSPECT PUMP COMPONENTS

a. Discard all 'O' rings (11, 23, 27, 30, 33

and 47) and oil seal (45), replace with new

parts.

b. Examine springs (13, 17, 25 and 34) to be

sure that they are not bent, chaffed or

otherwise deformed, replace springs as

necessary.

c. Inspect all check balls (14, 19, and 35)

and valve seats (18 and 36) for scoring or

other damage, replace as necessary.

d. Inspect piston (43) for scratches or

scoring, replace as necessary

e. Examine shaft (9) to be sure that it is free

of burrs Check to be sure the keyway is

not broken or rounded over, replace as

necessary

f. Inspect needle and roller bearings (41, 46

and 48) for wear, scoring, or grooving,

replace as necessary.

g. Examine pump housing (12) for cracks or

other damage.

Check threads for

damage; replace as necessary.

6-90

|

||

|

||