| Tweet |

Custom Search

|

|

|

||

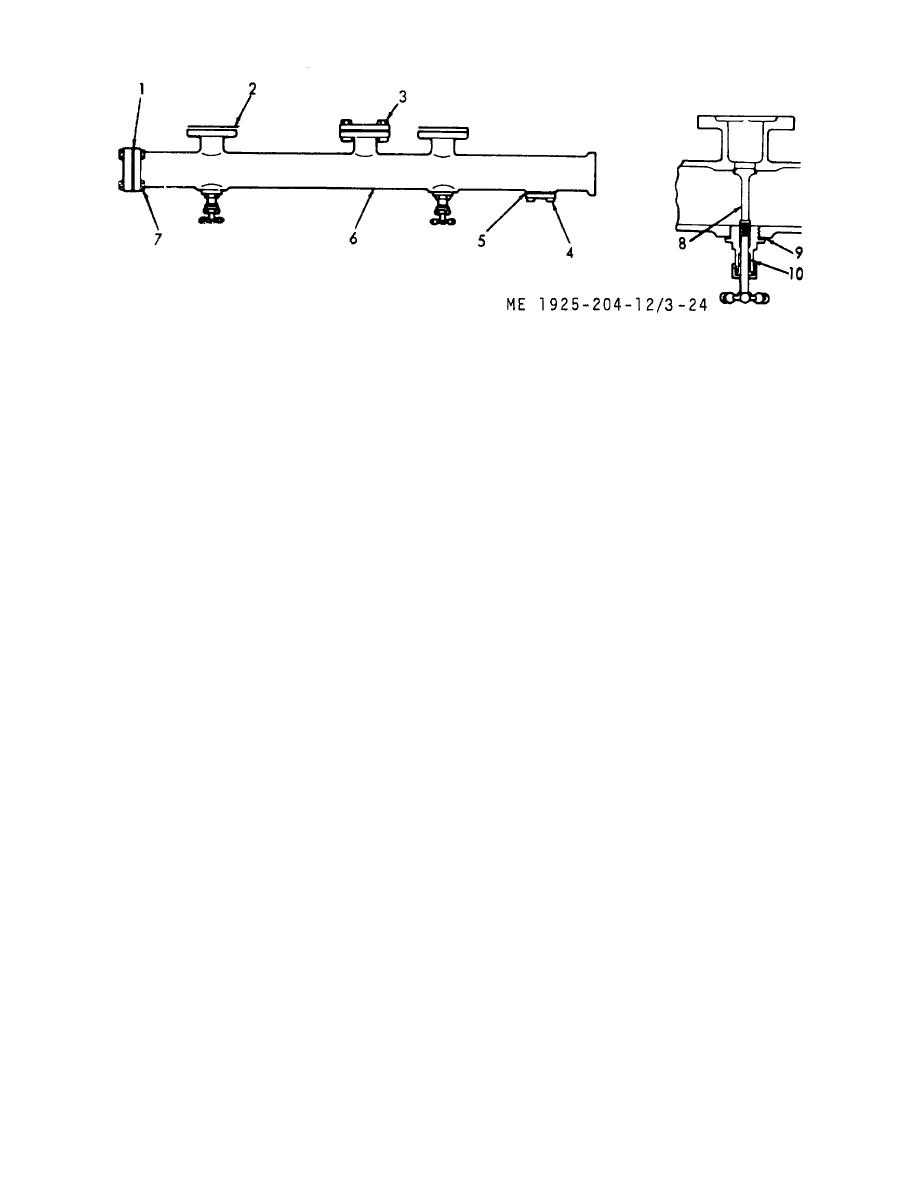

1.

Gasket

6.

Inlet header section

2.

Gasket

7.

Nut

3.

Capscrew

8.

Valve, regulating

4.

Capscrew

9.

Spacer ring

5.

Gasket

10.

Packing

Figure 3-24. Water inlet header and valve.

f. Thermostats (Thermometers).

Replace a broken or

NOTE

defective thermometer.

Watch the water level in the expansion

tank. If water rises abnormally, it may be

3-21. Heat Exchanger (Water Cooling)

due to a leak in raw water. If the level

a. General. The water cooling heat exchanger is mounted

drops, a leak in the fresh water line is

in a horizontal position, head high, on the starboard side of

indicated.

the engine room. It is a two pass cooler, with the fresh water

connections mounted on top so they do not form air pockets.

(3) Examine the valve stem carefully for corrosion, or

Raw water enters the side of the heat exchanger, flows

excessive scale formation.

through the inside of a cooling tube bundle and discharges to

(4) Inspect the inside of header visible through the

the overboard discharge. Baffles are located in the tube

valve port. Check valve seat carefully. When excessive scale,

bundle to. insure a flow of fresh water over the outer surface

or corrosion is seen, remove the water inlet header for repair

of all tubes. A bypass valve line is fitted to the heat

or replacement.

exchanger to provide a path around it should it become

c. Removal.

clogged, thus assuring a supply of cooling water to the

(1) Perform step (1) in b. above, then place a lifting

engine. Thermometers are installed at inlet and discharge

sling around the header. Connect the sling to a lifting device.

connections to indicate temperature of fresh water entering,

(2) Remove nuts from studs securing the header to the

and as it leaves the heat exchanger. Zinc corrosion eliminator

cylinders, steadying the header by tightening up the lifter

plates are installed in the heat exchanger to compensate for

device.

the electrolytic action of the raw water. The purpose of the

(3) Disconnect flanges of gaskets (1) by removing nuts

heat exchanger is to remove heat from the fresh water

(7), then remove header sections (6).

circulating through the engine. The operating temperature

d. Cleaning and Repair.

should range from 140 and 160 .

F

F

(1) Use the solvent MIL-C-11796B for cleaning the

b. Disassembly for Cleaning and Repair.

cooling system and remove the scale.

(1) Shutoff fresh and raw water to the heat exchanger.

(2) Clean the valves. Scrape scale or corrosion off the

Drain the heat exchanger.

valve seats and stems with a stiff brush. Soak to soften scale,

(2) Disconnect all inlet and outlet (fresh and raw) water

if necessary.

lines.

(3) Replace a defective spacer ring at bonnet.

(3) Remove the fresh water bypass line.

(4) Replace a defective performed packing.

(4) Remove the stationary endbell. Loosen the packing

(5) Replace a defective inlet header.

gland nuts on the floating endbell, then remove the endbell

e. Installation. Install the inlet header sections by

reversing the procedure in c. above, then removing the sling

and lifting device.

3-58

|

||

|

||