| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

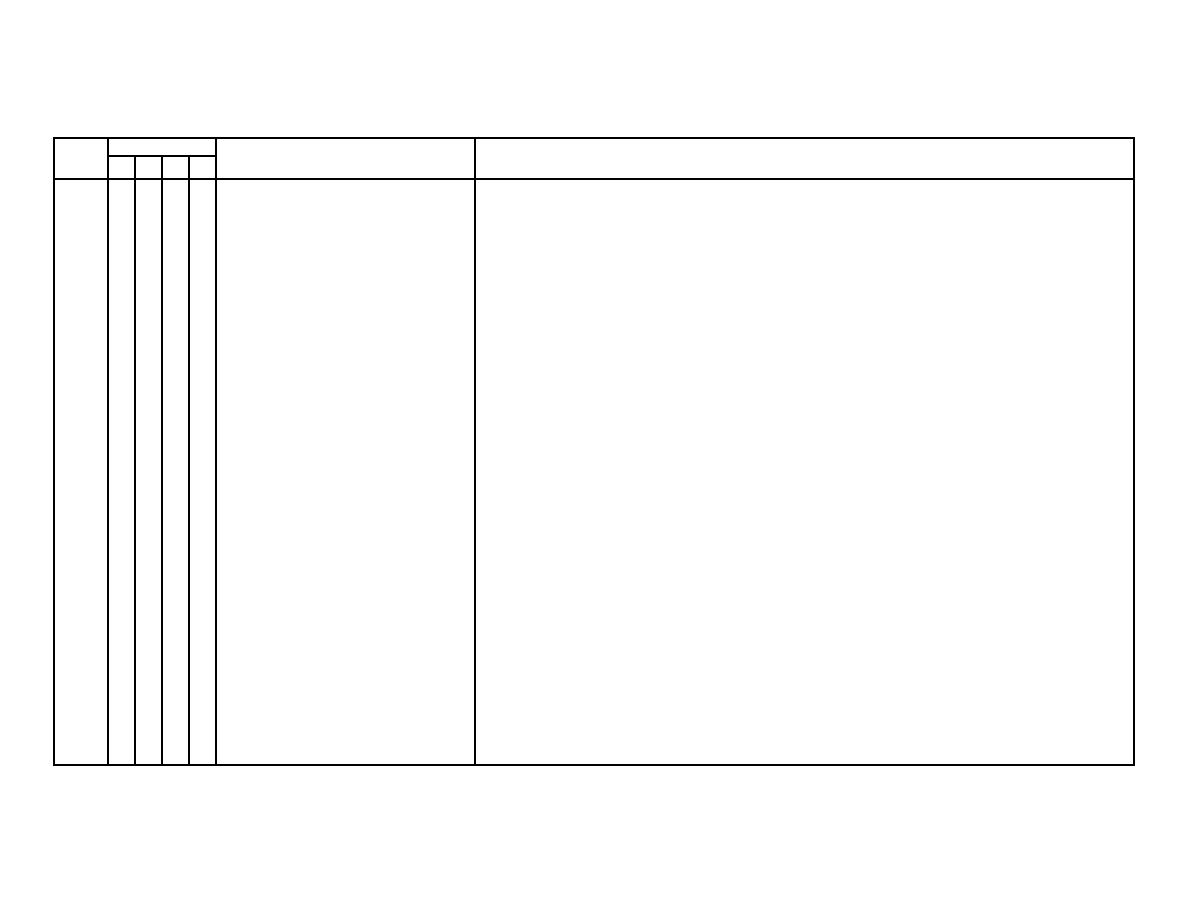

Table 2-1. Preventive Maintenance Checks and Services

D-Daily

Q-Quarterly

A-Annually

B-Biennially

Item

Intervals

Items To Be

No.

DQAB

Inspected/Serviced

Procedures

5

*

Exhaust System

Check exhaust manifold for exhaust leaks, water leaks, and corrosion. Check insulation

blankets (turbocharger also) to make sure that all hot surfaces are properly covered to

prevent any possibility of oil spraying on the hot surfaces.

*

Fuel, Lube and

Make sure there are no signs of abrasion. Make sure all hoses are properly connected.

Coolant Hoses

Make sure there is no seepage or leaks of hoses or fittings. Make sure cla ps are

m

tightened properly.

NOTE

Inspect under operating conditions with engine running. No twisting or bending force

should be applied during inspection, since flexible hose may "take a set" after being

in service.

*

Fuel Pump

Check for misadjustment, evidence of tampering, and leakage.

6

*

Lube Oil (or at

Change lube oil. The engine is provided with a manually operated sump pump located

every 250

at the right rear of the engine, mounted to the flywheel housing The output side of the

.

operating hours)

pump is connected to the "Dirty Lube Oil" tank. To change oil, proceed as follows.

Bring engine to operating temperature (175 to 195, then shut down. Wait 15 minutes,

)

then open the valve between the engine sump and sump pump. Be sure the valve to the

marine gear is closed. Turn the handle until all oil has been pumped from the oil pan. Close

valve when all oil has been removed. Fill the crankcase to the "H" mark on the dipstick or

on the sight gauge. Start engine and check for leaks. Shut down engine; allow 15 minutes

for oil to drain back into pan; recheck oil level. Add oil as required.

I

2-9

|

||

|

||