| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-16

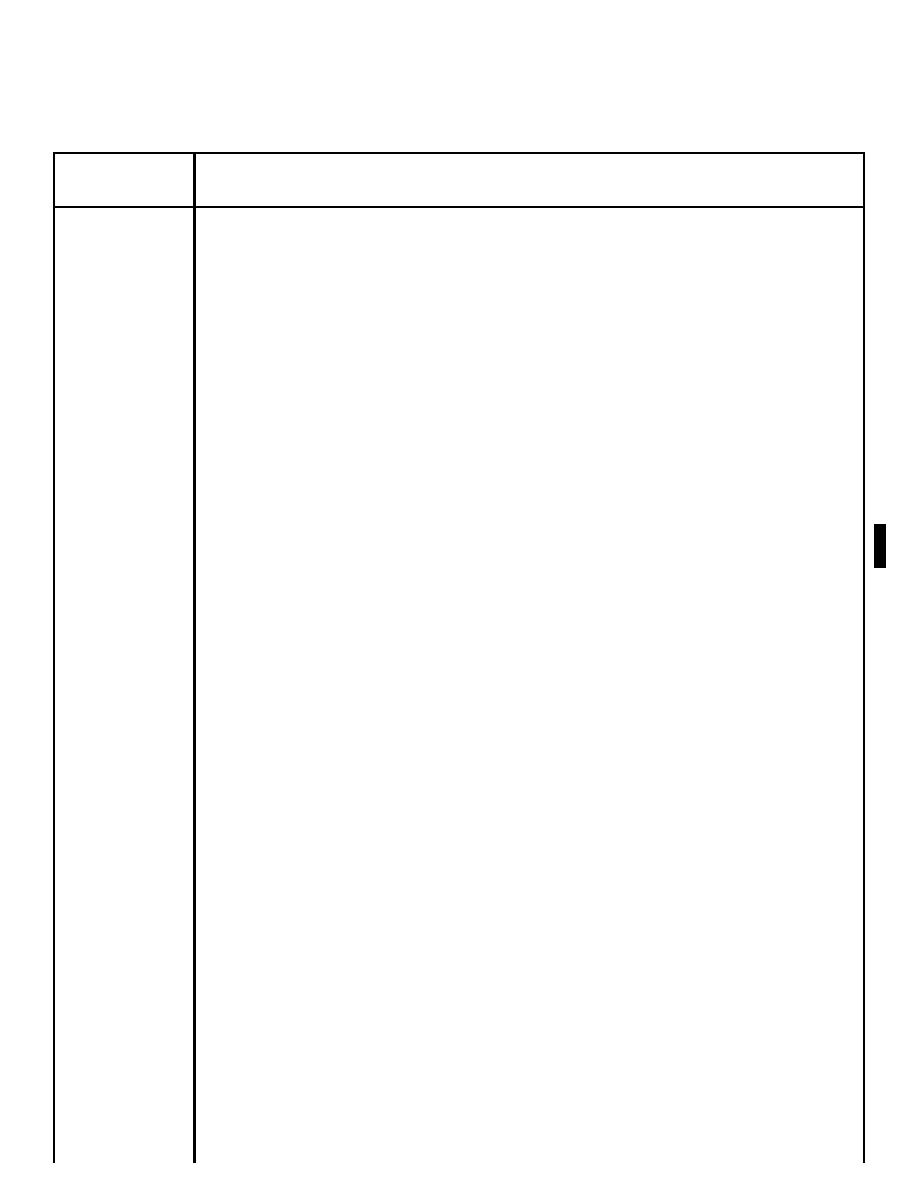

SECTION IV. REMARKS

FOR

STERN ANCHOR WINCH

Reference

Code

Remarks

A

WEEKLY:

GREASE ALL FITTINGS ON THE FAIR LEAD ROLLERS AND ASSOCIATED GUIDE

SLEEVES, IN ACCORDANCE WITH MAINTENANCE MANUAL.

B

WEEKLY:

GREASE FITTINGS INSTALLED IN THE CLUTCH SCREW, GYPSY WILDCAT, BRAKE

SCREW, BEARINGS AND CLUTCH ASSEMBLY, AND GEAR REDUCER.

C

THIS ITEM IS A CANDIDATE FOR DIRECT EXCHANGE WITH THE VENDOR

D

PROPER FLUID MUST BE USED FOR COMPATIBILITY TO SEALS AND OF VISCOSITY

RANGE RECOMMENDED BY THE COMPONENT MANUFACTURERS.

E

REMOVE PISTON FROM POWER PLATE BY INTRODUCING LOW P RESSURE AIR

(15 PSO INTO THE HYDRAULIC INLET. MAKE SURE PISTON IS DIRECTED AWAY FROM

OPERATOR.

F

CHECK THE RESERVOIR OIL LEVEL AND ADD OIL AS REQUIRED. THE LEVEL MUST

BE MAINTAINED BETWEEN THE HIGH AND LOW MARKS ON THE SIGHT GAGE.

G

CHECK THE OIL PRESSURE AND OPERATING TEMPERATURE. OIL PRESSURE AT

2900 PSI IS CONSIDERED MAXIMUM. TEMPERATURE AT 150 DEGREES F IS

CONSIDERED MAXIMUM.

H

AT LEAST ONCE EVERY SIX MONTHS, OR 2,000 HOURS OF OPERATION, THE

RESERVOIR, PUMP SUCTION FILTER, AND AIR VENT FILTER SHOULD BE CLEANED.

AT THIS TIME, CHECK THE ENTIRE SYSTEM FOR POSSIBLE FUTURE DIFFICULTIES.

I

AT 2,000 HOURS OR AT 6 MONTHS MAINTENANCE LEVEL, CHECK THE MOTOR/PUMP

COUPLING FOR MISALIGNMENT A FLEXIBLE COUPLING IS USED AND SHAFTS MUST

BE ACCURATELY ALIGNED PARALLEL AND ANGULARLY. CHECK SETSCREWS IN

COUPLINGS FOR LOOSENING. TIGHTEN AS REQUIRED.

J

DURING REPLACEIREPAIR OF HYDRAULIC SYSTEMS, ALL OPENINGS SHOULD BE

CAPPED/PLUGGED TO PREVENT FOREIGN MATTER OR CONTAMINATION FROM

ENTERING THE SYSTEM.

K

PERIODICALLY, CHECK OIL LEVEL IN SUMP OF GEAR REDUCER. OIL LEVEL TO BE

MAINTAINED TO LEVEL OF PLUGS ON SIDE OF UNIT.

L

MAJOR REPAIR/REPLACEMENT OF GEAR REDUCER WILL REQUIRE REMOVAL OF

WINCH AND GEAR REDUCER.

M

ATTACHING HARDWARE FOR THE HYDRAULIC MOTOR TO FAILSAFE BRAKE, AND

FAILSAFE BRAKE TO ADAPTER, IS SHOWN ON WINCH ASSEMBLY.

Change 3 B-7

|

||

|

||