| Tweet |

Custom Search

|

|

|

||

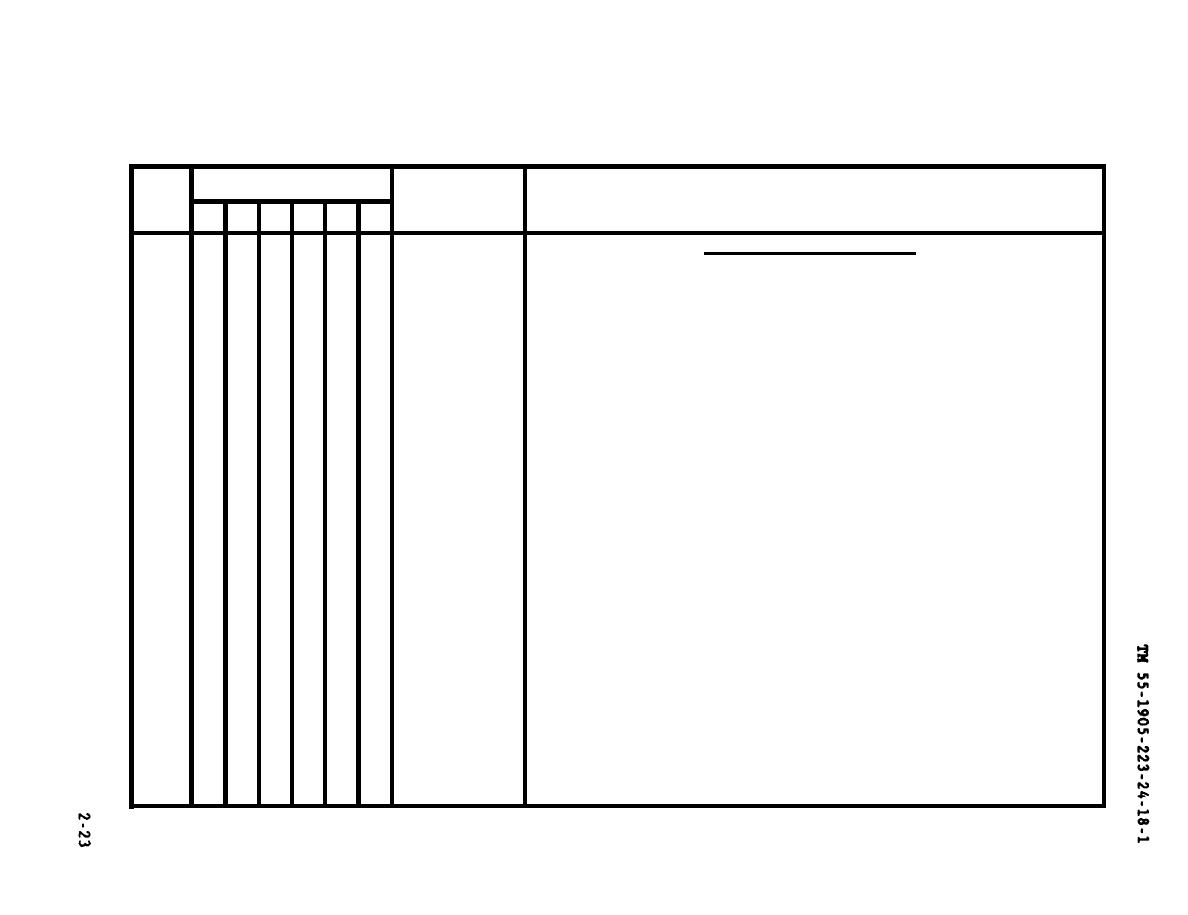

Preventive Maintenance Checks and Services - Cont.

Table 2-1.

S - Semiannually A - Annually

Q - Quarterly

D - Daily W - Weekly M - Monthly

Items To Be

Interval

Item

Procedures

Inspected/

Q

S

A

No.

D

W

M

Serviced

CONTROLS SYSTEMS - CONT

q

(3) Disassemble the component to expose all

Control Sub-

47

serviceable parts. Refer to individual component

systems -

assembly during disassembly and reassembly. Use a

Cont

clean, well-lighted work area.

NOTE

The lever assembly of the B202-1009 governor

actuator does not have to be removed as

bearings are prepacked. DO NOT submerge

lever assembly in solvent.

(4) Clean all parts (except rubber parts) with

petroleum base solvent, mineral spirits (Stoddard

solvent) or kerosene, and air dry. Clean rubber

parts with soap and water, then air dry.

(5) Ensure all parts are clean and free of residue.

Check all parts for wear, corrosion or damage.

Check diaphragms, "O" rings, and seals. Replace

if cracked, hardened, or worn.

(6) Replace all suspect parts. During assembly,

lubricate each part using Lubriplate No. 107 (Item

6, Appendix C) on metal to metal moving surfaces

and Pneumatic Grease No. 55 (Item 7, Appendix C)

on all rubber parts.

|

||

|

||