| Tweet |

Custom Search

|

|

|

||

TM 55-1925-273-10-1

0017 00

2

3

1

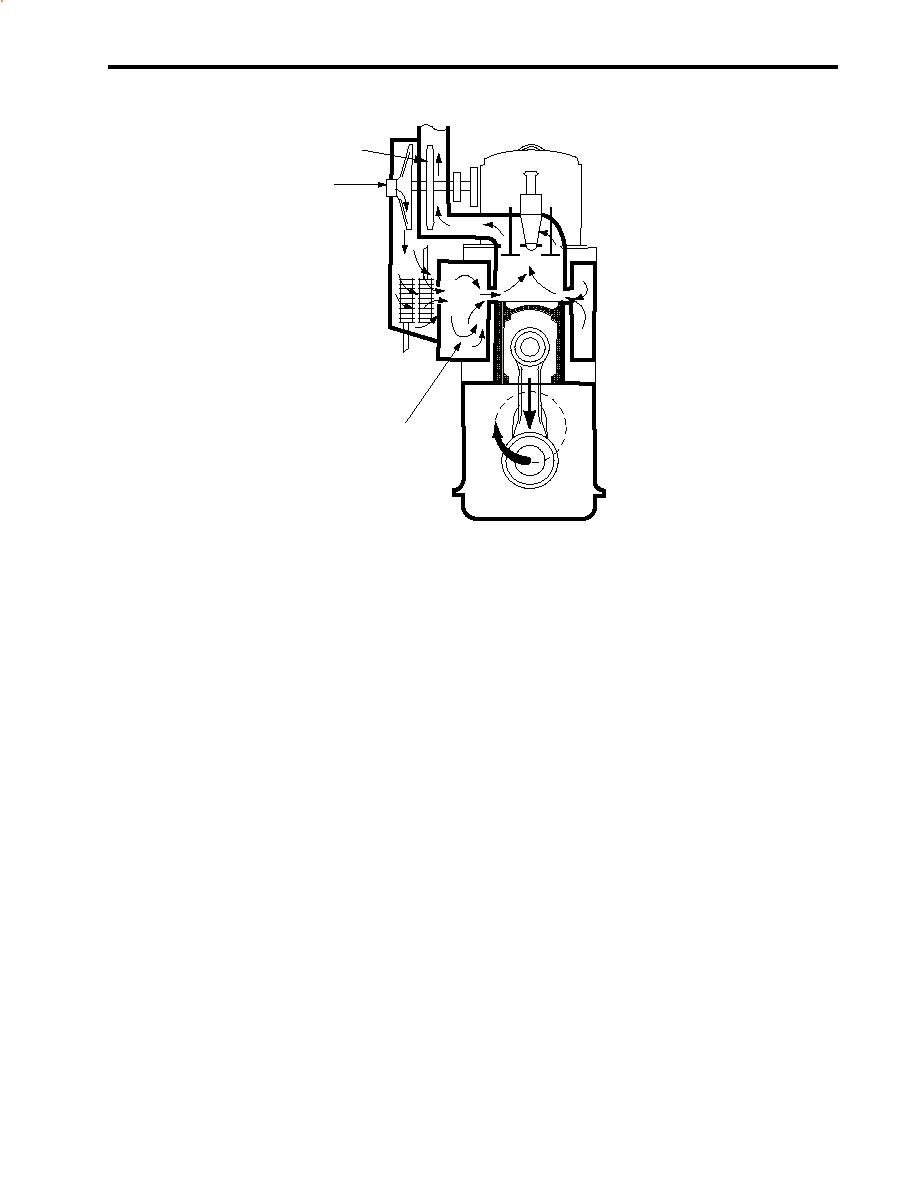

Figure 2. Engine Operation and Air Starting System

ENGINE EXHAUST SYSTEM

Exhaust gases from the engine cylinder are discharged from the cylinder heads into the exhaust manifold and turbocharger

turbine (figure 2, item 3). Going through the turbine, the gases pass through the turbocharger ducting, up the stack, and to the

atmosphere. The engine exhaust also has condensation drain lines and temperature sensors.

AIR STARTING SYSTEM

The engine air starting system consists of a lower air starting motor (figure 3, item 1), an upper air starting motor (figure 3,

item 2), a strainer (figure 3, item 3), a solenoid valve (figure 3, item 4), an air start valve (figure 3, item 5), an air line

lubricator (figure 3, item 6), a shutoff valve, and the start button. Compressed air at 200 PSI (14 bar) is supplied from the

vessel's starting air system. When the start button is pushed, the solenoid valve is energized (to the OPEN position),

allowing air from the starting air system to pass through the solenoid valve and strainer to the pinion gear area of the lower

starting motor (figure 3, item 1). A throttle interlock prevents starting of the engine if the throttle is not in the NEUTRAL

position. The air entering the pinion gear area moves the pinion gear forward to engage with the engine ring gear. Move-

ment of the pinion gear uncovers a port, allowing air pressure to enter the upper starting motor (figure 3, item 2) which, in

turn, engages its pinion gear with the ring gear. With the pinion gears now engaged, air is released from the uncovered port

in the upper motor. In addition to maintaining gear engagement, the air opens the air start valve, releasing the main starting

air supply. Air passes through the air start valve and into a flexible hose assembly connected to each air starting motor. The

multivane motors drive the pinion gears, rotating the ring gear, cranking the engine.

Both pinion gears must be engaged to start the engine. The system is designed so that no attempt can be made to start the

engine using one motor. There is also a manual cutoff valve in the system. When maintenance is being performed, the cutoff

valve is closed to prevent accidental cranking of the main propulsion engine being serviced.

0017 00-3

|

||

|

||