| Tweet |

Custom Search

|

|

|

||

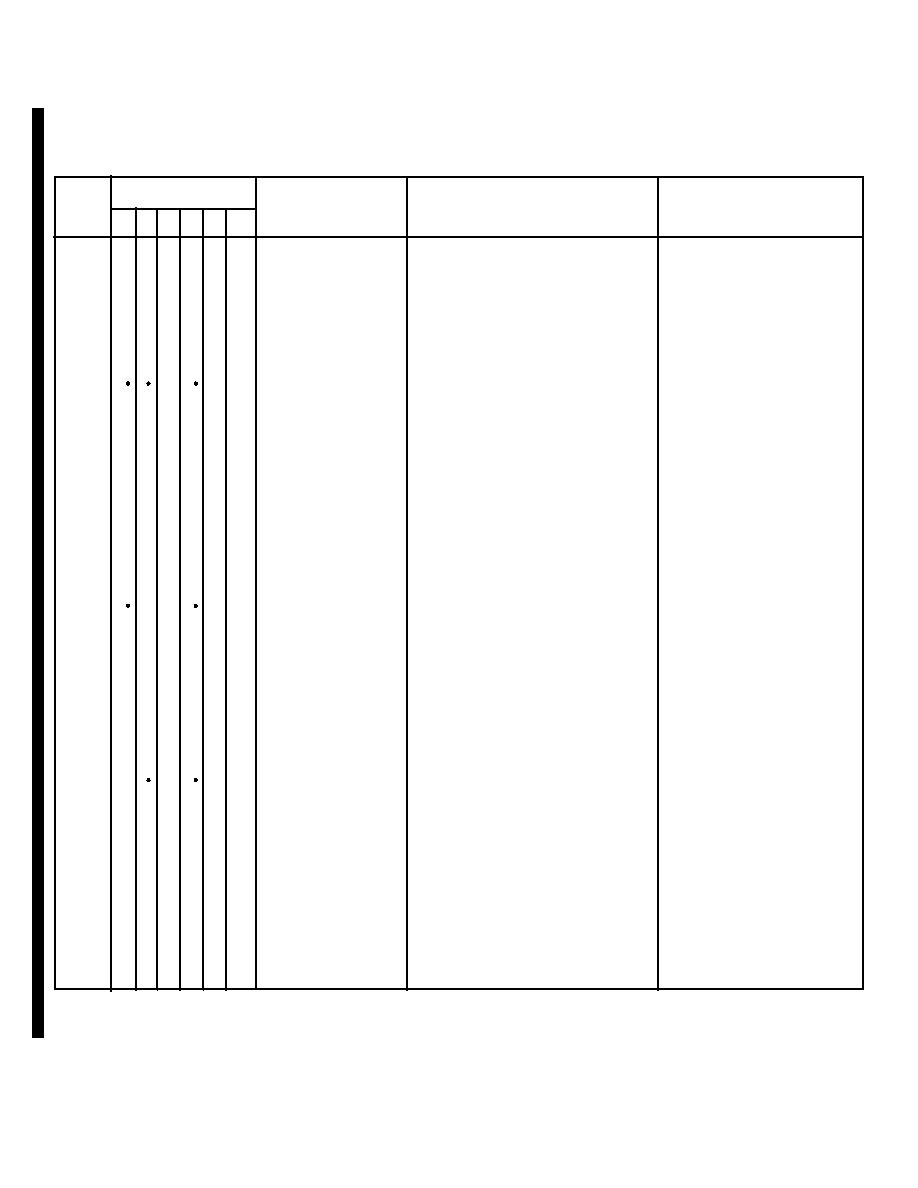

TM 55-1925-204-12

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

Tug Diesel Large Design 3006

B - Before

A - After

M - Monthly

D - During

B/A - Biannually

Q - Quarterly

Intervals

Item

Item To Be

Procedure

Equipment Will Be Reported

No.

BDA

M Q B/A

Inspected

Not ready/Available If:

and altitude gauge for pressure in

vessel heating system. Maintain

burner unit IAW LO55-1925-205-

12-1. Boiler electrodes should be

pulled periodically, cleaned, gap-

ped and reinstalled. Check Navy

manual for gap setting.

54

Ventilation system

Check all fans, blowers, filters,

Ventilation is impaired

screens, dampers, ducts and

endangering safety of

mechanical exhausts to ensure

crew.

that they are in good condition,

secure and in satisfactory work-

ing order. Lubricate motors IAW

LO55-1925-205-12-1. Check line

start and stop switches for proper

operation. Ensure ventilation

outlets in mess-deck, galley, living

spaces, and engine spaces are

functioning correctly; with adequate

discharge and no restrictions.

55

Fire extinguishers

Inspect for corroded nozzles/

Required fire extinguishers

damaged hoses. Ensure seal is

are not on board vessel.

intact. Check weight of portable

cylinders monthly. Replace cylinders

under prescribed weight. Nonportable

should be visually inspected for

proper hook-up and intact seals.

At cyclic drydock period the non-

portable CO2 cylinders will be

tested IAW ships repair specifications.

Ships, electrical

Check power panel, ships service

No power available at

56

system

lighting, general lighting, black-

switchboard.

out light circuit, and primary cir-

cuits for proper installation and

operation. Ensure fuses are ap-

plicable to end item application.

Inspect all electrical wiring to en-

sure that it is securely connected,

clean and undamaged. Check in-

sulation for cracks and chafing.

Ensure kick pipes, conduits, and

shielding are secure and in good

repair.

3-8.12 Change 1

|

||

|

||