| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-5

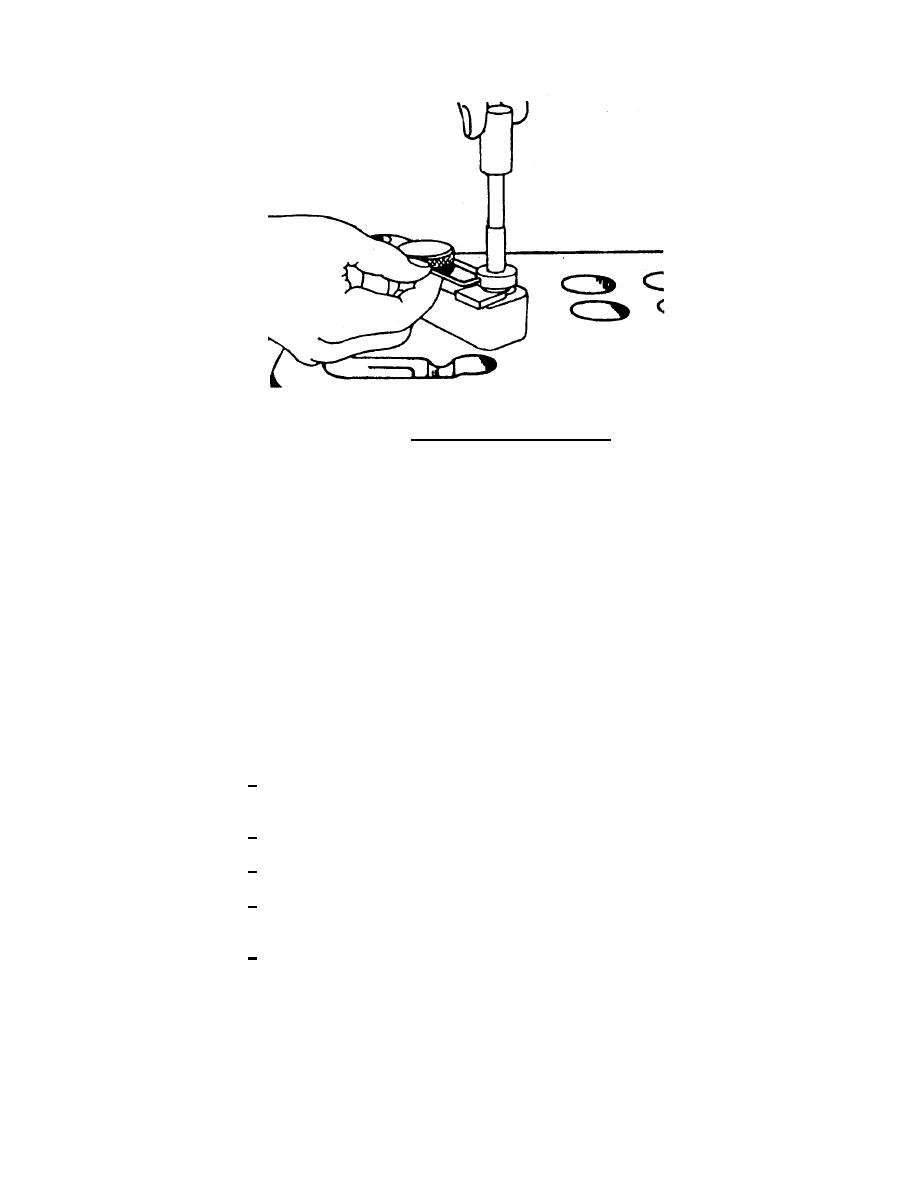

FIGURE 4-11. Adjusting Counterbore Cutter.

(e)

Insert the locating pin through the 5/8 inch bushing and into the water

hole to be repaired. Use your hand to tighten the adapter knob to

approximately 50 ft-lb. torque.

(f)

Remove the locating pin.

(g)

Install the counterbore cutter in the bushing.

(h)

Install the drive adapter in an electric drill.

(i)

Engage the drill adapter with the counterbore drill.

(j)

Start the drill. Apply minimum downward force while cutting the hole.

(k)

Remove the counterbore cutter and bushing plate from the cylinder head.

(1)

To install the water passage sleeve:

1

Make sure the hole is clean and all metal particles and sharp edger are

removed.

2

Slide the sleeve into the end of the bushing driver.

3

Apply a coat of sealant to the sleeve.

4

Align the sleeve with the water hole. Hit the bushing driver with a

hammer to install the sleeve into the water hole.

5

Cut the sleeve so that is even with the surface at the cylinder head.

Use a flat, wide mill file to cut the sleeve. Be careful not to damage

the surface of the cylinder head when you cut the sleeve.

4-22

|

||

|

||