| Tweet |

Custom Search

|

|

|

||

TM 55-1905-222-14

6-23

REPAIR PROPELLER AND PROPELLER SHAFT (Continued).

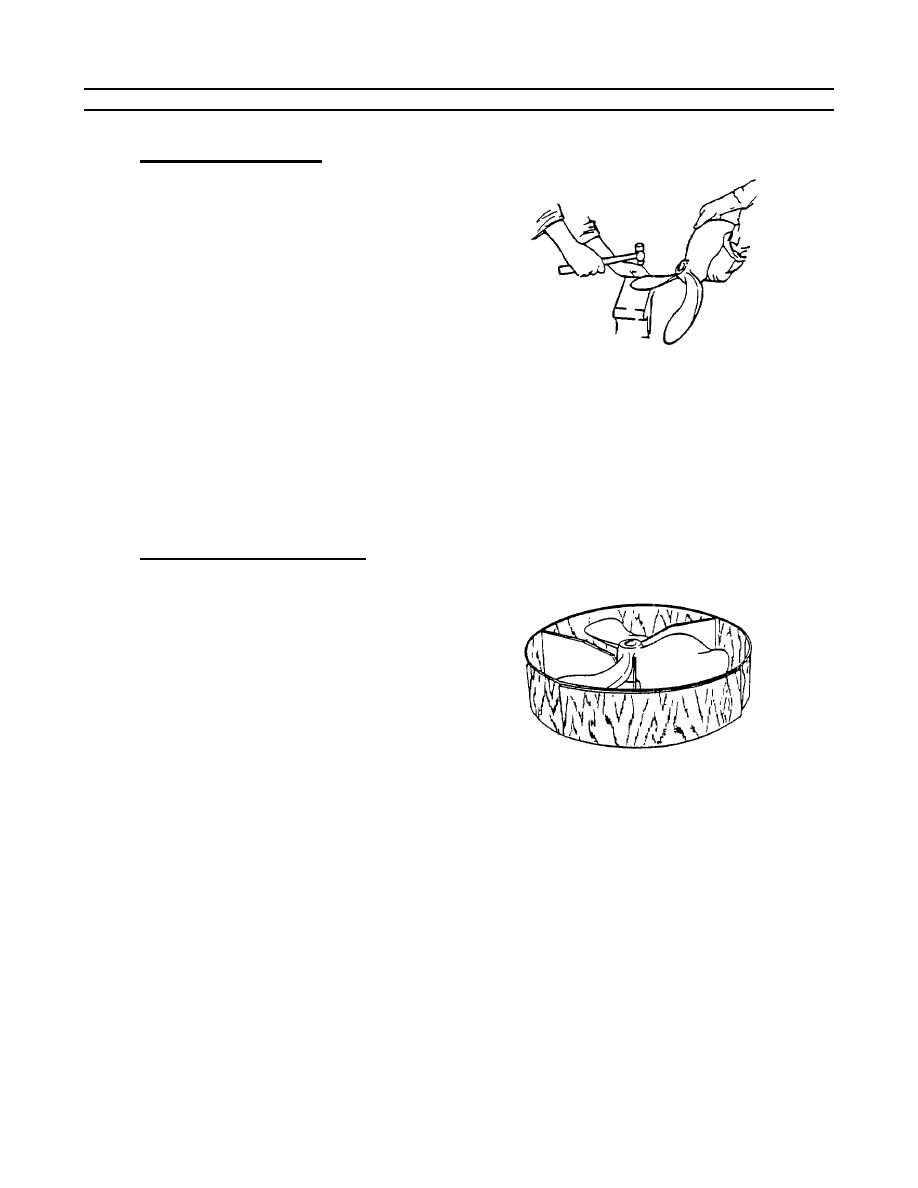

b. Straightening the Blade.

On small

propellers, tightly rolled bends are unrolled

with blacksmith's tongs. Other irregularities

are peened. It is advantageous to peen a

bend on its concave or hollow side. On

small propellers, strike the blade with a

light hammer while backing the peening

with the blade on an anvil. A typical

peening operation is shown at right. Large

propellers are peened by using air

hammers with a round edge caulking tool.

The metal unrolls like wet leather under the

hammer when the blade is at the correct

temperature. Work should be stopped and

the propeller reheated when the sound of

the metal under the hammer changes from

a dull, flat sound to a sharper, ringing

sound. Most blades can be reshaped with

two or three heatings. During straightening

operations the propeller should be

compared occasionally to a propeller pitch

block.

c. Making and Using a Pitch Block. A pitch

block can be made by pouring concrete in

a plywood box and shaping the upper

surface of the concrete to fit a new

propeller. The figure at right shows a badly

damaged propeller on a block before

straightening.

Refer to the figure showing the propeller on

the pitch block after straightening. In figure

at right the upper edges of the blade are

about an inch above the pitch block. This

is because the pitch block is for a propeller

with a pitch of 17 inches, where the

propeller is a 24 inch diameter propeller

with a pitch of 18 inches. An efficient

blacksmith with an eye for blade

configuration can determine the amount of

shaping and pitch alignment.

6-122

|

||

|

||