| Tweet |

Custom Search

|

|

|

||

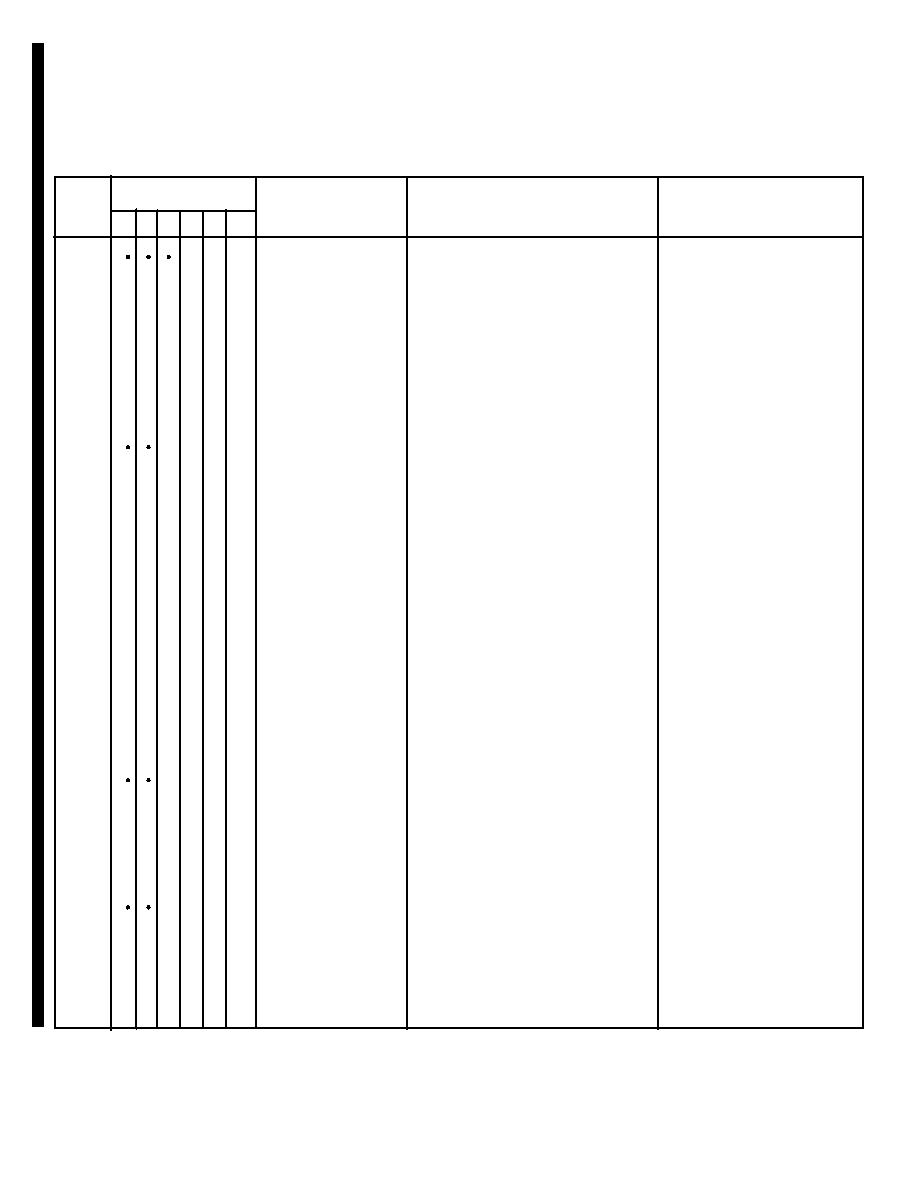

TM 55-1925-204-12

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

Tug Diesel Large Design 3006

B - Before

A - After

M - Monthly

D - During

B/A - Biannually

Q - Quarterly

Intervals

Item

Item To Be

Procedure

Equipment Will Be Reported

No.

BDA

M Q B/A

Inspected

Not ready/Available If:

46

Stern tube shaft

Check shaft packing gland during

Vessel is flooding through

packing gland

operation for excessive leak off

shaft packing gland.

and heat. Leakage should be-10-

15 drops per minute to lubricate

shaft bearing and packing.

Should it become necessary to

tighten gland, ensure bolts torque

is staggered to afford even move-

ment on packing gland. Use lock

nuts to stop torque nuts from

vibrating loose.

47

Fuel system

Check quantity of fuel in tanks,

Transfer pump is inoperative.

noting any indication of leaks.

Excess water is evidenced

Add fuel to top-off as necessary.

in fuel system.

Tank capacities:

Fuel oil tanks (7) 21

214 gals

Day tank

300 gals

Galley range tank

30 gals

Lubricating oil

450 gals

Dirty lube oil

395 gals

Sludge tank

50 gals

Check service tanks with sound-

ing tape. Inspect fuel oil transfer

pump for leaks and proper opera-

tion (15 GPM at 25 psi). Ensure

relief valve lifts when pump

discharge valve is closed. Check

tank vents co insure flame ar-

restor is installed, and free of rust

and corrosion. Ensure ball check

valve operates correctly - ball free.

Warning

Day tank overflows into number

48

four service tank port side. En-

sure inner bottom fuel oil storage

tank (4 port) is at a level to accept

overflow. Keep tank at 70%

capacity or below, to prevent oil

spillage from day tank overflow.

49

Fire and salvage

Ensure pump, line and strainers

Fire and salvage pumps

pump

are in good repair and properly

are inoperable in fire and

mounted. Check piping for leaks,

salvage situation.

and ensure suction and discharge

valves are in good repair and

operational. Ensure pump is lined

up prior to starting. Open suction

3-8.10

Change 1

|

||

|

||