| Tweet |

Custom Search

|

|

|

||

TM 55-1925-204-12

NOTE

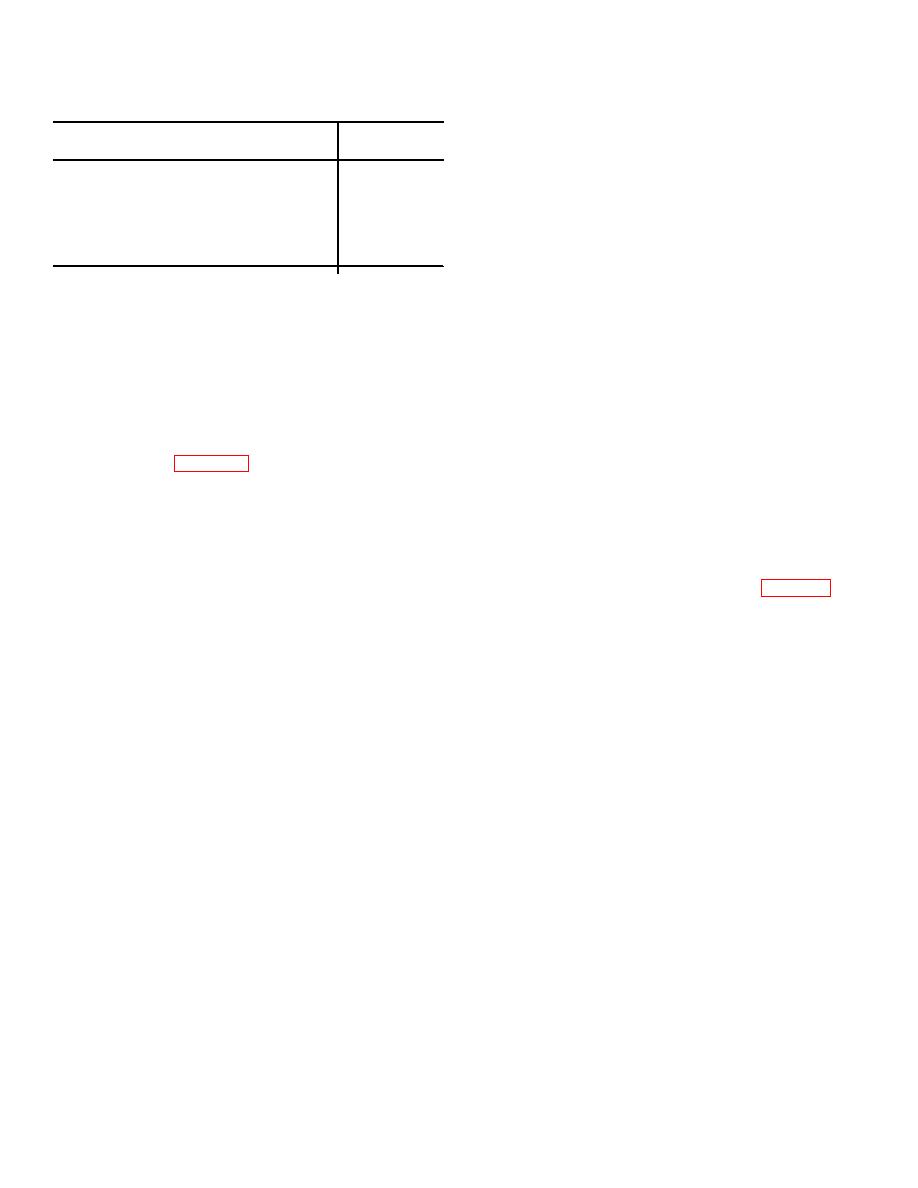

Table 4-4. Force Feed Lubricator Drop Count

It is recommended that a check be

Model 37F16 diesel engine, (at 300 rpm)

Drops per

made to determine if the established

lubrication point

minute

number of drops per minute for power

cylinders are correct for a particular

Power cylinders (3 lines to each cylinder)

35

installation.

Scavenging pump sleeve-lower

28

Scavenging pump sleeve-upper

7

(g) Remove an exhaust manifold hand

Lubricator drive rocker

7

hole cover and examine for traces of oil in the manifold.

Thrust bearing

28

Any traces in excess of between 2 to 3 inches beyond the

cylinder wall indicates that the lubricator feed is delivering

(b) Next, divide the listed number of

too much oil. Adjust accordingly, and annotate the

drops per minute by the determined number of impulses

change in the lubrication log book.

per minute; this establishes the number of drops per

c. Scavenging Oil Transfer Pump (#5130). This

impulse, at which the feeds should be set.

transfer pump, electric motor driven, has a capacity of 3-

(c) With the engine stopped, and the oil

l/2 gpm, and is located on port side of the engineroom at

at operating temperature, turn the lubricator hand crank

forward bulkhead. Its purpose is to move oil collected by

one complete revolution, and count the number of oil

the scraper rings from the force feed lubricator supply to

drops falling into the cup for the particular line being

engine cylinder walls, directly to the purifier for removal of

checked.

carbon before its return to the system for reuse.

(d) If an adjustment is required, turn the

(1) Removal.

adjusting screw (fig. 4-10) clockwise to decrease, or

(a) Disconnect the 3/8 in. oil line from

counterclockwise to increase.

the pump suction inlet. Tag and disconnect all electrical

(e) Repeat steps (c) and (d) until the

leads.

number of drops per minute are as required for that feed.

(b) Remove the motor and pump from its

(f) Repeat steps (c), (d), and (e) above

mounting.

for each lead, until the lubricator is adjusted to feed

(2) Disassembly of pump.

correctly.

(a) Separate the motor and pump.

(b) Remove two nuts (6, fig. 4-13) and

the packing gland (5).

4-24

|

||

|

||