| Tweet |

Custom Search

|

|

|

||

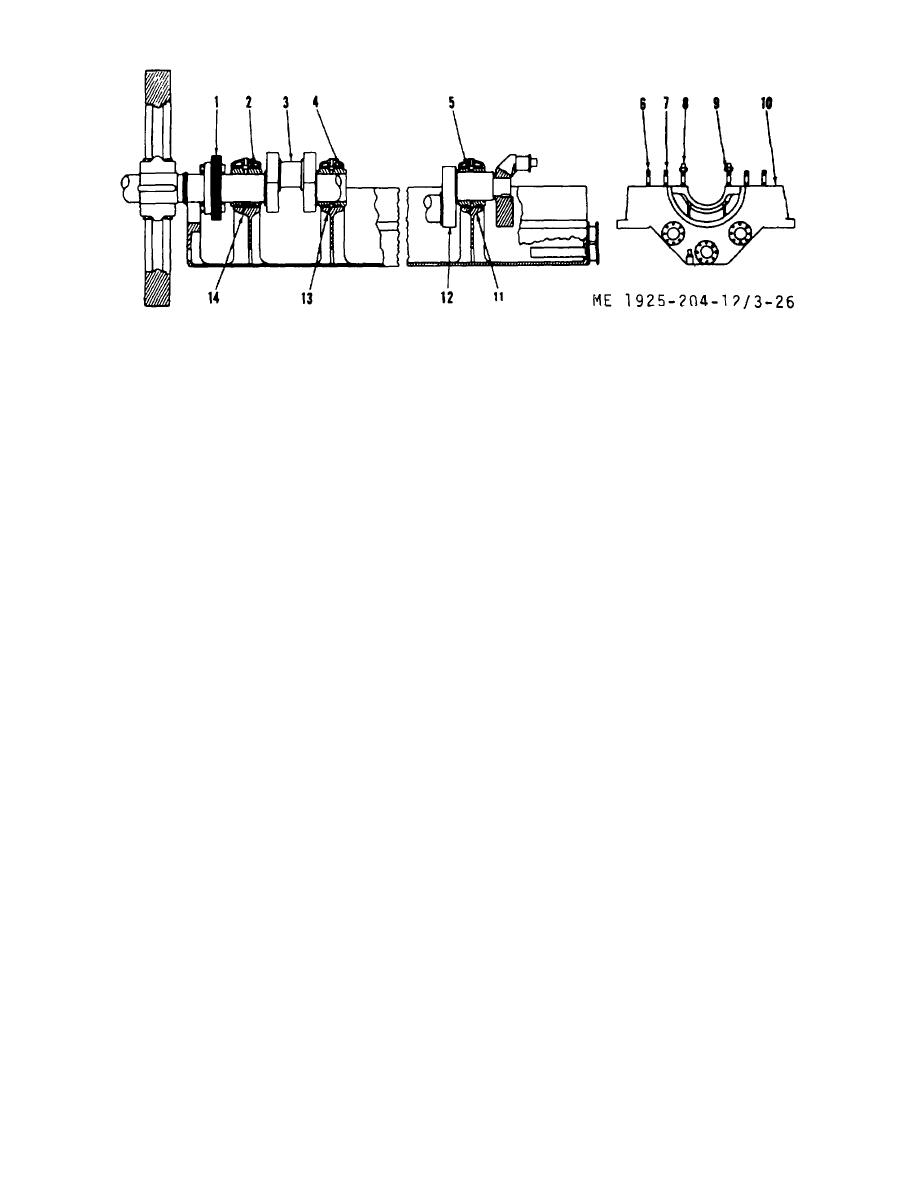

1.

Drive gear

8. Cap stud

2.

Bearing half

9. Stud nut

3.

Crankshaft journal

10. Shims

4.

Bearing half

11. Bearing half, lower

5.

Bearing half

12. Crank web

6.

Cap dowel

13. Bearing half, lower

7.

Shim dowel

14. Bearing half, lower

Figure 3-26. Crankshaft and main bearings.

(4) Place a small jack under the nearest crank web (12)

(6) Inspect the crankshaft bearing surface by feeling for

of the bearing to be removed. Jack the crankshaft up only

a slight ridge around, and in line with, crankshaft oil hole. If a

enough to take the load off the lower main bearing being

ridge is found, report to higher maintenance level.

removed.

d. Replacement of Main Bearing.

(5) Push lower half of main bearing (11) out of saddle

(1) To replace the main bearings proceed as follows:

bore and lift from crankshaft.

(a) Remove the old bearing (shell) from the

(6) Tag upper and lower bearing halves and bearing

bearing cap, upper half. Wash the bearing cap in clean fuel

cap for proper reinstallation identification.

oil and blow dry with compressed air.

c. Cleaning, Inspection, and Repair.

(b) Coat the back of the new bearing shell with a

(1) Before cleaning the bearing, check its surfaces for

thin coat of white lead and press the new bearing shell in the

the presence of "wet liquid oil." This is not an oil smear at the

bearing cap. Check to see that the bearing ends are flush

top of the bearing metal, but liquid oil that has collected

with the bearing cap.

during engine operation. When oil is present, the bearing is

(c) Coat the back of the new bearing shell (lower)

worn and must be replaced.

with a thin coat of white lead. Position the bearing on the

(2) Wash main bearing halves in clean fuel oil and wipe

crankshaft and roll the bearing into the saddle bore.

dry.

(d) Remove the small jack from under the crank

(3) Test the bond between the babbitt bearing (upper)

web.

and the steel back of the bearing cap by holding in one hand

(e) Lock the lower shell into position with clamps

and striking the steel back (bearing cap) with a hammer. It

bored to fit over the bearing studs. The clamps must be wide

should give a clear ringing sound. If a dull thud is heard, the

enough to cover the edges of the bearing metal without

bond between the bearing metal and its steel shell (bearing

touching the crankshaft. Use lengths of pipe to hold the

cap) has probably failed and the bearing should be replaced.

clamps in position and tighten with bearing stud nuts.

(4) Inspect the bearing surface to detect fine cracks.

(f) Coat crankshaft with a thin coat of Prussian

Fine cracks can be caused by a poor fit of the bearing shell in

blue and revolve crankshaft a few times.

its cap or saddle bore, overloading, or overspeeding of the

(g) Remove clamps holding the lower bearing in

engine. Replace bearings that are cracked, however slight.

position. Place the small jack under the crank web. Jack up

(5) Examine the bearing surface for pitting. When the

the crankshaft just enough to relieve weight from the lower

bearing is found to be badly pitted, replace the bearing.

bearing.

(h) Roll the lower bearing out and lift from

3-62

|

||

|

||