| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

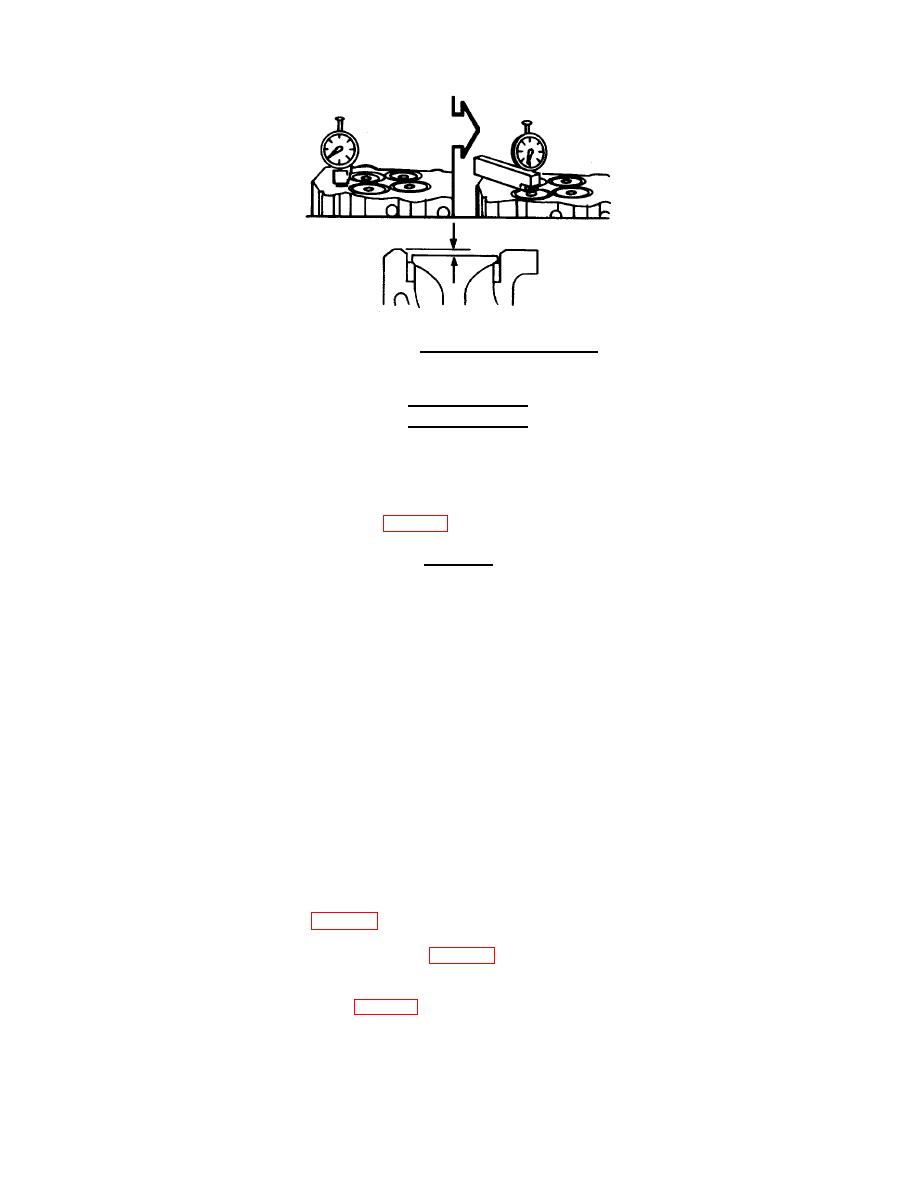

FIGURE 4-2.

Valve Depth Measurement.

b. Rebuild cylinder head.

WARNING

The valve springs are under compression. Use care when using

the valve spring compressor. Personnel injury can result if the

tool slips.

(1) Use valve spring compressor (1, FIG. 4-3) compress spring (5).

CAUTION

The collet groove in the valve stem can cut the valve stem seals

when the valve is removed. Pull the seal off of the guide and

carefully move it past the groove in the stem. If the seal is cut,

it must be replaced.

NOTE

Mark valves for location prior to removal. The intake and

exhaust valves are different. Marking valves will aid the

assembly procedure.

(2) Remove valve collets (2), spring retainer (4), spring (5), spring guide (3), and valve (8).

(3) Repeat procedure for each of four valves.

(4) Clean parts and check for broken springs, bent crosshead guides or other damage (refer to step a

of this procedure).

(5) Use a drill, a sheet metal screw and a slide hammer and hook from the light duty puller kit to

remove 10 cup plugs (FIG. 4-4).

(6) Measure free length of valve spring (5, FIG. 4-3). Verify spring length is approximately 3.35

inch (85.1 mm).

(7) Use a valve spring tester (1, FIG. 4-5). Measure spring (4) at working height (2) of 1.98 inch (50.3

mm). Verify spring force (3) is between 253 lb (1125 N-m) and 294 lb (1308 N-m).

4-8

|

||

|

||