| Tweet |

Custom Search

|

|

|

||

TM 55-1925-273-10-2

0120 00

START THE PORT PROPULSION PLANT

1.

Ensure that the air compressors are online and that the starting air receivers are pressurized to 250 PSI (17.2 bar). If the

compressors are not online or the starting air receivers are not charged, START the air compressors (TM 55-1925-286-

13&P).

2.

Check that the coolant level in the port main engine coolant expansion tank sight glass (figure 1, item 1) is between

LOW and FULL in the STOP range (figure 1, item 2). If the coolant is not between LOW and FULL, add coolant

through the fill cap (figure 1, item 3) until the proper level is achieved. Proper engine coolant is a 50/50 mix of ethylene

glycol antifreeze and water.

3.

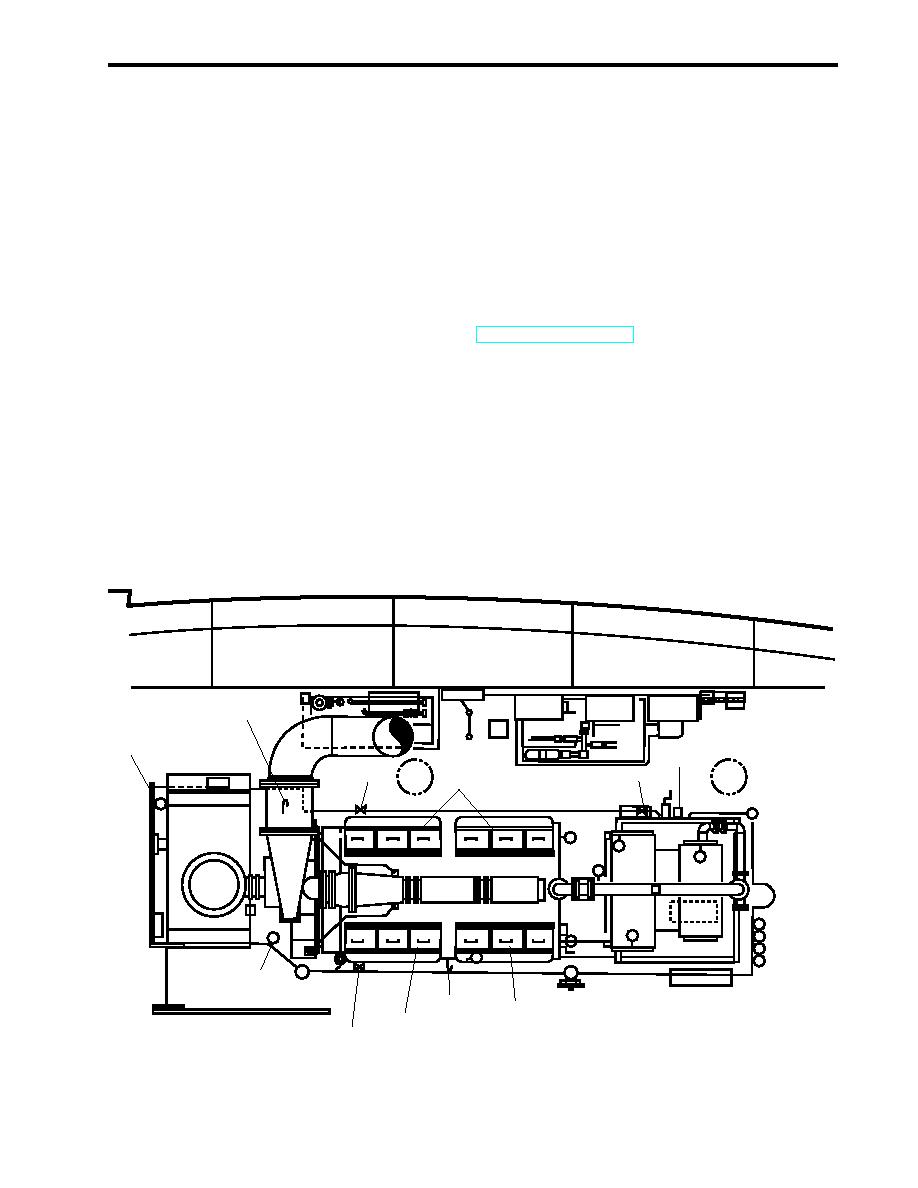

Check that the port main engine oil is at the normal level on the dipstick (figure 13, item 1). If the engine oil level is low,

add oil until the proper level is achieved. Refer to TM 55-1925-208-24 or maintenance supervisor for oil specification.

4.

Check that the port reduction gear oil is at the normal level on the dipstick (figure 13, item 2). If the reduction oil is level

low, add oil until the proper level is achieved. Refer to TM 55-1925-223-24&P or maintenance supervisor for oil

specification.

5.

At 440V power panel No. 1, set the following circuit breakers to ON:

a.

FRESH WATER PUMP No. 2, (REDUCTION GEAR) (figure 3, item 4).

b.

MAIN ENGINE LUBE OIL PRIMING PUMP No. 2. (figure 3, item 5).

c.

MAIN ENGINE JACKET WATER HEATER No. 2/TURBO OIL PUMP No. 2./WATER LAY OVER PUMP

No. 2. (figure 3, item 6).

6.

Allow the main engine jacket water heater to run for at least 8 hours before continuing with this procedure.

2

5

4

3

7

6

8

1

6

6

7

Figure 13. Port Main Engine and Reduction Gear

0120 00-11

|

||

|

||